Forming die of thermoplastic ship body

A thermoplastic, hull technology, applied in the coating and other directions, can solve the problems of worker injury, waste of raw materials, leakage, etc., to achieve the effect of simple structure and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

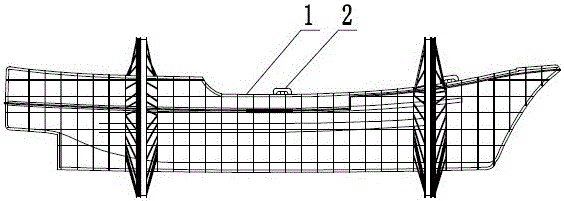

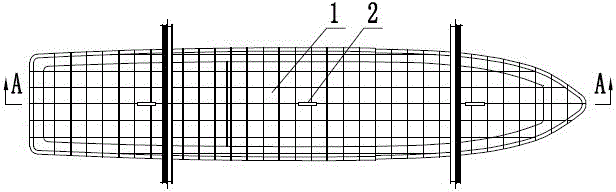

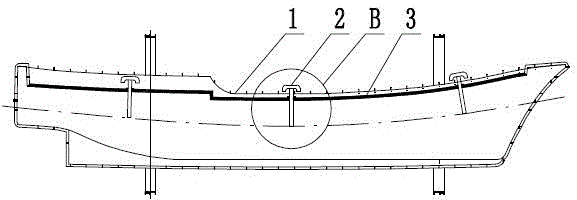

[0021] In the example, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a molding abrasive tool for a thermoplastic hull includes a vent pipe 2 arranged on a mold 1, and the vent pipe 1 includes an insertion section 21 inserted inside the mold 1 and a leak-proof section 22 arranged outside the mold 1; The insertion section 21 communicates with the leakage prevention section 22 , the insertion section 21 is perpendicular to the rotation axis of the mold 1 , and the leakage prevention section 22 is parallel to the rotation axis of the mold 1 . When the vent pipe 2 of this embodiment is rolling in the mold 1, the leak-proof section 22 can effectively prevent the material in the mold 1 from leaking out, reducing waste, and will not affect the normal exhaust of the mold 1; the whole structure is also very simple , compared with the normal sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com