Bulk grain transporting vehicle carriage with forcible ventilation and natural ventilation functions

A natural ventilation and forced ventilation technology, applied in the field of transport vehicles, can solve problems such as poor economic benefits, high transportation costs, and air inability to circulate, and achieve high practicality and good economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

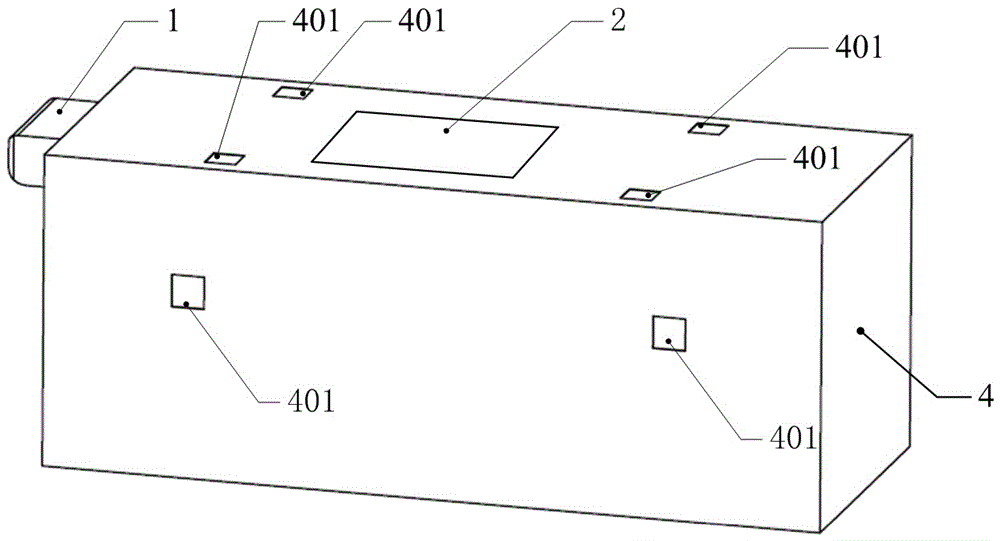

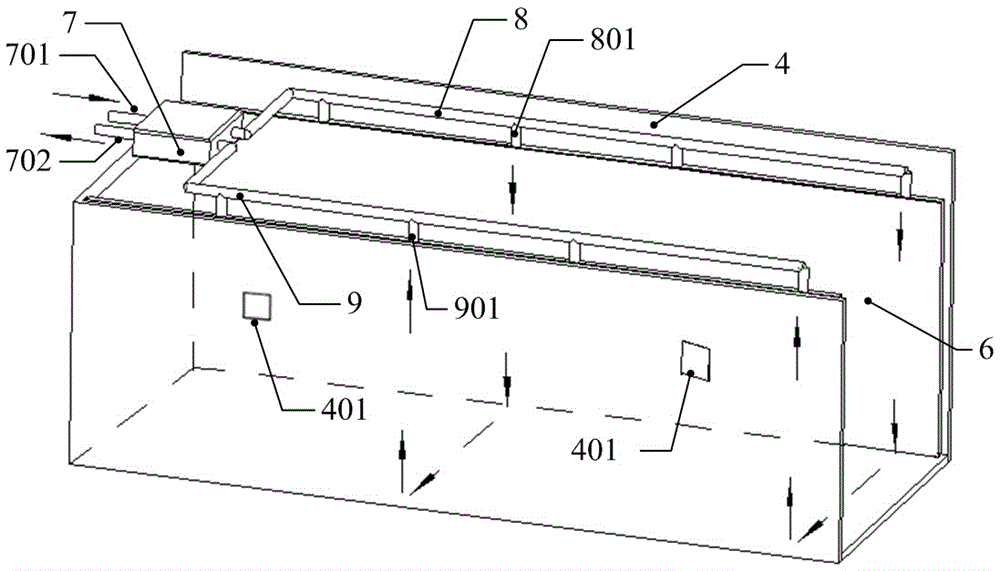

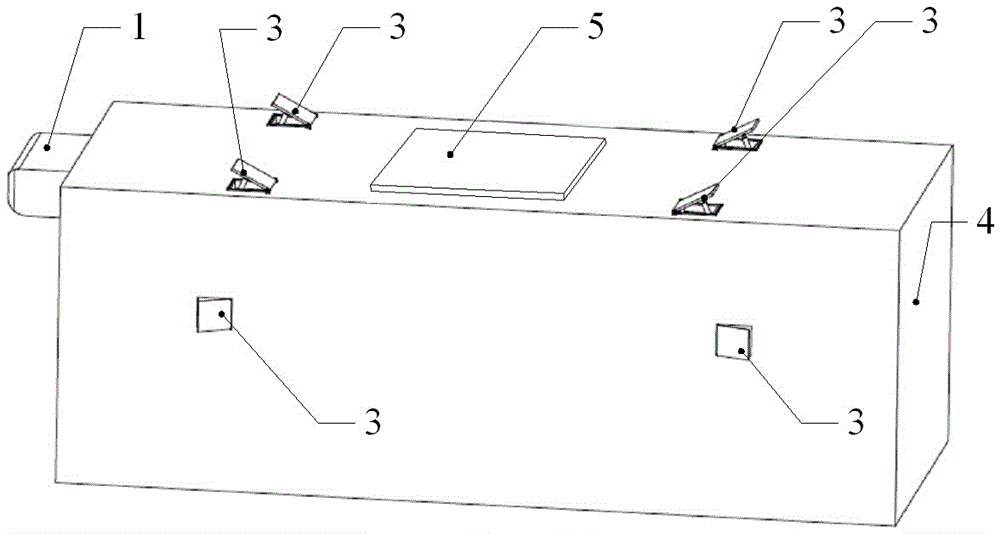

[0030] see figure 1 , figure 2 , image 3 A compartment of a bulk grain transport vehicle with forced ventilation and natural ventilation, comprising a windshield assembly 3 , an outer compartment 4 , an inner compartment 6 , and a heat exchanger 7 . The outer box body 4 is in the shape of a closed cuboid box and is composed of a top wall, a left side wall, a right side wall, a bottom wall, a front end wall and a rear end wall. The board, the right side wall, the bottom wall, the front wall and the rear wall are all insulation boards. The insulation board is composed of two layers of thin steel plates filled with polyurethane material. The thickness of the thin steel plate is 1.5mm, and the thickness of the polyurethane material is 45mm. .

[0031] The central part of the top wall plate has a rectangular grain loading port 2, and a cover plate 5 is provided on the grain loading port 2. There are 4 vents 401 on the top wall, of which 2 vents 401 are located at the front of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com