Mounting locating tool based on double-layer manipulator and use method thereof

An installation and positioning, manipulator technology, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of complicated leveling process, increased equipment maintenance time, time-consuming installation, leveling and film transfer testing, etc., to achieve reasonable structure, The effect of shortening the leveling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

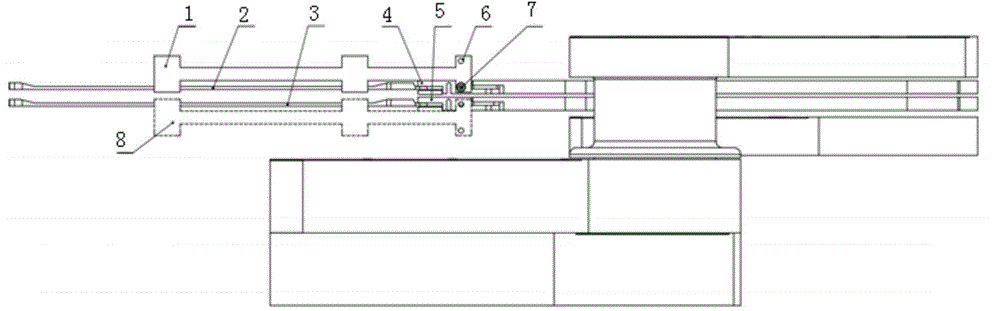

[0011] Refer to attached figure 1 , based on the installation and positioning tooling of the double-layer manipulator, including the installation and positioning substrate 1, the positioning hole 6 for the front finger of the lower layer of the manipulator, and the positioning hole 7 for the front finger of the upper layer of the manipulator, wherein the installation and positioning base plate 1 is a symmetrical structure for positioning the front end of the upper and lower layers of the manipulator Finger, and the accuracy of the positioning hole 6 of the front end finger of the lower floor of the manipulator and the positioning hole 7 of the upper front end finger of the manipulator depend entirely on the guarantee of machining accuracy.

[0012] The specific installation method: first align and fix the positioning hole 7 of the upper front finger of the manipulator on which the positioning substrate 1 is installed and the mounting screw hole on the upper arm 4 of the manipul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com