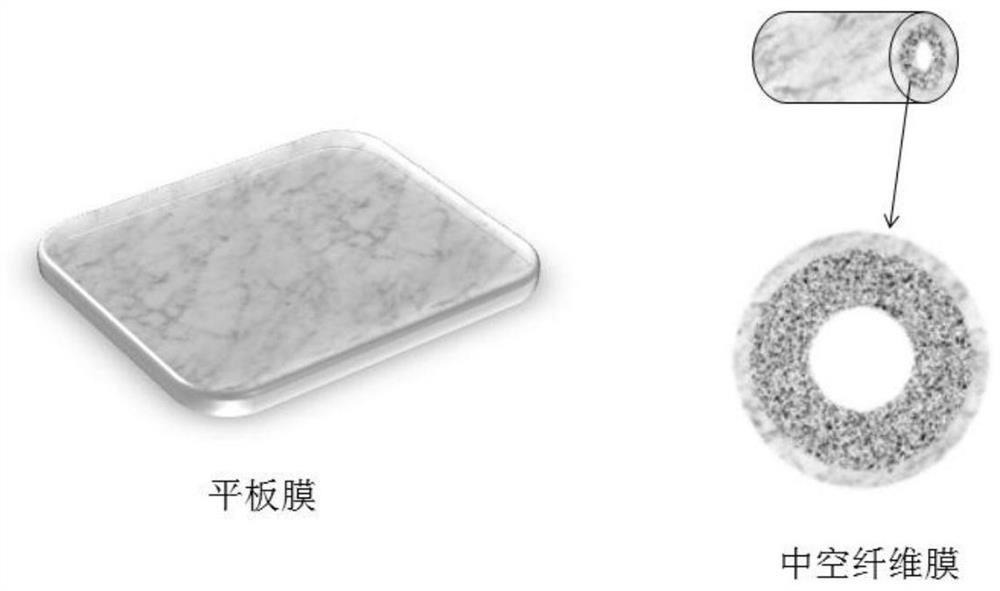

Chitosan-based composite membrane and preparation method thereof

A technology of chitosan and composite membrane, which is applied in the field of membrane materials to achieve the effect of high super-hydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

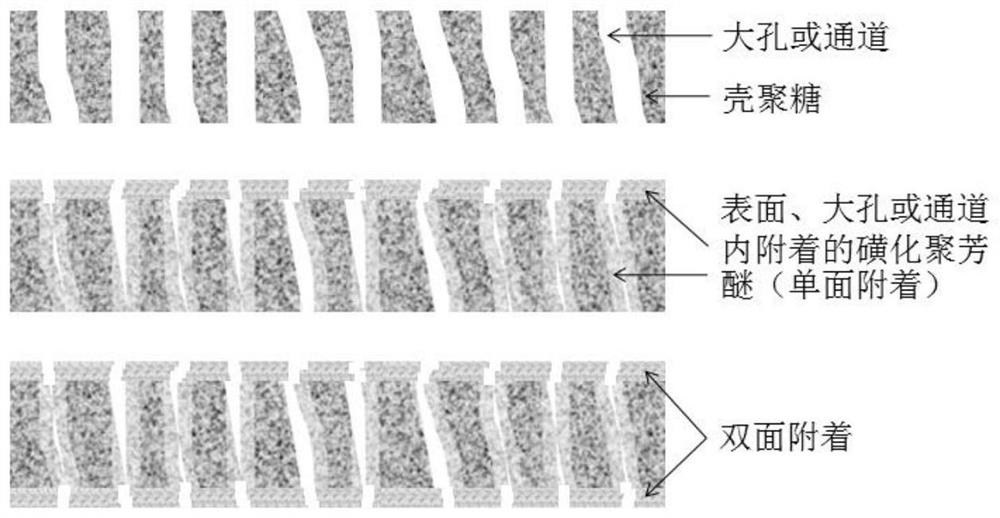

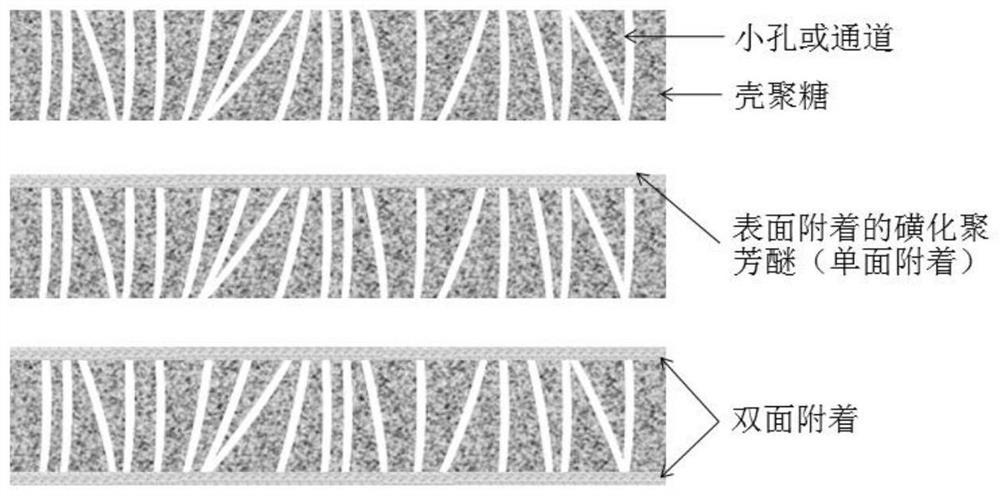

[0084] In some embodiments, the preparation method of the composite membrane with alternate double-sided adhesion of the sulfonated polyarylether and chitosan layers comprises: immersing the chitosan-based membrane in an aprotic polar solvent used to dissolve the sulfonated polyarylether. solvent, repeated 3 times, and then immersed in the sulfonated polyarylether solution for 2 hours. The membrane was taken out, immersed in the same solvent, repeated 3 times, then immersed in deionized water, repeated 3 times, and then immersed in the chitosan-based membrane solution for 2 hours. Then immerse in deionized water and alkaline aqueous solution in turn, and then soak in deionized water for 3 times. Repeat the above operations to obtain a double-sided multilayer adhesive composite film. Wherein, the chitosan-based membrane solution includes a solution obtained by mixing chitosan, an acid such as acetic acid, a volatile agent such as 95% ethanol, a porogen such as PEG400, and wate...

Synthetic example 1

[0114] Synthesis Example 1-Synthesis Example 7

[0115] Preparation of sulfonated polyphenylsulfone (salt form):

[0116]

[0117] Take the preparation of sulfonated polyphenylsulfone with 20% sulfonation degree as an example: before starting the reaction, the raw materials are pretreated, DCDPS and BP are dried in a vacuum oven at 55°C for 12h, K 2 CO 3 , SDCDPS was dried in a vacuum oven at 120°C for 12 hours. Under nitrogen (99.999%, flow rate: 10-15) atmosphere, 9.82g bis(4-chloro-3-sulfonated phenyl)sulfone (SDCDPS), 22.97g4,4'-dichlorodiphenylsulfone (DCDPS) and 18.62 g biphenol (BP) was added to a 500mL straight three-necked flask equipped with a water separator, a serpentine condenser, an elbow, a stirring paddle and an air duct, and then 128mL N,N-dimethylacetamide (DMAc ), 64mL toluene (Tol), 15.89g anhydrous potassium carbonate were added thereto. DMAc is used as a solvent, anhydrous potassium carbonate is used as an acid-binding agent, and toluene is used as...

Synthetic example 8

[0123] Synthesis Example 8-Synthesis Example 27

[0124] Preparation of chitosan-based membrane:

[0125] According to a certain ratio (see Table 3 for details), 95% ethanol, acid acetic acid, water, porogen PEG400 and chitosan (95% degree of deacetylation) of different qualities are mixed, stirred for a certain period of time (see Table 3 for details), and obtained Chitosan-based membrane solution, that is, casting solution. The solution was left to defoam in an ultrasonic instrument for one hour, and the drying platform was calibrated horizontally in advance, and a certain volume of casting solution (see Table 3 for details) was weighed and poured on a clean glass plate (10×10cm), so that It expands to the same size as the carrier. Then dry in an infrared light box at 80°C for 24 hours, until all the solvents are completely evaporated; then immerse the film in a 10% sodium hydroxide solution for 1 hour, then transfer to distilled water for immersion, and wait until the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ion exchange capacity | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com