Equipment used for air sac test

A technology of airbags and equipment, which is applied in fluid tightness testing, material strength testing using stable tension/pressure, testing of machine/structural components, etc. It can solve the problems of inability to measure at the same time, cumbersome operation, and inability to ensure user safety, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

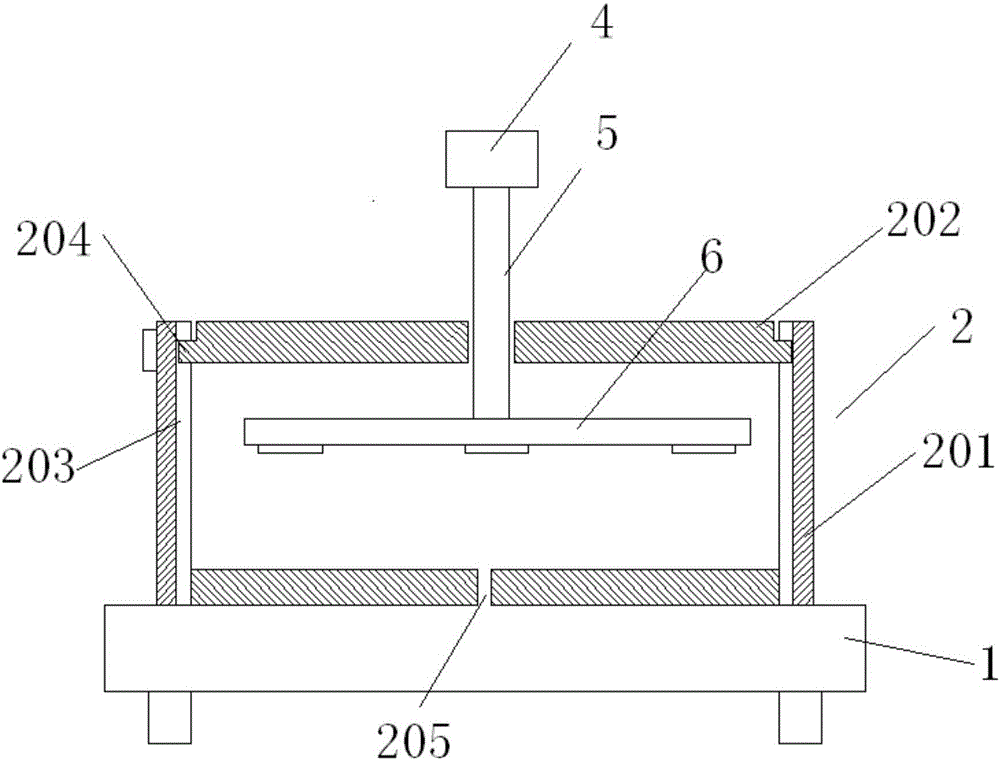

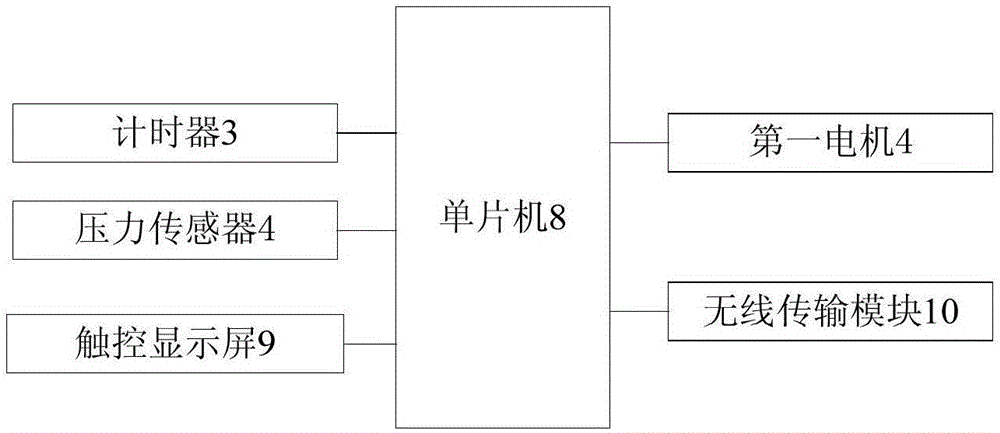

[0016] Such as Figure 1~2 As shown, a kind of equipment that is used for air bag test, comprises base 1, air bag test box body 2, timer 3, the telescopic pressing rod 5 that is driven by the first motor 4 and moves up and down, is arranged at the bottom of telescopic pressing rod The pressing block 6 at the end, a plurality of pressure sensors 7, a single-chip microcomputer 8 and a touch display screen 9; The through hole through which the telescopic push rod 5 passes, the left and right sides of the box body 201 are respectively provided with chute 203, and the box cover 202 is provided with a protrusion 204, and the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com