A device for manually arranging the flat tubes in the warehouse on the tooth seat

A material storage and gear seat technology, which is applied in the field of devices for manually arranging flat tubes in the material storage on the tooth base, can solve problems such as irregular arrangement of flat tubes, affect work progress, and low work efficiency, and achieve easy maintenance and repair , improve efficiency, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

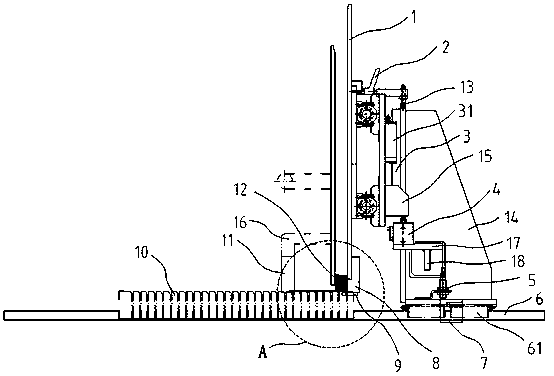

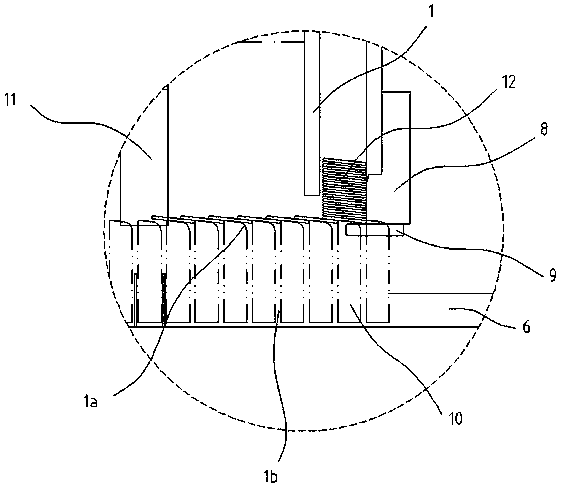

[0022] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach figure 2 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0023] figure 1 It is a structural diagram of an embodiment of a device for manually arranging the flat tubes in the silo on the gear seat of the present invention; figure 2 for figure 1 Enlarged view of the part corresponding to the middle letter A. Such as figure 1 and figure 2 As shown, the device for manually arranging the flat tubes in the silo on the gear seat provided by this embodiment includes: the first guide rail 6, the first slider 61, the segment replacement block 7, the sensor 5, the first mounting seat 14, the first Second guide rail 3, second slider 31, second mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com