Adjustable damping rail guide vehicle

A shuttle car, adjustable technology, applied in the direction of conveyors, packaging, storage devices, etc., can solve the problems of warehouse production operations and personnel safety damage, affect the service life of the shuttle car, and cannot realize modular production, etc., to achieve ease of use and Maintenance and adjustment, wide range of use, stable walking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

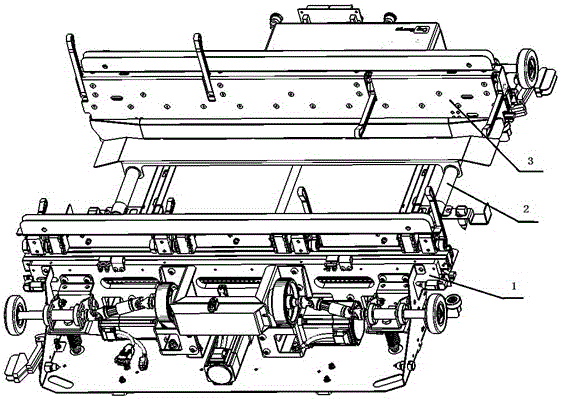

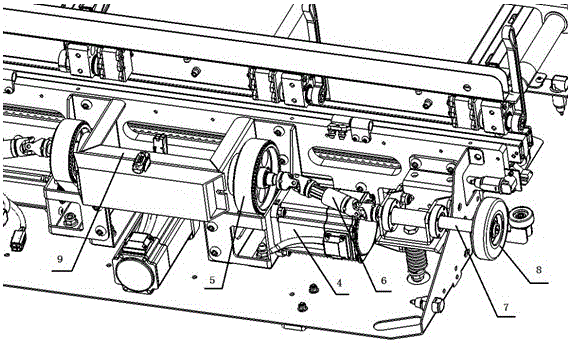

[0018] Embodiment one, such as figure 1 , 2 , 3, an adjustable shock-absorbing shuttle vehicle of the present invention includes a frame body, and the frame body includes a symmetrical front frame 1 and a rear frame 3, the left and right ends of the front frame 1 and the rear frame 3 Adjustment seats 10 are fixed at the left and right ends, the adjustment between the adjustment seat 10 at the left end of the front frame 1 and the adjustment seat 10 at the left end of the rear frame 3 and the adjustment between the adjustment seat 10 at the right end of the front frame 1 and the right end of the rear frame 3 Adjustment shafts 2 that can move back and forth are movably connected between the seats 10 , and a locking mechanism is provided at the connection between the adjustment shafts 2 and the adjustment seats 10 . After the locking mechanism is released, the length of the two ends of the adjustment shaft 2 penetrating into the adjustment seat 10 can be increased or shortened, ...

Embodiment 2

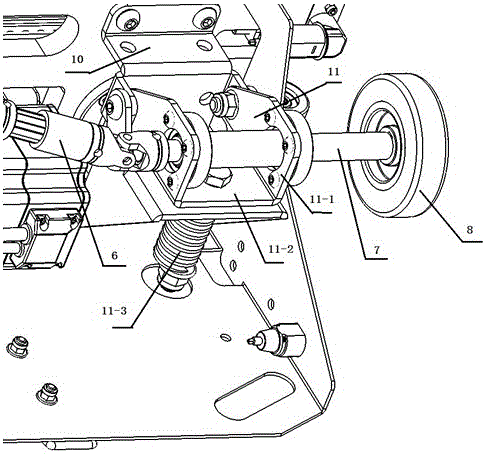

[0021] Embodiment two, such as Figure 4 As shown, the swing seat 11 adopts a rectangular structure, the axle 7 runs through the swing seat 11 left and right, and the front and rear sides of the swing seat 11 are rotationally connected with the connecting seat 12 located above the swing seat 11, the connecting seat 12 is connected with the adjustment seat 10, and connected The seat 12 is provided with a vertical damping spring 11-3, and a connecting rod is worn in the damping spring 11-3, and the upper end of the connecting rod extends out of the damping spring 11-3 and is provided with a fastening nut 13, and the lower end of the connecting rod Pass through the connecting seat 12 and connect with the swing seat 11. When the wheel 8 vibrated, the swing seat 11 swung left and right, and the connecting rod could be stretched up and down simultaneously, and under the elastic force of the shock-absorbing spring 11-3, the shock-absorbing effect was played. Others are the same as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com