A punch transport manipulator

A technology for manipulators and materials transportation, which is applied in the direction of manipulators, program-controlled manipulators, and metal processing equipment. It can solve the problems of not being able to meet the needs of large-scale CNC punching machines, not being able to afford punching materials, and the impact on transportation efficiency, so as to achieve efficient automatic operation of loading and unloading, and improve Good work efficiency and delivery accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

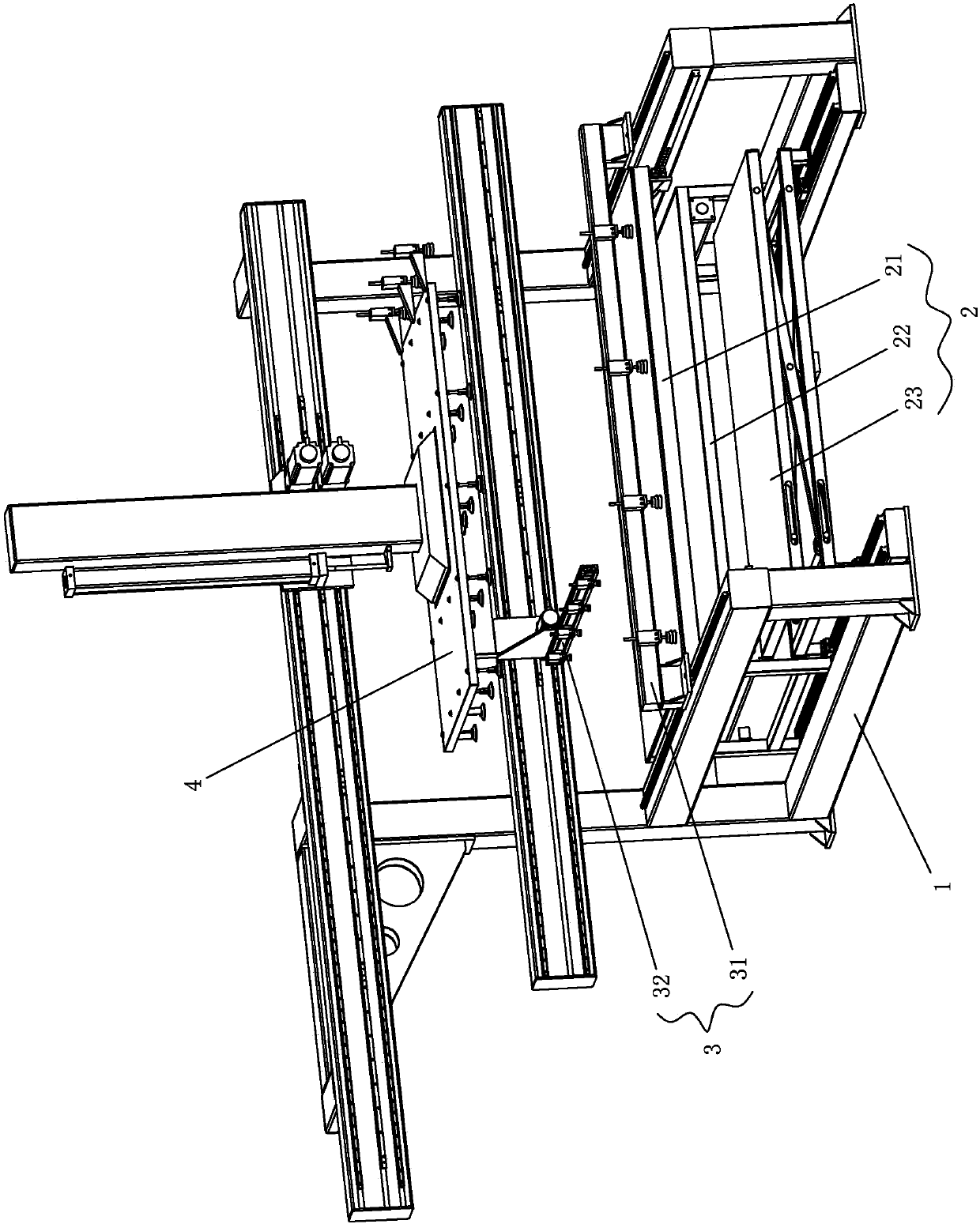

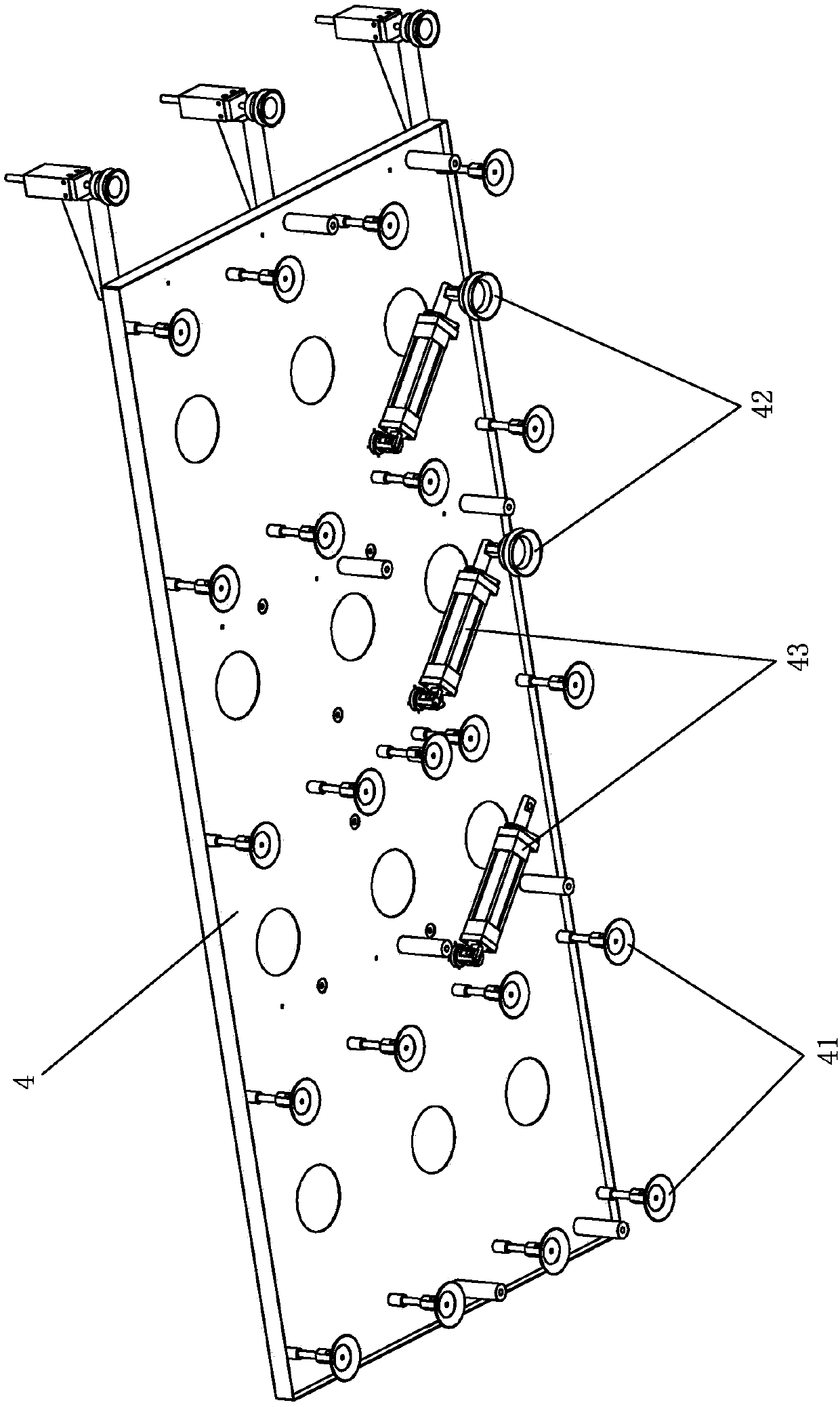

[0017] refer to figure 1 and figure 2 , a punch transport manipulator of the present invention, comprising a frame 1, the lower part of the frame 1 is provided with a horizontally movable material transport mechanism 2, and the frame 1 is respectively provided with horizontally movable The material shifting mechanism 3, and the lifting and transporting mechanism 4 that can vertically lift and move horizontally, the lower side of the lifting and transporting mechanism 4 are provided with several lifting suction cups 41 and several movable positioning suction cups 42.

[0018] The material transport mechanism 2 includes an upper material rack 21, a middle material rack 22, and a lower material rack 23 that can move horizontally and vertically from top to bottom, and the lower material rack 23 can be lifted up and down, and the material shifter 23 can move up and down. Mechanism 3 includes a vertically moving material rod 31 that moves horizontally and vertically, and a horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com