Automobile seat sliding rail

A technology for car seat slide rails and slide rails, applied in vehicle seats, movable seats, vehicle parts, etc., can solve the problems of affecting the driving safety of drivers, uneven force, large resistance, etc., and achieve uniform force. , Improve the anti-extrusion ability and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

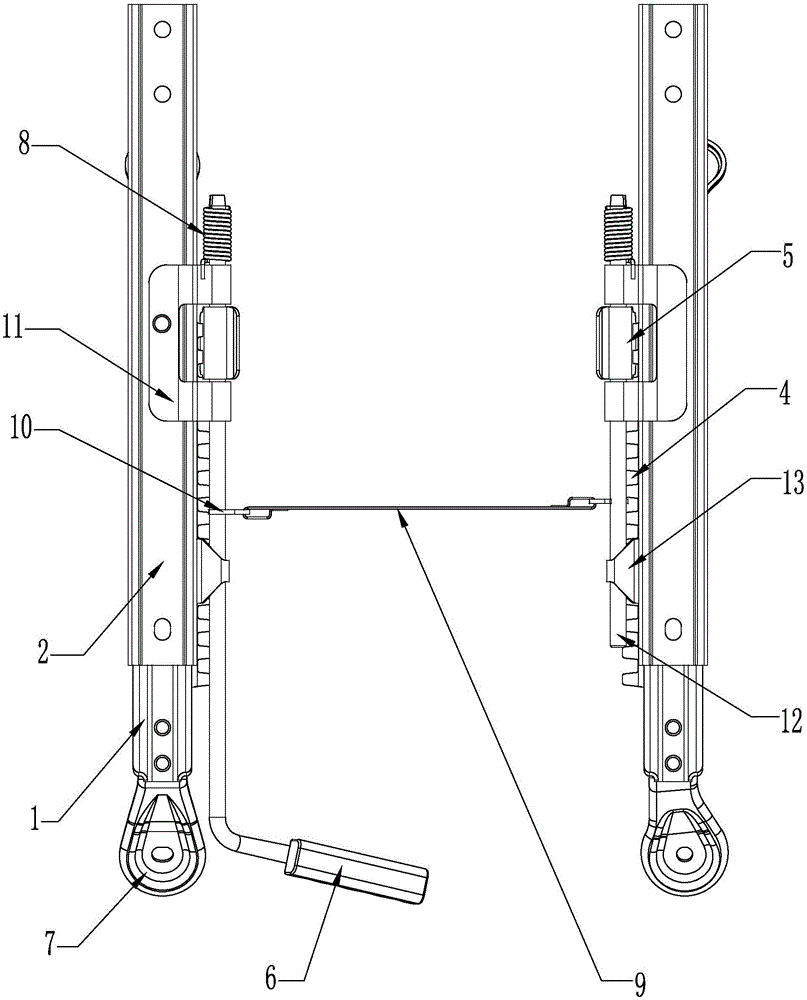

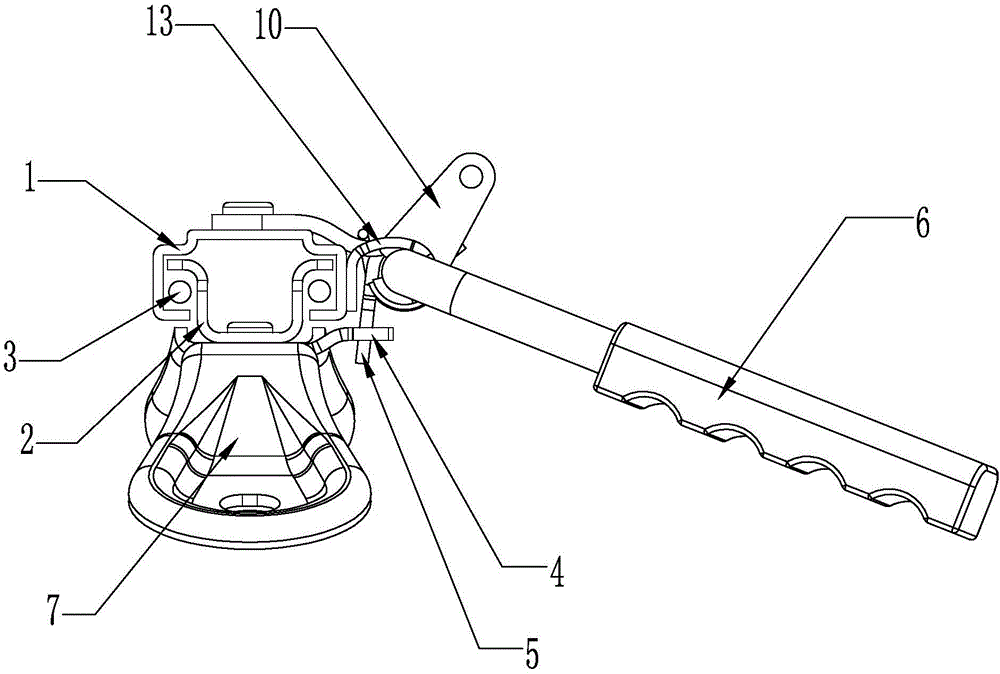

[0010] like figure 1 figure 2 As shown, the car seat slide rail includes the lower fixed rail fixed plate 7 fixed on the car body and the lower fixed rail 1 fixed on the lower fixed rail fixed plate 7, and the lower fixed rail fixed plate 7 is composed of left and right two parts, Each lower fixed track fixing plate 7 is respectively provided with a lower fixed track 1, and the upper sliding track 2 is respectively sleeved on the lower fixed track 1 on both sides. The upper sliding track 2 and the lower fixed track 1 both sides form a ball cavity, and the balls A plurality of balls 3 are provided in the cavity, and a limit cogging return fixing plate 11 is respectively provided on the opposite side of each upper sliding track 2, and each limit cogging return fixing plate 11 is respectively provided with a Cogging return fixed plate 11 parallel rotating rod 12, the rotating rod 12 of each side runs through the rotating rod fixing seat 13 of each side respectively, and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com