Multi-target flow shop inverse scheduling method based on uncertain environment

A scheduling method and multi-objective technology, applied in the field of multi-objective flow shop inverse scheduling, can solve problems such as difficulty in effectively dealing with interference conditions, and achieve the effects of improving initial population diversity, local search performance, and individual quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

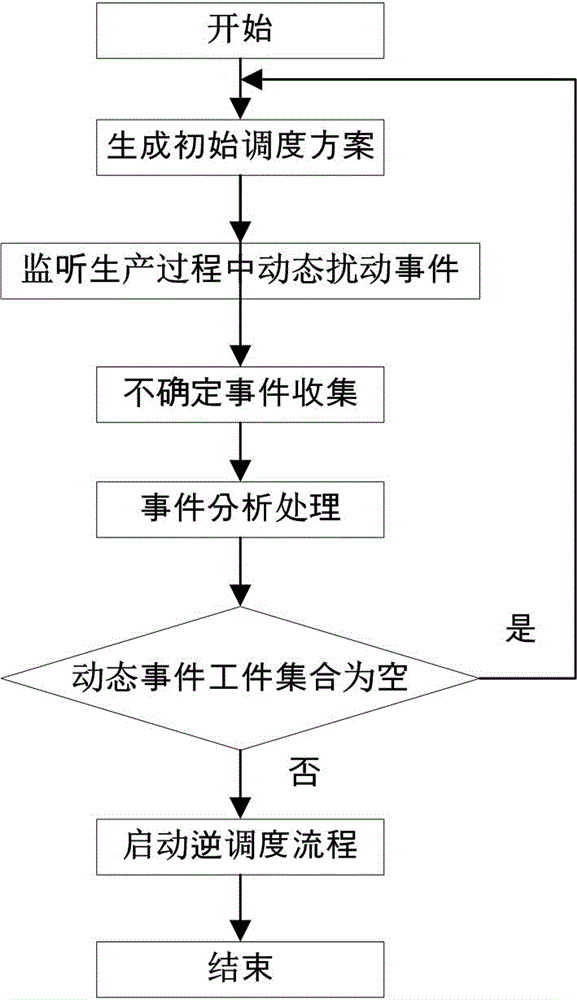

[0050] refer to figure 1 , a multi-objective flow shop inverse scheduling method based on uncertain environment, including the following steps:

[0051] 1. Establish a multi-objective flow shop inverse scheduling problem model based on uncertain environment

[0052] This problem mainly considers workshop efficiency and workshop system fluctuations, including three objectives:

[0053] (1) Adjust the processing parameters as little as possible, namely:

[0054] (1)

[0055] in,

[0056] (2) Completion time and as close as possible to the original target, namely:

[0057] (2)

[0058] in,

[0059] (3) Minimize the adjustment amount of the scheduling system, namely:

[0060] (3)

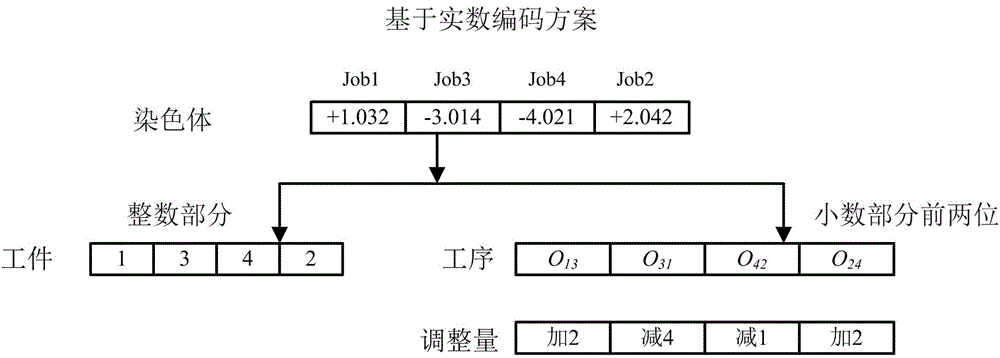

[0061] Among them, H represents the Hamming distance, that is, the direct individual difference between two chromosomes

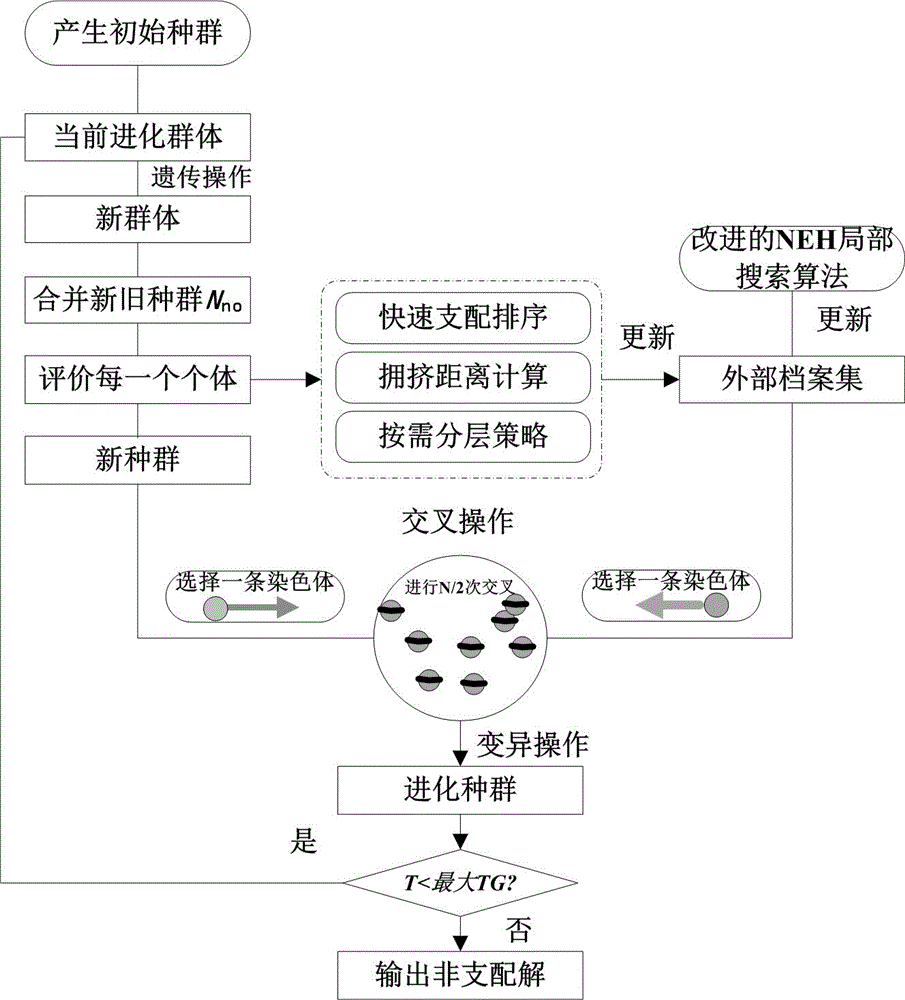

[0062] The improved hyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com