New type non-agitating kettle with two regions for esterifying polyester

A technology of esterification kettle without stirring, which is applied in the field of polyester esterification kettle, and can solve the problems of high energy consumption, large number of kettles, and large entrainment of precondensation gas phase mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

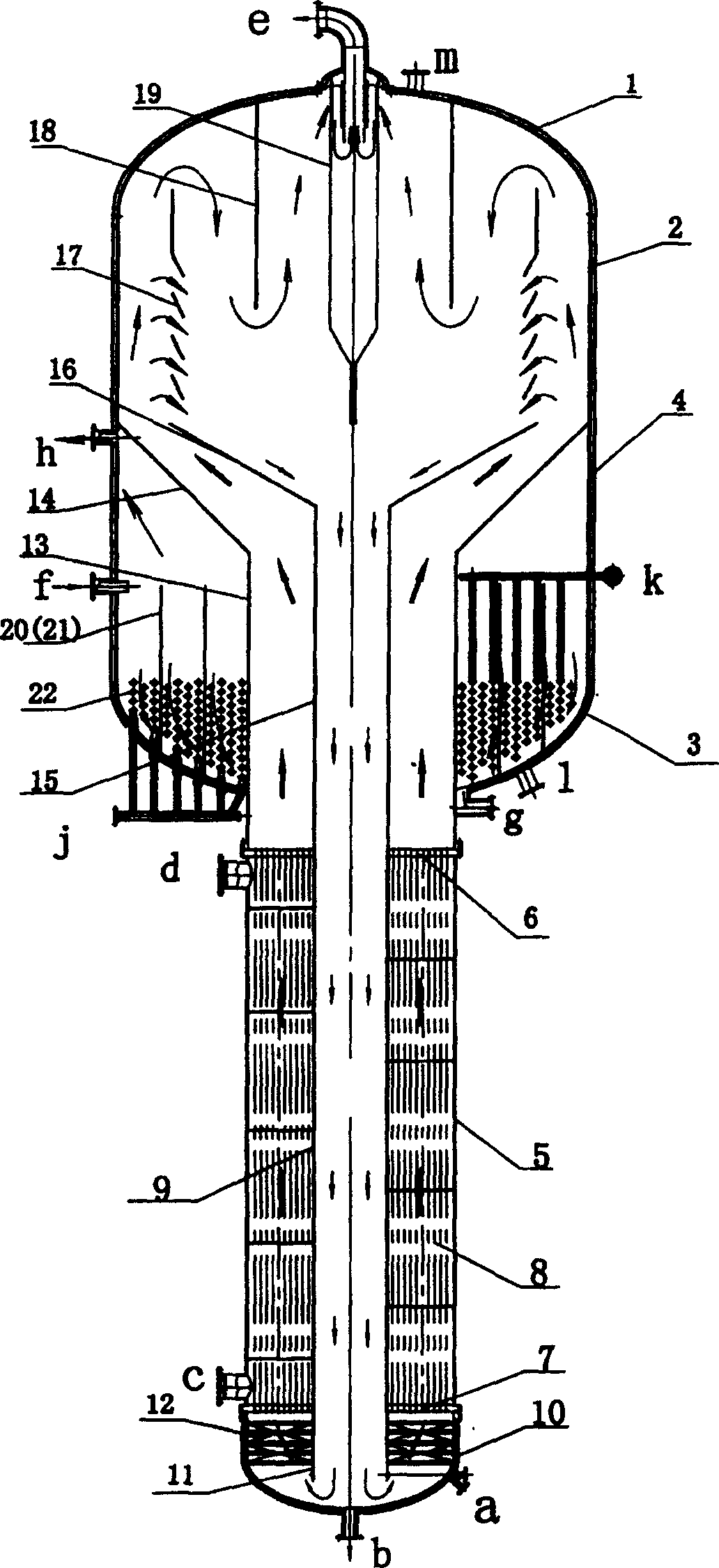

[0029] The present invention is further illustrated with the following specific embodiments in conjunction with the accompanying drawings, but the scope of protection is not limited to the following specific embodiments.

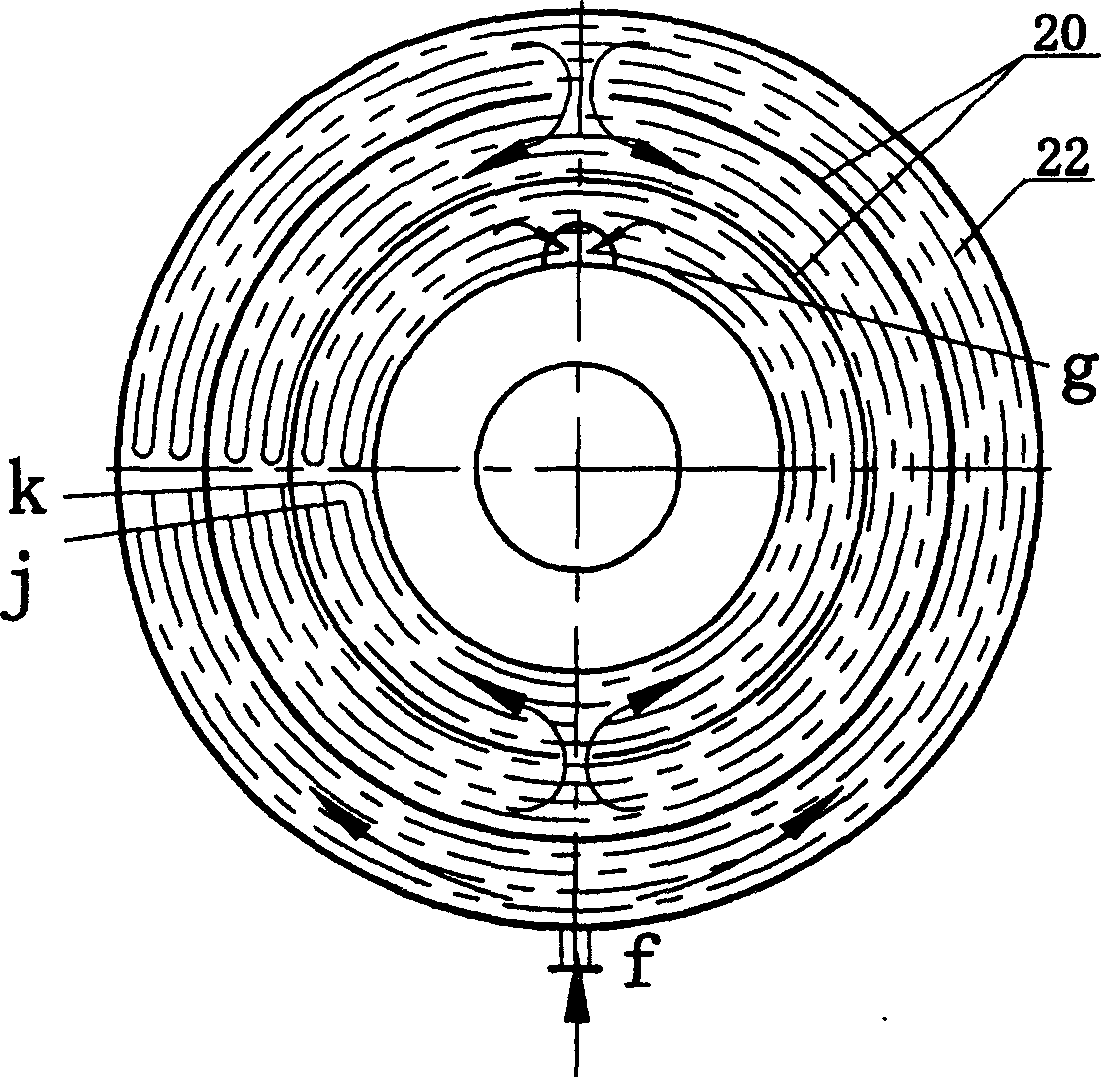

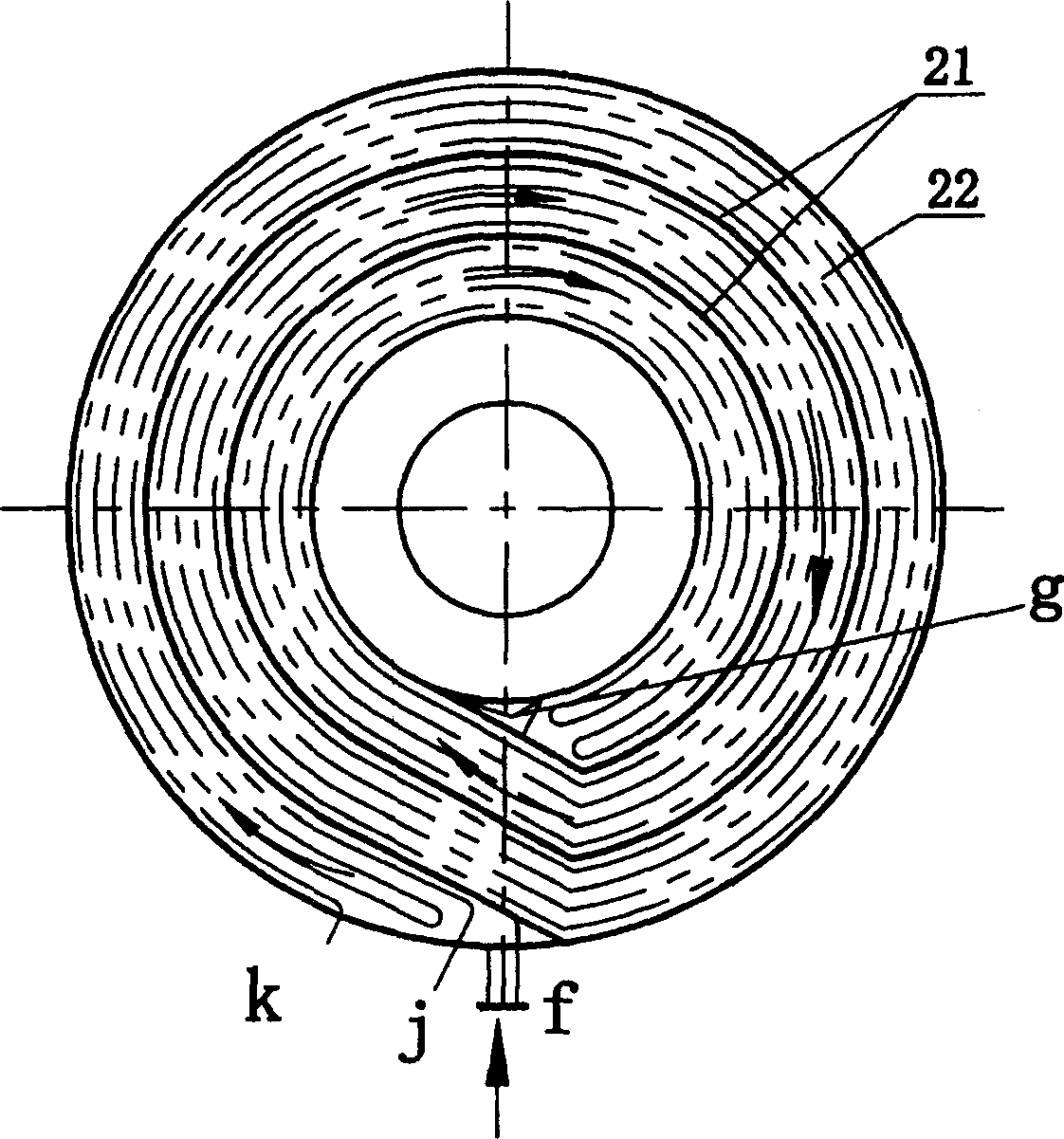

[0030] In the non-stirring dual-zone esterification kettle of the present invention, the slurry with a molar ratio of EG and TPA of 1.8 enters the lower part of the annular space between the small head 10 at the bottom of the first esterification zone and the inner pipe 11 through the nozzle from the slurry inlet a , merges with the esterified product that circulates back from the inner tube 11 of the small head at the bottom, flows upward after being mixed by the annular static mixer 12, and enters the heat exchange array tubes 8 through the annular lower tube plate 7 of the heat exchanger, and in the array tube The medium is heated by the shell-side heat medium to carry out esterification, the water generated by the reaction and the excess EG in the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com