A polyester waste heat utilization device

A waste heat, polyester technology, applied in the field of polyester chemical production, can solve the problems of affecting the esterification reaction, single utilization, large fluctuation of steam pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

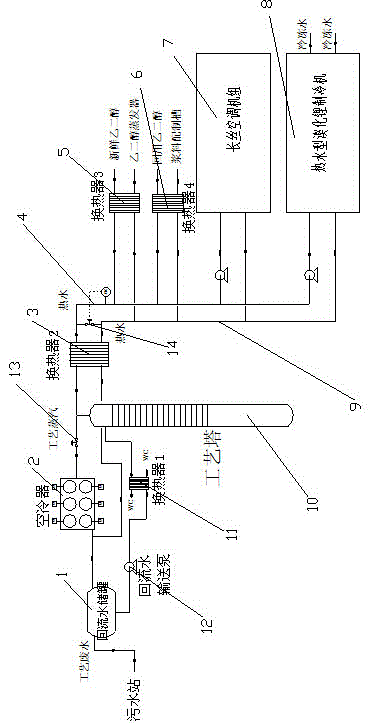

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, a polyester waste heat utilization device described in this embodiment includes a return water storage tank 1, a return water delivery pump 12, an air cooler 2, a process tower 10, a filament air conditioning unit 7, and a hot water lithium bromide refrigerator 8. Heat exchanger one 11, heat exchanger two 3, heat exchanger three 5, heat exchanger four 6, regulating valve 14, pneumatic valve 13, inlet water main pipe 4, return water main pipe 9; A three-way pipe, one end of the three-way pipe is connected with the air cooler 2, and a pneumatic valve 13 is installed between the process tower 10 and the air cooler 2, and the air pressure at the top of the process tower 10 is controlled by the pneumatic valve 13 to stabilize, and the other end of the three-way pipe One end is connected to the heat exchanger 2 3, the steam at the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com