Compaction degree sensor, dynamic compaction machine and compaction degree detection method

A compactness and sensor technology, which is applied in soil material testing, material inspection products, soil protection, etc., can solve the problems of untimely detection, low density of detection points, large human error, etc., to ensure consistency and reduce under-tamping or the effect of overtamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

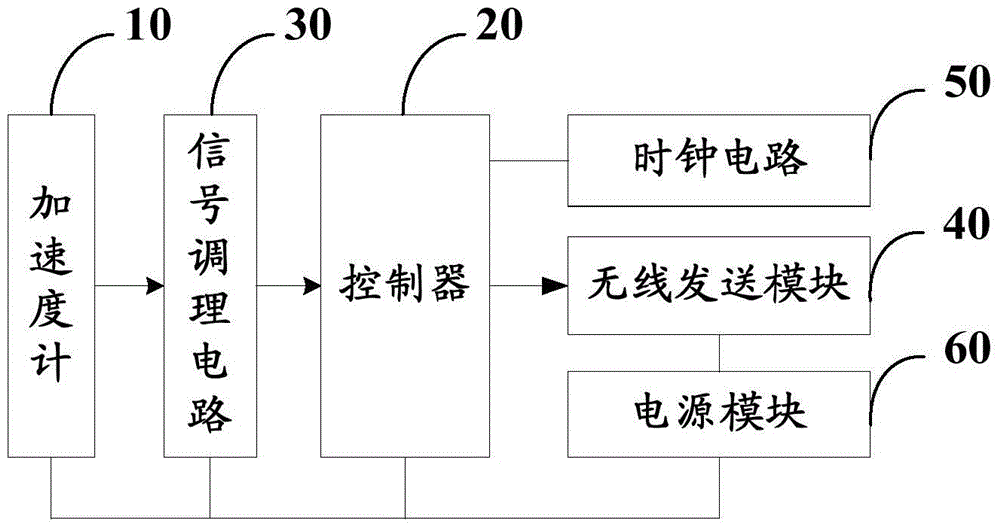

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0033] For ease of understanding, the terms mentioned in the present invention are explained or exemplified below.

[0034] The degree of compaction refers to the compactness of the soil after the ground has been treated by the dynamic compaction method, and is an important measure of the construction quality.

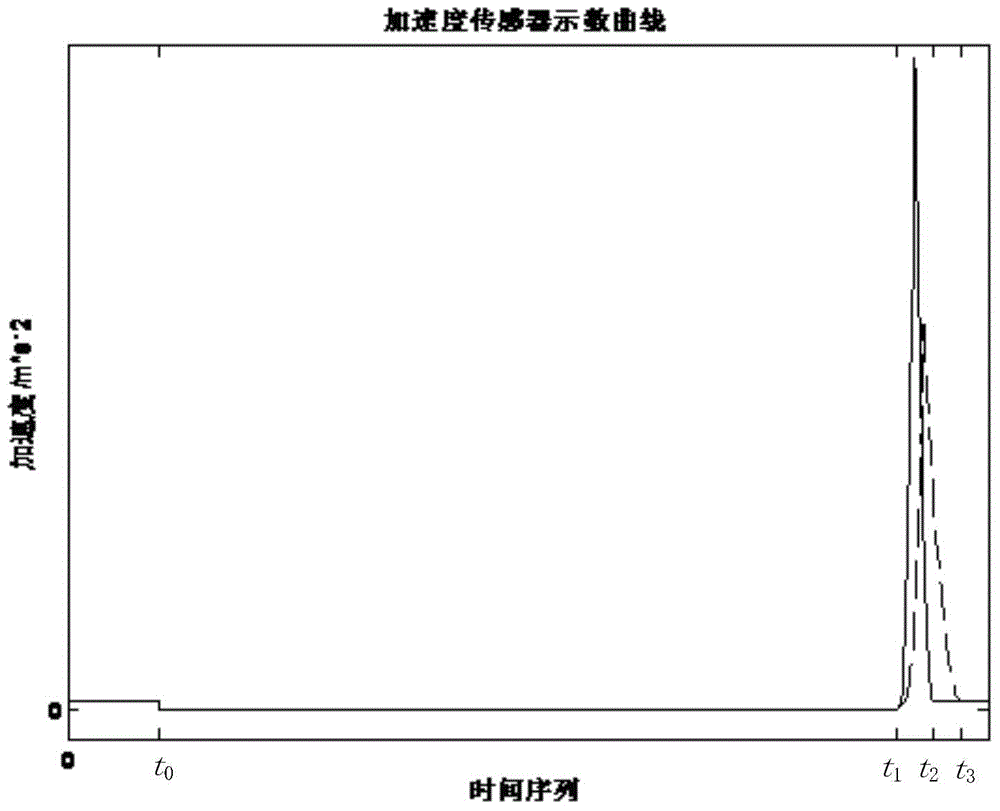

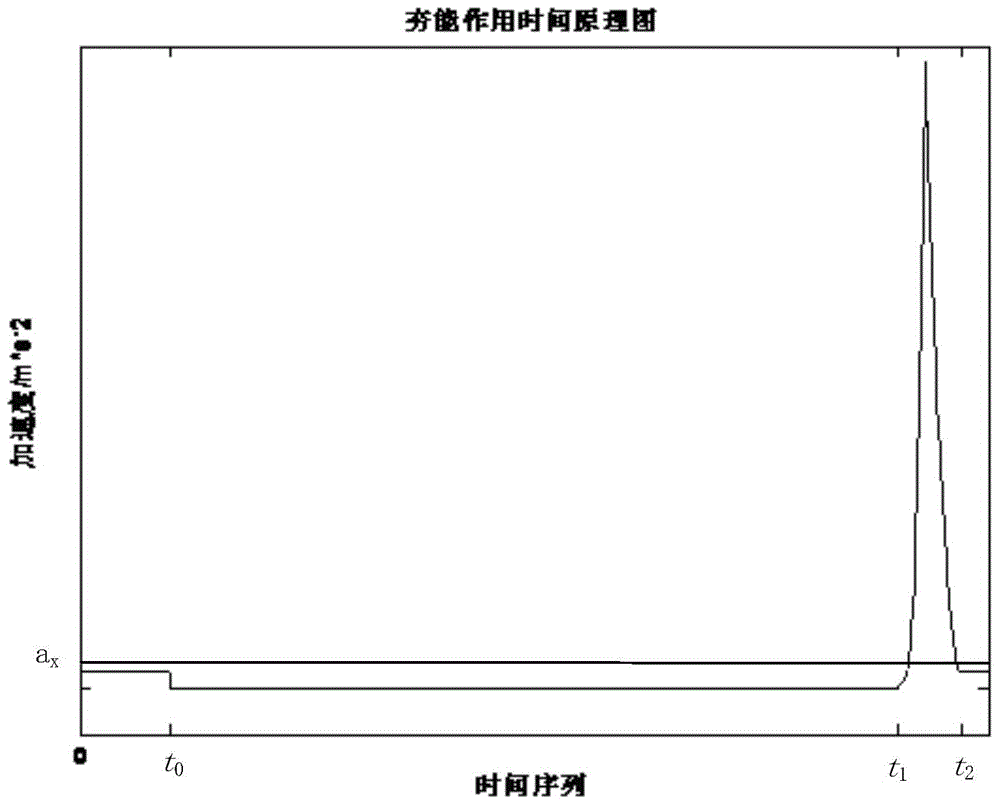

[0035] Tamper energy action time refers to the time interval from when the rammer touches the ground to when its velocity first decreases to zero.

[0036] The dynamic compaction machine is a kind of construction machinery equipment widely used in foundation treatment at present. The dynamic tamping machine uses lifting equipment to raise the rammer to a certain height, then releases the rammer to let it fall freely, and uses the strong impact force generated when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com