A three-phase switched reluctance motor sensorless control method and device based on line inductance characteristic point extraction

A feature point extraction, three-phase switching technology, applied in electronic commutation motor control, motor control, AC motor control and other directions, can solve problems such as affecting motor control accuracy, low real-time performance, and deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

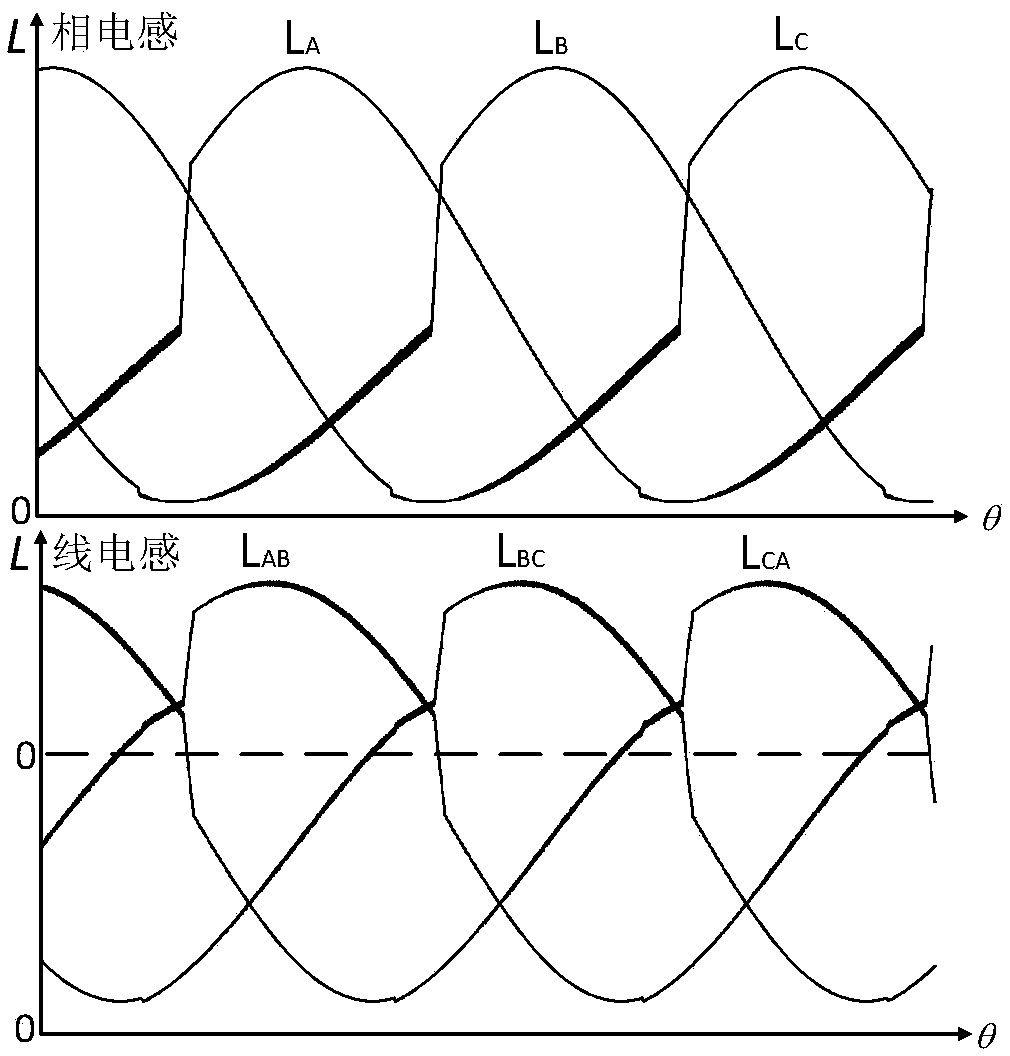

[0057] figure 1 It is a graph of the phase inductance and line inductance of the three-phase switched reluctance motor of the present invention. figure 1 The upper middle is the phase inductance curve, and the lower one is the line inductance curve. In the phase inductance curve, the first conduction phase of the motor in the rotor cycle is the A phase, the subsequent conduction phase is the B phase, and the last conduction phase is the C phase. According to the real-time detection of the current peak value and the bus voltage value of each phase winding, the inductance value of each phase winding is calculated from the formula (1), and the function relationship is obtained from a series of inductance values of each phase winding using the numerical fitting method, as follows: Formula (2) ~ formula (4) shown.

[0058]

[0059] L A (θ)=K 1 sin(θ)-K 2 sin(2θ)+K 3 (2)

[0060] L B (θ)=K 1 sin(θ-2π / 3)-K 2 sin(2θ+2π / 3)+K 3 (3)

[0061] L C (θ)=K 1 sin(θ+2π / 3)-K...

Embodiment 2

[0079] Figure 4 It is a structural block diagram of a three-phase switched reluctance motor position sensorless control device based on line inductance feature point extraction in the present invention. The control device includes a microcontroller, a power conversion circuit drive module, a power conversion circuit, a current detection module, and a voltage detection module. modules, input and output modules, and DC stabilized power supplies. The microcontroller is respectively connected to the power conversion circuit drive module, the current detection module, the voltage detection module and the input and output module; the power conversion circuit is respectively connected to the power conversion circuit drive module, the current detection module and the voltage detection module; wherein:

[0080] The microcontroller is used to send a control signal to the power conversion circuit through the power conversion circuit drive module, and output the chopping control current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com