Variable channel heating system for petroleum transportation

A channel-type, variable technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as energy waste, insufficient heating, and inability to change heating channels, to improve heating effect, improve Heating effect, effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

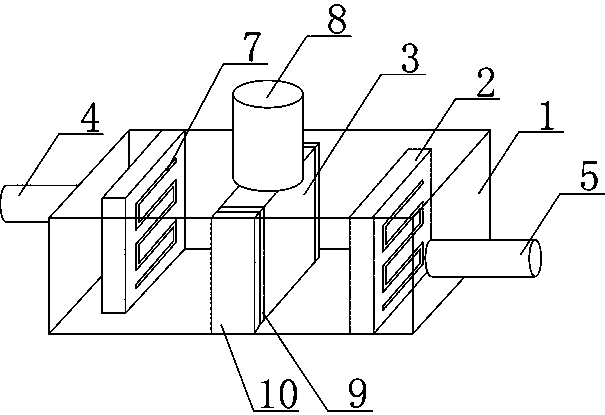

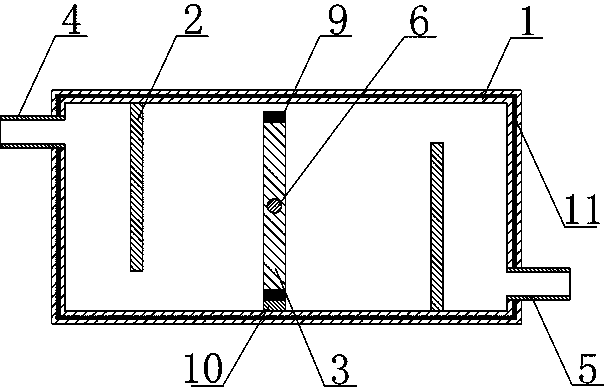

[0024] like figure 1 and figure 2 As shown in , the present invention is a variable channel type heating system for petroleum transportation, comprising a casing 1, an oil inlet 4 and an oil discharge 5 are respectively arranged on the sides of the casing 1 that are parallel to each other, and the casing is fixed on the inner wall of 1. There are two fixed baffles 2, the fixed baffles 2 are parallel to the side where the oil inlet 4 is located, the top surface, bottom surface and one side of the fixed baffle 2 are connected with the shell 1, and the other three sides of the fixed baffle 2 are the same The inner wall, the inner top surface, and the inner bottom surface of the shell 1 form a flow channel, and the fixed baffles 2 are provided with resistance heating wires 7, and the rotating baffles 3 parallel to the fixed baffles 2 are arranged between the fixed baffles 2. The top surface and the bottom surface of the baffle plate 3 are in contact with the inner top surface an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com