Prestress groove plate with horseshoe-shaped web bottom

A horseshoe-shaped, prestressed technology, applied to building materials, building components, buildings, etc., can solve the problem of excessive distribution of web reinforcement, to solve the problem of excessive distribution of web reinforcement, ensure structural bearing capacity, and reduce layer height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand the present invention.

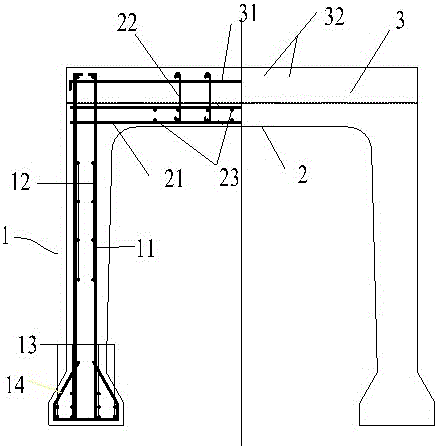

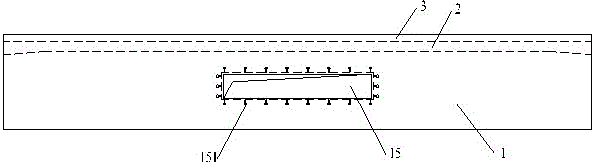

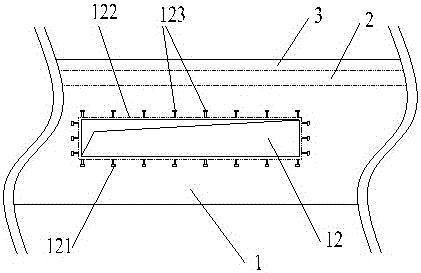

[0019] A prestressed channel plate with a horseshoe-shaped web bottom, including two webs 1, a wing 2, and a concrete pouring layer 3 covering the tops of the web 1 and the wing 2, and the web 1 is located at both ends of the wing 2 bottom. The interior of the web 1 is provided with a plurality of stirrups 11 , a plurality of web non-prestressed longitudinal reinforcements 12 , a plurality of web prestressed longitudinal reinforcements 13 and horseshoe-shaped structural reinforcements 14 . The bottom of the web 1 is horseshoe-shaped. The stirrup 11 is located in the middle of the web 1 . The plane where the steel bars on both sides of the stirrup 11 are located is parallel to the axial cross-section of the web 1 . The non-prestressed longitudinal reinforcement 12 of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com