Preparation method of super-hydrophilic self-cleaning coating based on cation-pi effect

A self-cleaning coating, cationic technology, applied in the field of super-hydrophilic materials, can solve the problems of large molecular radius of cationic polymers, cumbersome preparation process of modified separation membrane, thick hydration layer, etc. Cleaning performance, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a superhydrophilic self-cleaning coating based on cation-π interaction, comprising steps:

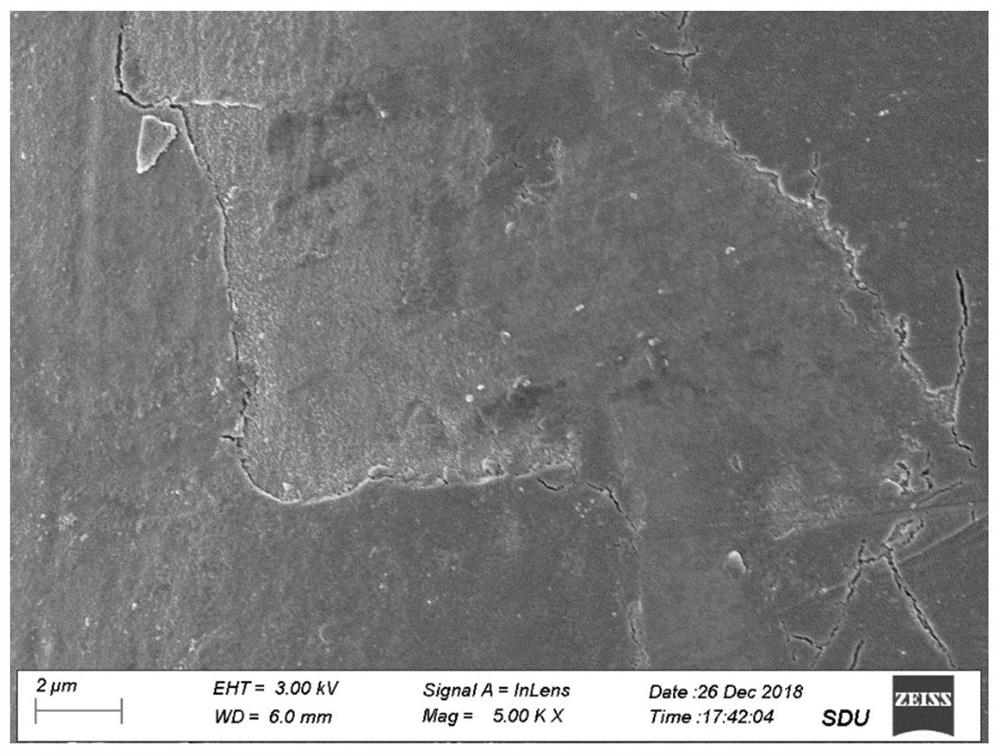

[0038] Dissolve 2g of tannic acid (TA) in 40mL of aqueous sodium hydroxide solution (pH is 8) to form a polyphenol alkaline solution; then add 5g NaCl to the polyphenol alkaline solution, mix and dissolve to obtain a stock solution; Next, the base copper mesh (200 mesh) was immersed in the stock solution, soaked for 48 hours under stirring, and then washed with distilled water and dried to prepare a coated modified copper mesh, that is, a TA-Na modified copper mesh.

Embodiment 2

[0040] A method for preparing a superhydrophilic self-cleaning coating based on cation-π interaction, comprising steps:

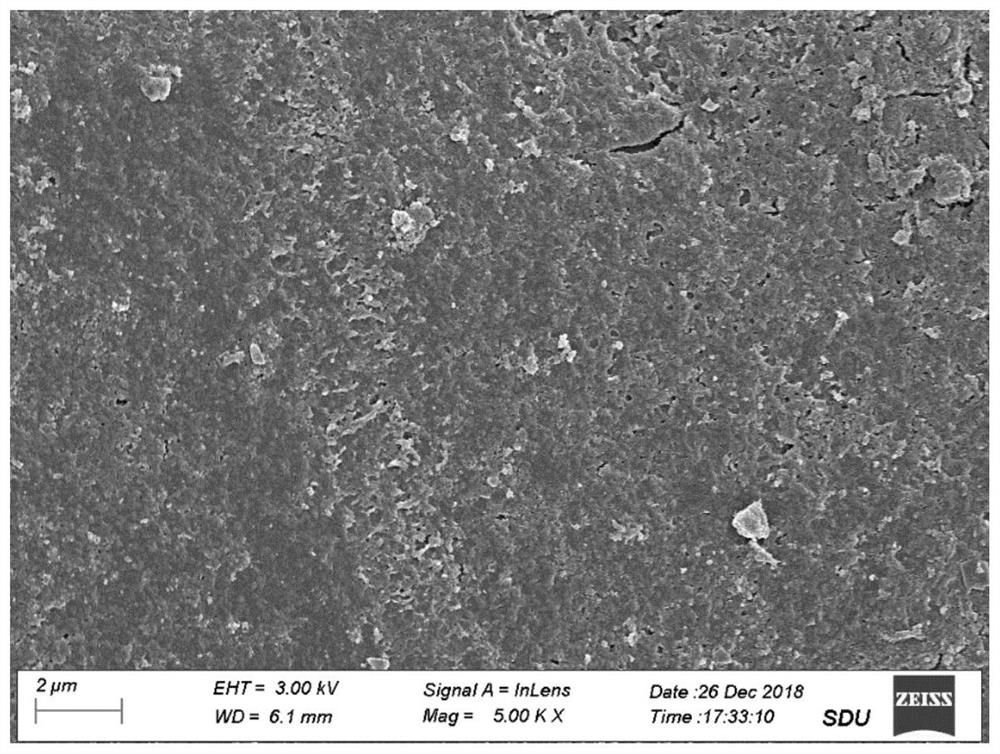

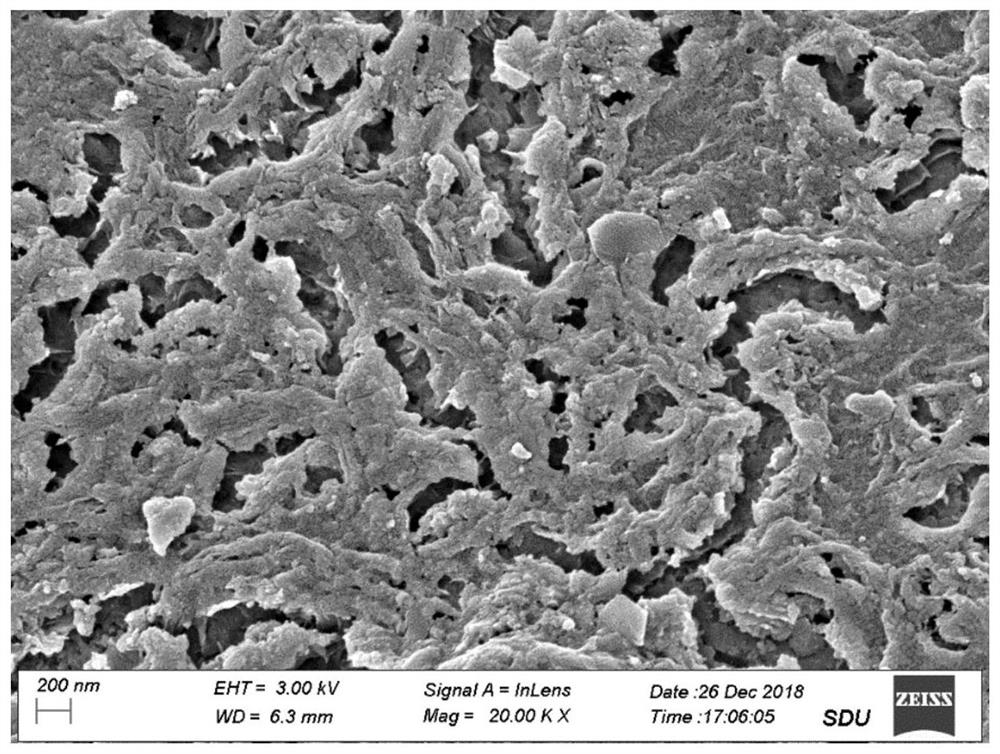

[0041] Dissolve 1 g of tannic acid (TA) into 40 mL of aqueous sodium hydroxide solution (pH 8) to form a polyphenol alkaline solution; then add 5 g of tetramethylammonium chloride to the polyphenol alkaline solution, mix and dissolve The stock solution was obtained; then the base copper mesh (200 mesh) was immersed in the stock solution, soaked for 24 hours under stirring conditions, and then washed with distilled water and dried to prepare a coated modified copper mesh, that is, a TA-TMA modified copper mesh.

Embodiment 3

[0043] A kind of preparation method of superhydrophilic self-cleaning coating based on cation-π effect, as described in embodiment 2, the difference is: the substrate is replaced by glasses, and only one side of the glasses is coated, other steps And the conditions are consistent with Example 2, and TA-TMA modified glasses are prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com