A torque-increasing permanent magnet retarder

A retarder, permanent magnet technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electromechanical device, etc., can solve the problems of power consumption of automobile, difficult grading control, magnetic field cannot be completely shielded, etc. The effect of braking torque, reasonable structure design and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

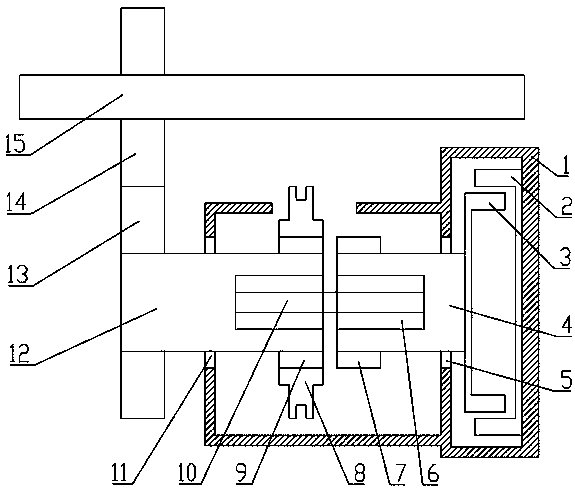

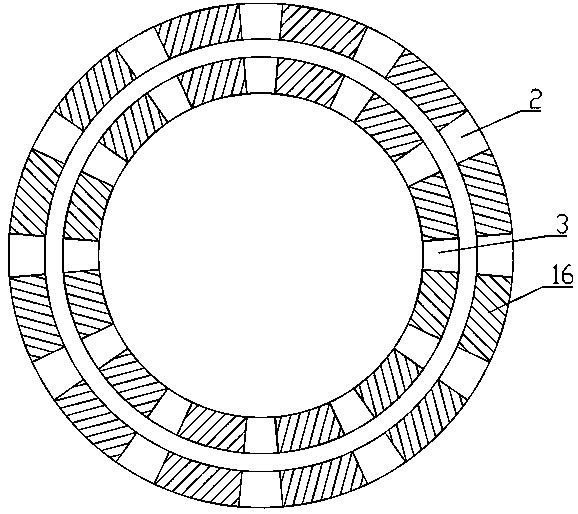

[0022] Attached below figure 1 , 2 A torque-increasing permanent magnet retarder of the present invention is described in detail below.

[0023] as attached figure 1 , 2 As shown, a torque-increasing permanent magnet retarder of the present invention has a structure comprising a housing 1, a stator 2, a rotor 3, a rotor shaft 4 and a combination assembly;

[0024] The stator 2 is circular, the first end of which is fixedly installed in the housing 1, and the second end extends to the outer ring of the rotor 3, and is in clearance fit with the rotor 3;

[0025] The rotor shaft 4 is rotatably mounted on the housing 1 through the second bearing 5, one end of which extends into the interior of the stator 2, and the rotor shaft 4 is coaxial with the stator 2;

[0026] The rotor 3 is circular, fixedly mounted on the end of the rotor shaft 4 close to the stator 2, and coaxial with the rotor shaft 4;

[0027] The combined assembly includes a driven shaft 12, a first combined gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com