A lifting simulation system and simulation method guided by a flexible guide rail

A technology of flexible guide rail and simulation system, which is applied in the testing of machine/structural components, instruments, measuring devices, etc., can solve the problems of the working condition that cannot simulate the change of the distance between the two ends of the flexible guide rail, and the stability is not ideal, and achieve high precision Speed control, realize the effect of speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, one embodiment of the present invention is further described:

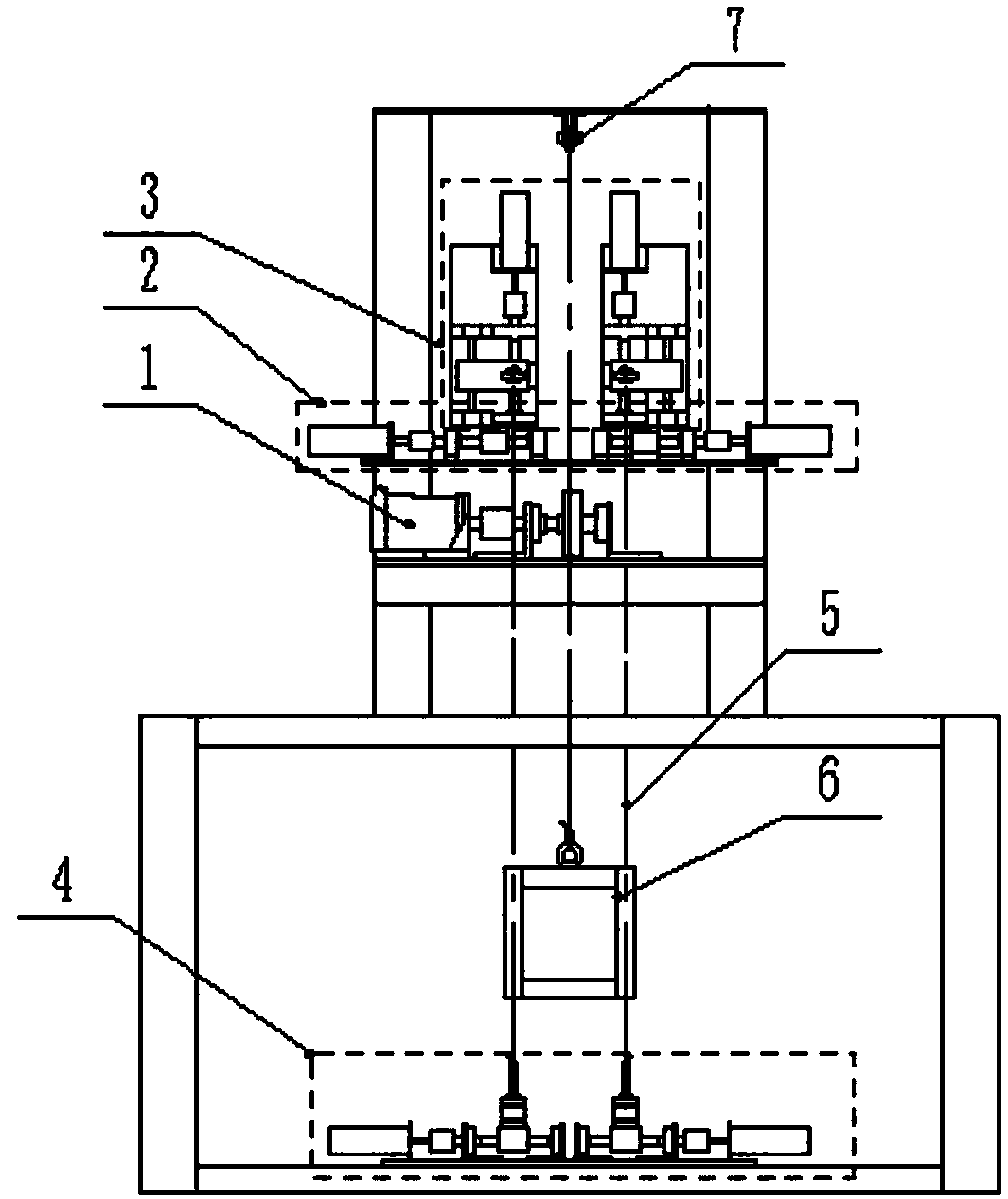

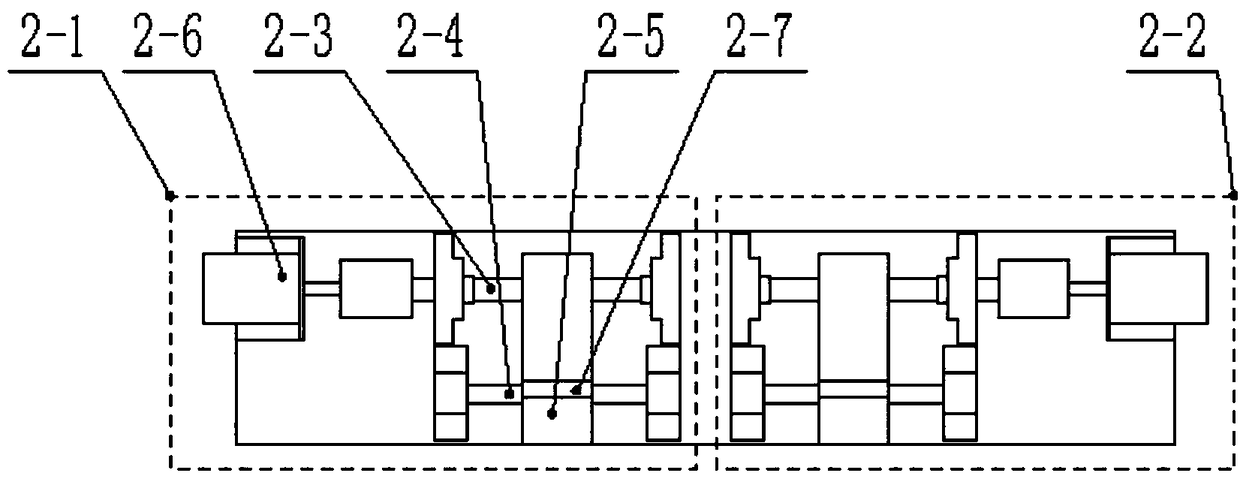

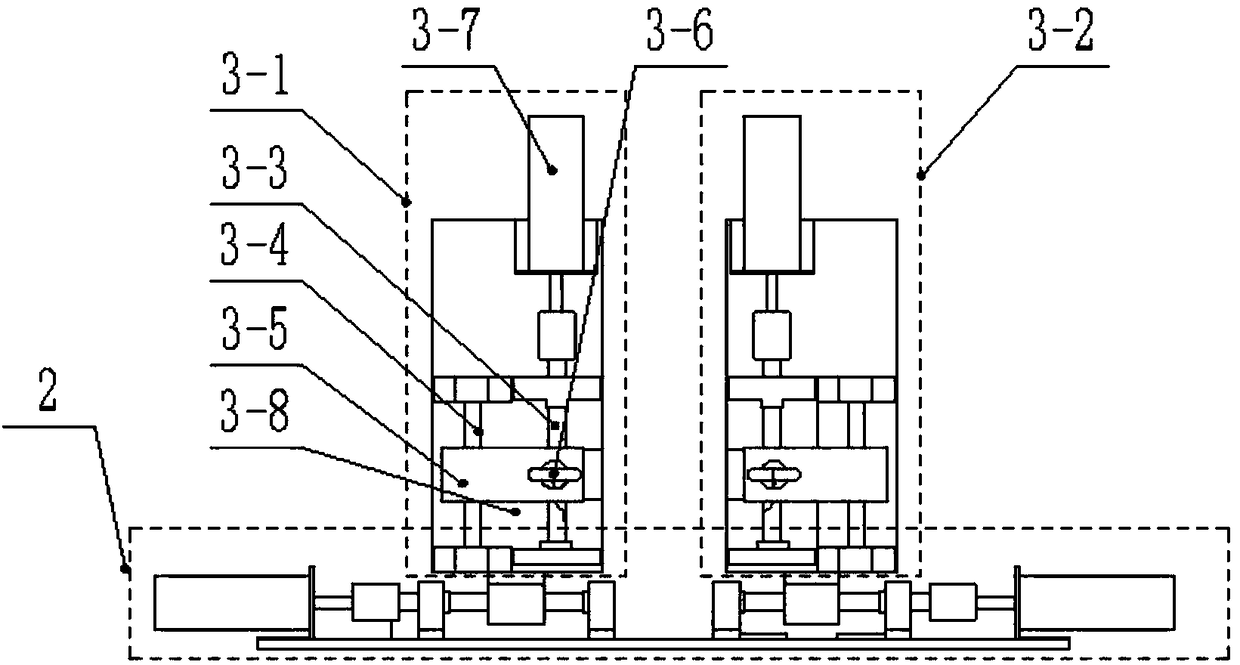

[0026] The flexible guide rail-guided lifting simulation system of the present invention is mainly composed of a drive assembly 1 , an upper spacing adjustment assembly 2 , a tension adjustment assembly 3 , a flexible guide rail 5 , a lower spacing adjustment assembly 4 , a lifting container 6 , and a guide wheel 7 . The tension adjustment assembly 3 is fixed on the tension adjustment assembly connecting plate 2-7 of the upper spacing adjustment assembly 2, the upper spacing adjustment assembly 2 is located on the upper part of the frame, the lower spacing adjustment assembly is located at the bottom, and both flexible guide rails 5 are fixed at one end On the hook one 3-6 of the tension adjustment assembly 3, the other end is fixed on the hook two 4-7 of the lower spacing adjustment assembly 4; the driving assembly 1 lifts the lifting container 6 through a fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com