Anti-lifting safety device for rear plate of escalator

A technology of safety device and rear panel, which is applied in escalators, transportation and packaging, etc., can solve problems such as not meeting the requirements of the new national standard, achieve the effects of preventing accidents, improving reaction speed, and facilitating installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

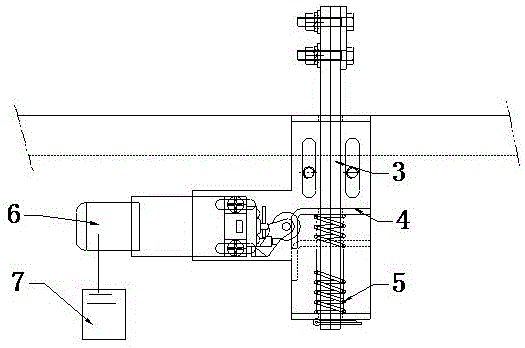

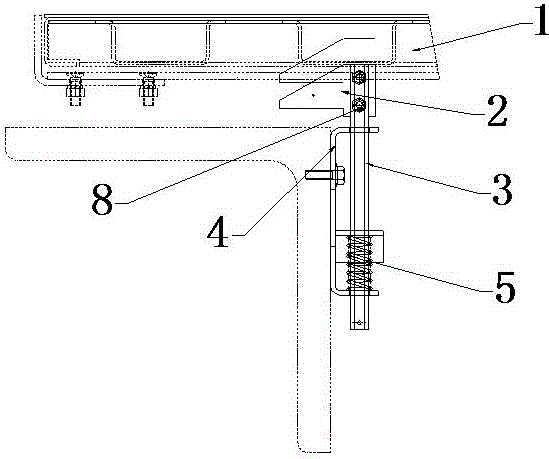

[0011] Such as figure 1 and figure 2 Shown: an escalator rear plate anti-lifting safety device related to the present invention, including a rear plate, a baffle plate 2 is arranged under the rear plate 1, a guide rod 3 is fixedly connected to the baffle plate 2, and the middle end of the guide rod 3 is clamped Connect a pressing plate 4, below the pressing plate 4, there is a pop-up baffle plate 2 and a spring assembly 5 of the pressing plate 4 that are sleeved on the guide bar 3, and a safety switch 6 is mechanically connected to the side of the pressing plate 4, and the safety switch 6 is directly connected to the control power supply 7 of the escalator. The spring assembly 5 is in a compressed state when the back plate 1 is covered, and is in an open state when the back plate 1 is lifted. The elasticity of the spring can be utilized to control the safety switch 6 to ensure safety. The pressure plate 4 and the guide rod 3 are fixedly connected by the fixing bolt 8, which ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap