Flow direction changing controller and backwash pre-filter

A pre-filter and fluid direction technology, which is applied to fixed filter elements, filter separation, separation methods, etc., can solve problems such as difficult cleaning and inconvenient cleaning of impurities, and achieve fast operation, saving installation, and thorough cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

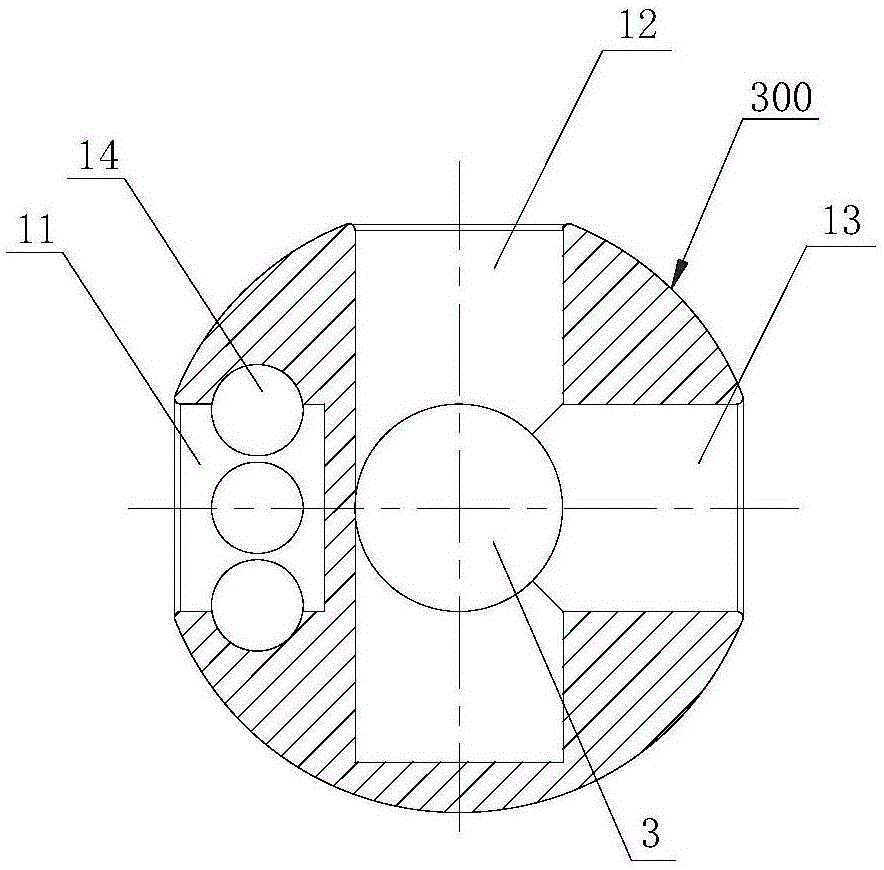

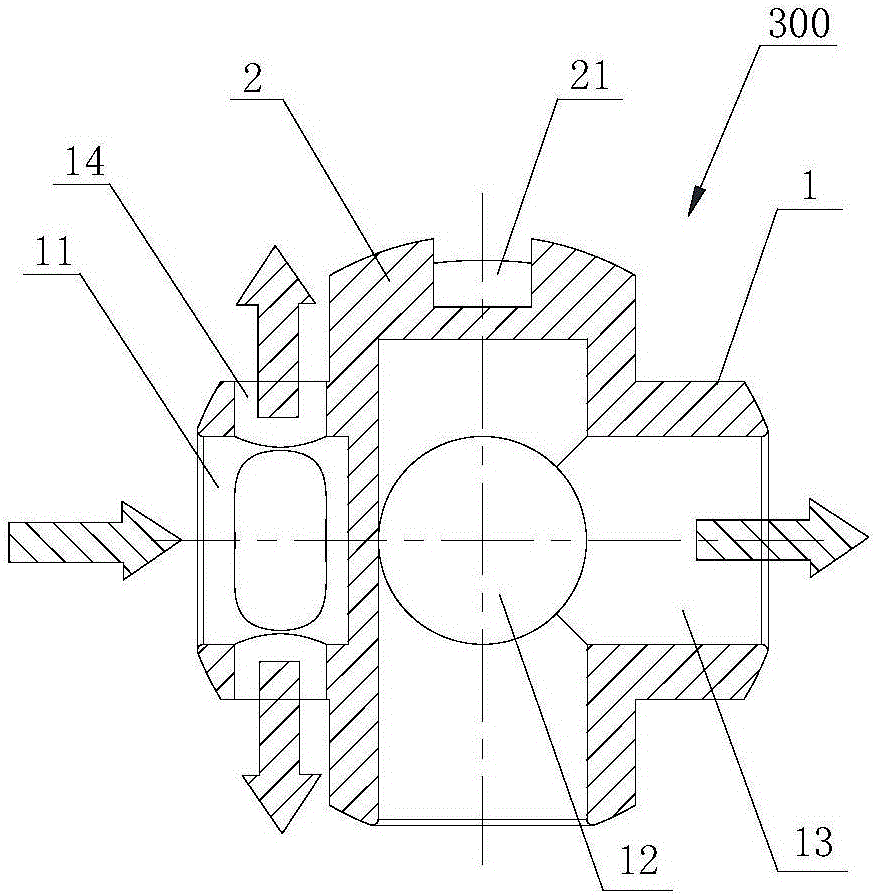

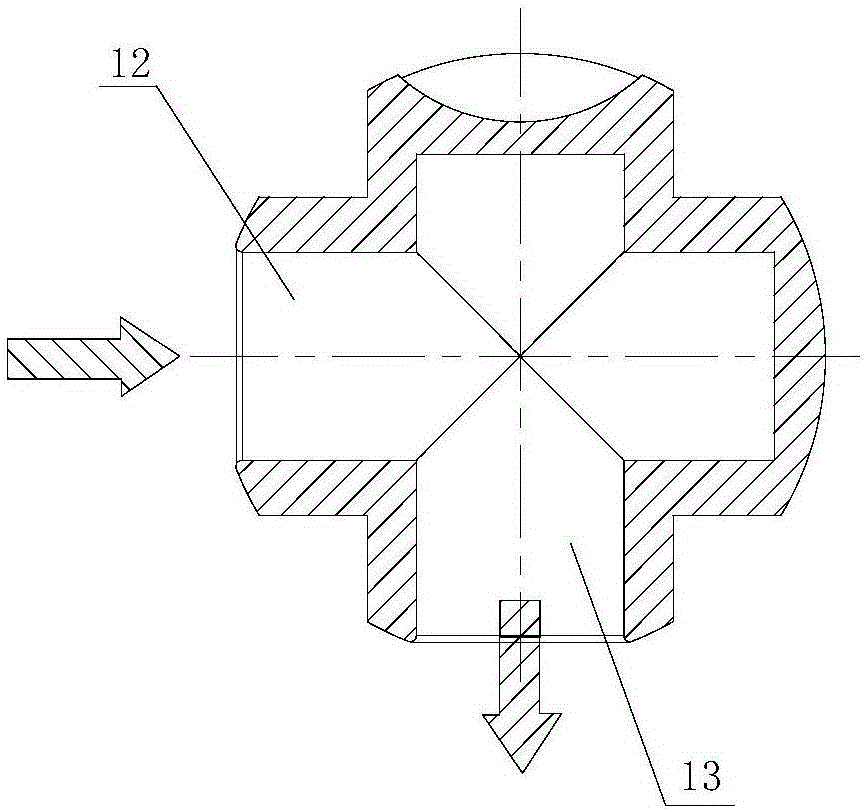

[0032] Such as Figure 1 to Figure 3 As shown, the fluid direction switching control 300 provided in this embodiment includes a control body 1 and a rotating member 2 . The control body 1 is spherical, and the side wall of the control body 1 has a first connection hole 11, a second connection hole 12, a third connection hole 13, and is formed on one side of the first connection hole 11 and communicates with the first connection hole 11 and the filter. At least one water outlet hole 14 outside the element 200, the first connection hole 11 and the second connection hole 12 are blocked by the control body 1, the first connection hole 11 and the third connection hole 13 are blocked by the control body 1, and the second connection hole 12 communicates with the third connection hole 13 through the inside of the control body 1 . The rotating member 2 is arranged on the upper part of the control body 1 and is connected with the external switch 400 to drive the control body 1 to rotat...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1 and its variations, except that the backwash pre-filter provided in this embodiment is a straight-through backwash pre-filter (that is, there is no universal joint in the filter body). The backwash pre-filter of this embodiment includes a filter body 100', a filter element 200', a fluid direction switching control 300', a switching switch 400' and a drain valve 500'. The filter body 100' has a water inlet 101' and a water outlet 102'. The filter element 200' is disposed in the filter body 100'. The fluid direction conversion control 300' is arranged in the filter body 100' and connected with the filter element 200', so that water flows through the filter element 200' in opposite directions in the filtering state and the backwashing state. The changeover switch 400' is connected with the rotary groove 21' in the fluid direction changeover control 300'. The drain valve 500' is connected with the filter element 200'. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com