Improved heating device connected between oil pipelines

A technology for oil pipelines and heating devices, which is applied to pipeline systems, pipeline protection, and pipeline protection through heat insulation. It can solve problems such as energy waste, insufficient heating, and heating channels that cannot be changed, so as to improve utilization efficiency and heating effect. , The effect of shortening the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

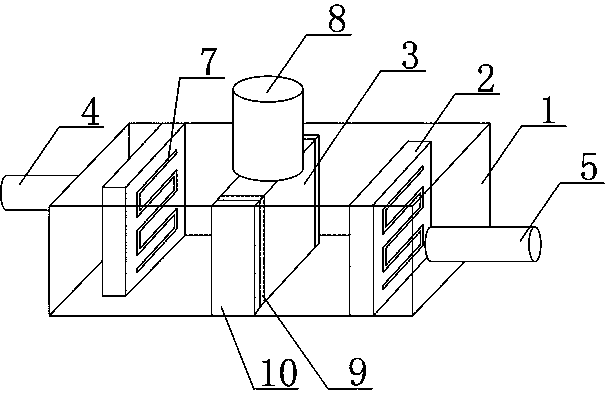

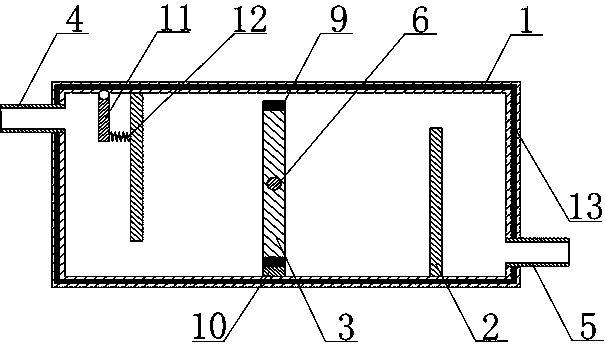

[0027] Such as figure 1 and figure 2 As shown in the figure, the present invention is an improved heating device connected between oil pipelines, including a casing 1, an oil inlet 4 and an oil discharge port 5 are respectively arranged on the sides of the casing 1 parallel to each other, and the inner wall of the casing 1 is fixed with Two fixed baffles 2, the fixed baffles 2 are parallel to the side where the oil inlet 4 is located, the top surface, bottom surface and one side of the fixed baffle 2 are connected with the shell 1, and the remaining three sides of the fixed baffle 2 are the same as the shell The inner wall, inner top surface, and inner bottom surface of 1 form a flow channel, and a resistance heating wire 7 is arranged on the fixed baffle 2, and a fixed baffle parallel to the fixed baffle 2 and the oil inlet 4 near the oil inlet 4 is provided. The unloading plate 11 of the plate 2, the side hinge of the unloading plate 11 is connected on the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com