Rapid maturation method of distilled wine by light and heat treatment

A technology of distilling wine and photochemical light, which is applied in beer fermentation methods, biochemical equipment and methods, and beer brewing, etc. It can solve problems such as failure to seize market opportunities, failure to maximize investment, and difficulty in predicting the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0107] Example 5: Mixed batch heating and actinic light process

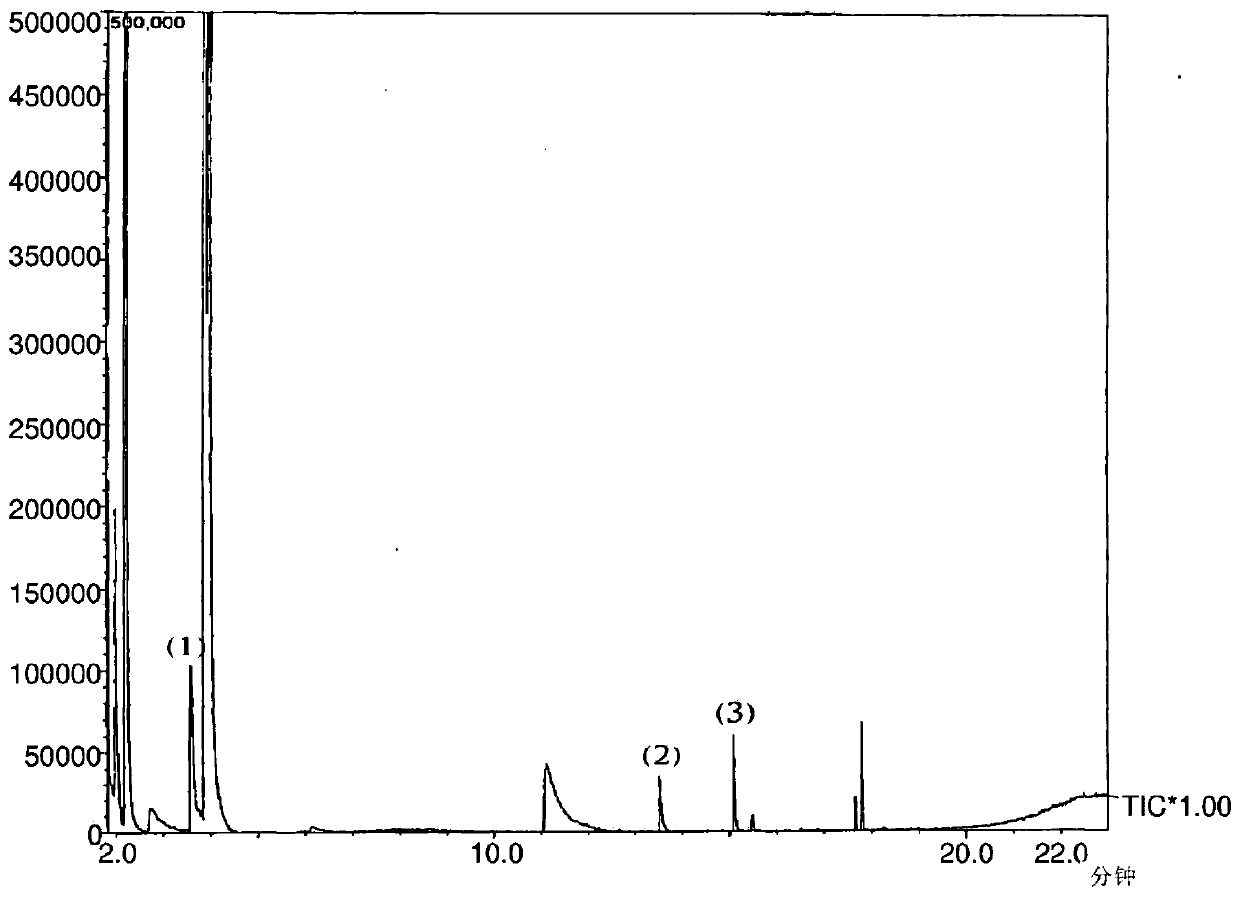

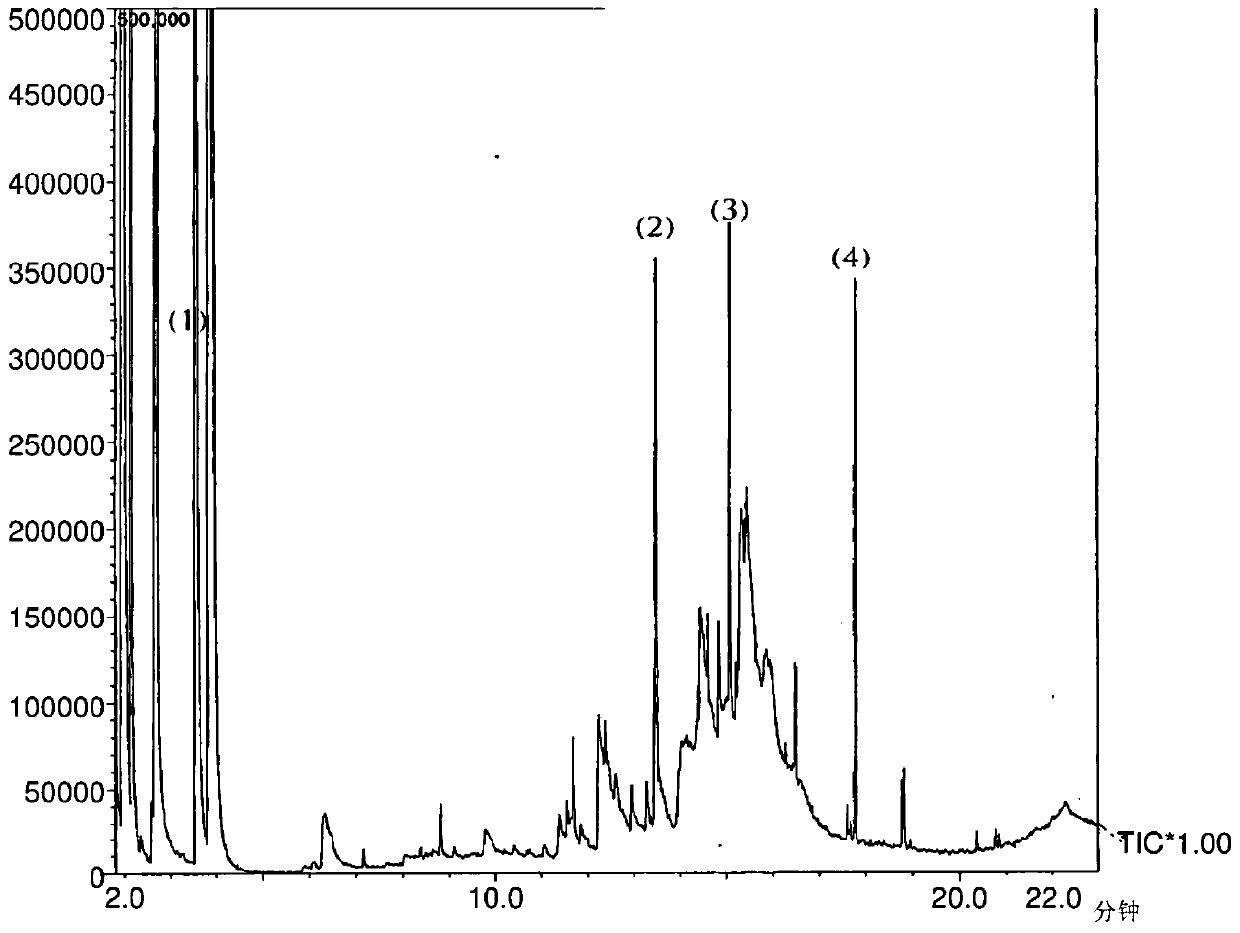

[0108] Untreated, pot still rum is added to stainless steel tanks, mixed with charred oak planks and heated to between 150°F and 170°F. Keep the temperature in this range for 48 hours. Separately, untreated pot-distilled rum was placed in airtight flint glass bottles with charred oak panels and held in a greenhouse for 30 days. The heat-treated product and the light-treated product were then mixed together in a proportion of 60% heat-treated product and 40% actinic light-treated rum. The mixture was allowed to react for 24-48 hours. After this period of time, the resulting product was analyzed by GCMS. Figure 5 GCMS chromatograms are shown. This chromatogram shows some unexpected results as well as important developments. The concentration of acetyl groups (peak 1) unexpectedly decreased below that of either of its constituents ( image 3 and Figure 4 ). However, the level of acetal compared to untreat...

Embodiment 6

[0110] Example 6: Sequential temperature and light treatments

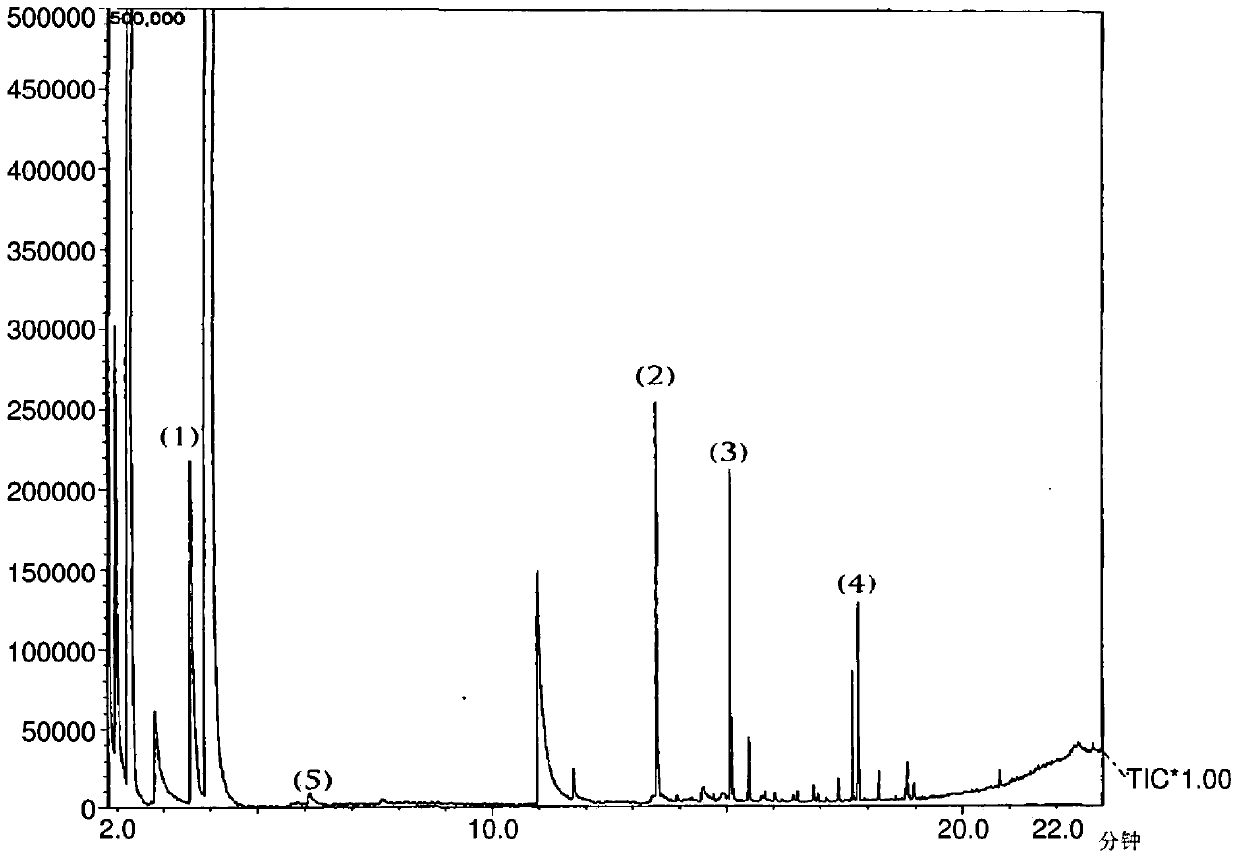

[0111] Untreated, pot still rum is added to stainless steel tanks, mixed with charred oak planks and heated to between 150°F and 170°F. Keep the temperature in this range for 48 hours. The resulting product was then placed in a sealed flint glass bottle along with a charred oak board and placed in front of a 500W halogen bulb for 3 days. 70 glass vials were placed on a rack surrounded by a total of 20 lights. Toggle the light on and off in 2-4 hour cycles to prevent boils. The resulting product is then placed in stainless steel tanks, mixed with charred oak planks and heated to between 150°F and 170°F. Keep the temperature in this range for 48 hours. The resulting product was analyzed by GCMS.

[0112] Figure 6 The GCMS chromatogram of a rum sample that has been treated with both heat and light according to Example 6 is shown. It shows some surprising results as well as important developments. and Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com