A waterproof structure and construction method for bolt hole of shield tunnel segment

A tunnel segment and construction method technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as insufficient stability and durability, loss of water-absorbing materials, quality loss, and decline in physical properties, and achieve good durability , Improve the effect of waterproof pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

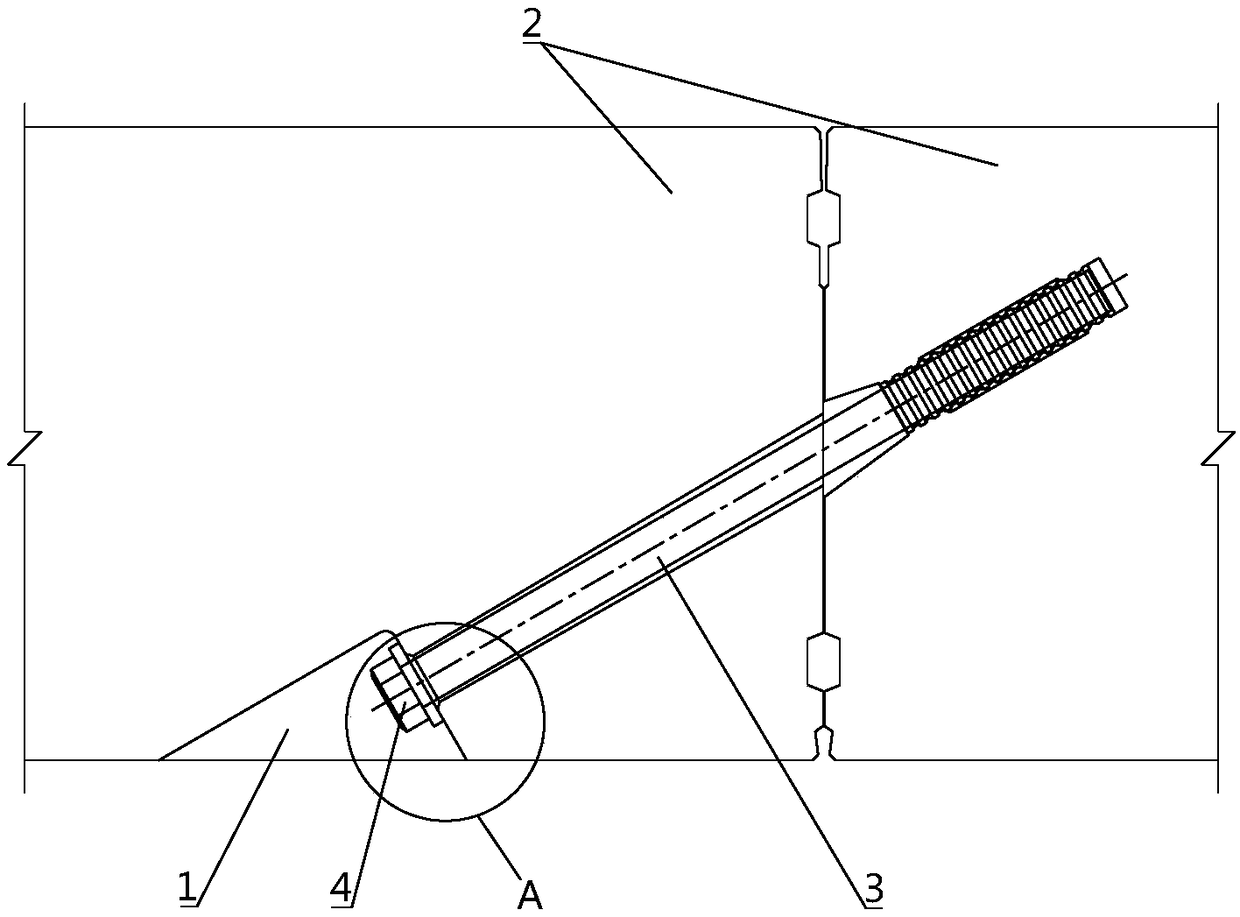

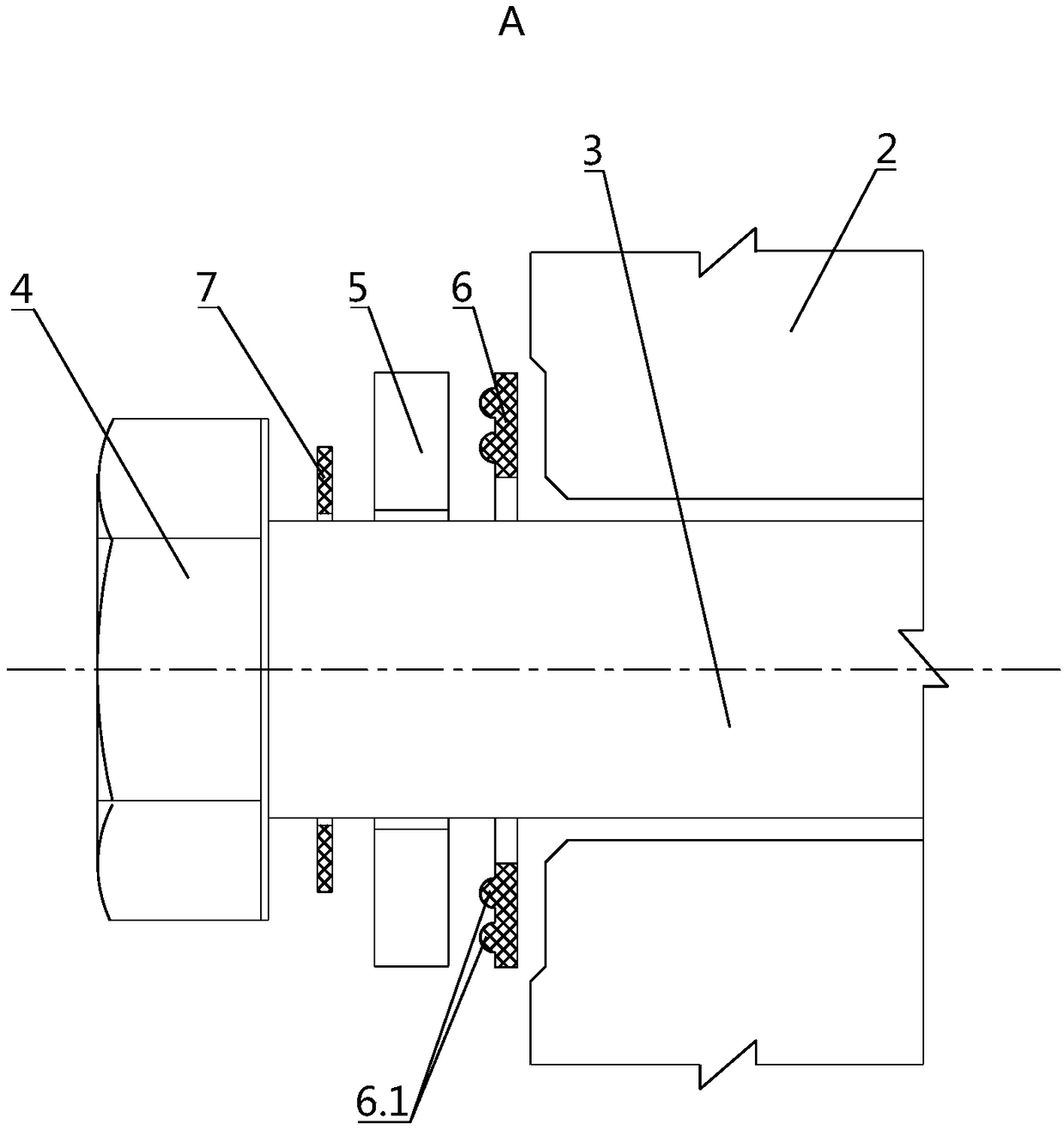

[0025] pass below Figure 1 to Figure 4 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

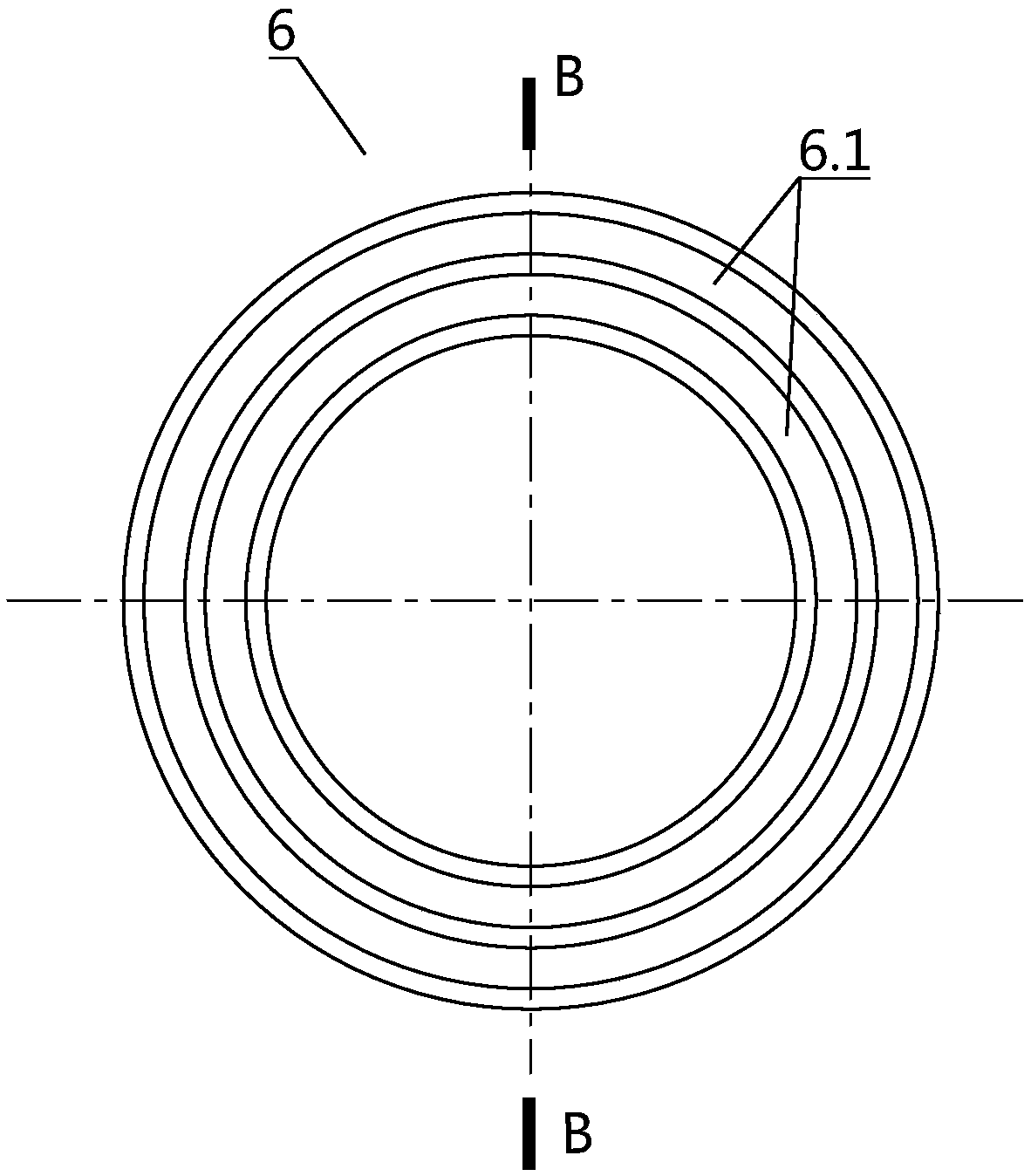

[0026] Such as figure 1 and figure 2 As shown, the shield tunnel segment bolt hole waterproof structure designed by the invention includes the bolt 3 connecting the segment 2 in the bolt hole 1, the bolt washer 5 between the bolt head 4 of the bolt 3 and the segment 2, and the The first waterproof gasket 6 between the bolt washer 5 and the segment 2, the second waterproof gasket 7 between the bolt head 4 and the bolt washer 5; the side of the first waterproof gasket 6 in contact with the segment 2 is Plane, the side in contact with the bolt washer 5 is provided with at least one ring of semicircular p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com