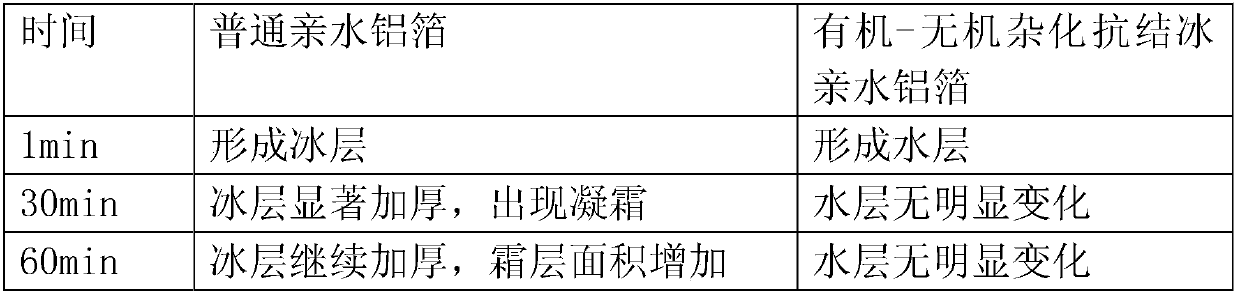

Organic-inorganic hybrid anti-icing hydrophilic aluminum foil coating

A hydrophilic aluminum foil, anti-icing technology, applied in the direction of coating, can solve problems such as no effective solutions, and achieve the effect of satisfying anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with embodiments.

[0029] 1. Preparation of inorganic nanoparticles

[0030] Prepare methanol and water as a solvent in a mass ratio of 1:2, and mix tetraethoxysilane and the solvent in a constant temperature water bath at 40-90°C in a mass ratio of 1:2. After fully stirring, add the hydrochloric acid catalyst dropwise in 30 minutes. After 2 hours of heat preservation, the nano-sol was obtained.

[0031] 2. Preparation of water-based acrylic resin

[0032] Make acrylic acid, acrylamide and water into a monomer solution in a constant temperature water bath at 50-90°C in a mass ratio of 1:4.5. After fully stirring, add the ammonium persulfate solution dropwise for 2 hours, then raise the temperature by 2°C, and keep it for 1 hour. That is, a water-based acrylic resin was obtained.

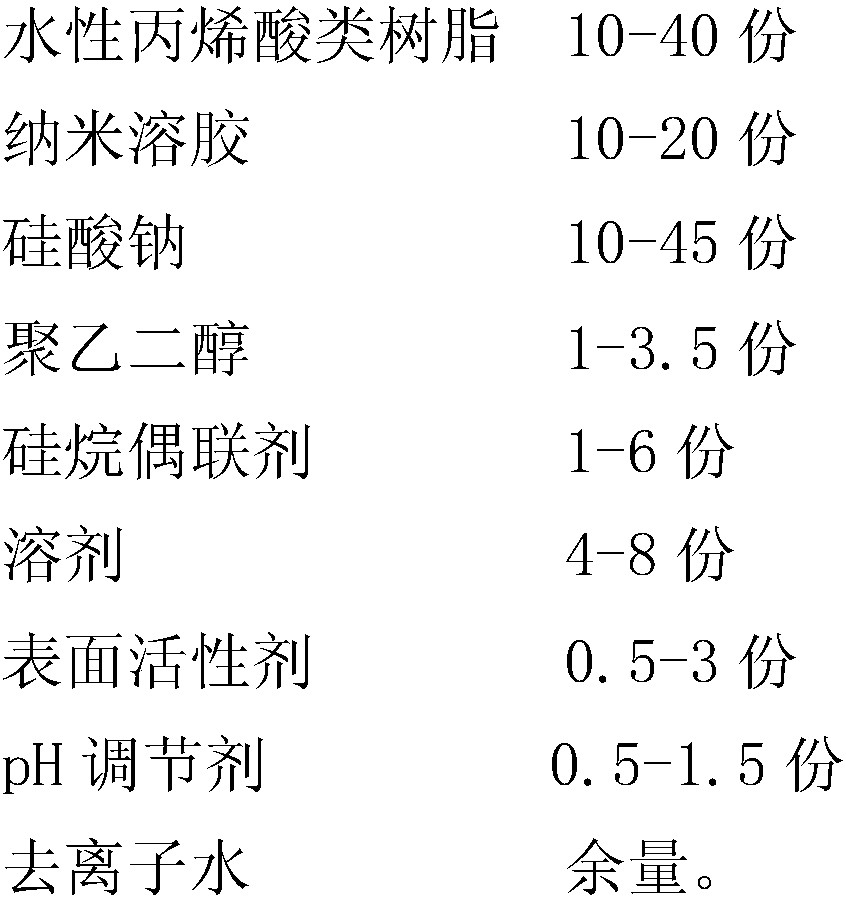

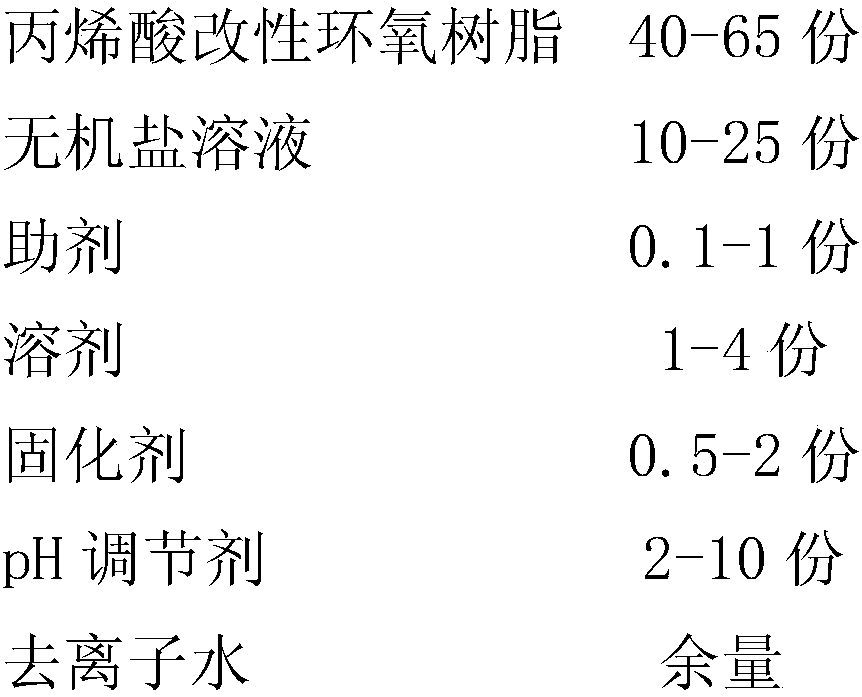

[0033] 3. Preparation of organic-inorganic hybrid anti-icing hydrophilic surface coating

[0034] Basic formula (parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com