Automatic lock body with separated upper lock catch and anti-swing bolt

An automatic lock and lock body technology, applied in the field of locks, can solve problems such as unreasonable structural design, hitting the door frame, shaking, etc., and achieve the effect of reducing professional knowledge, easy opening, and fewer mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

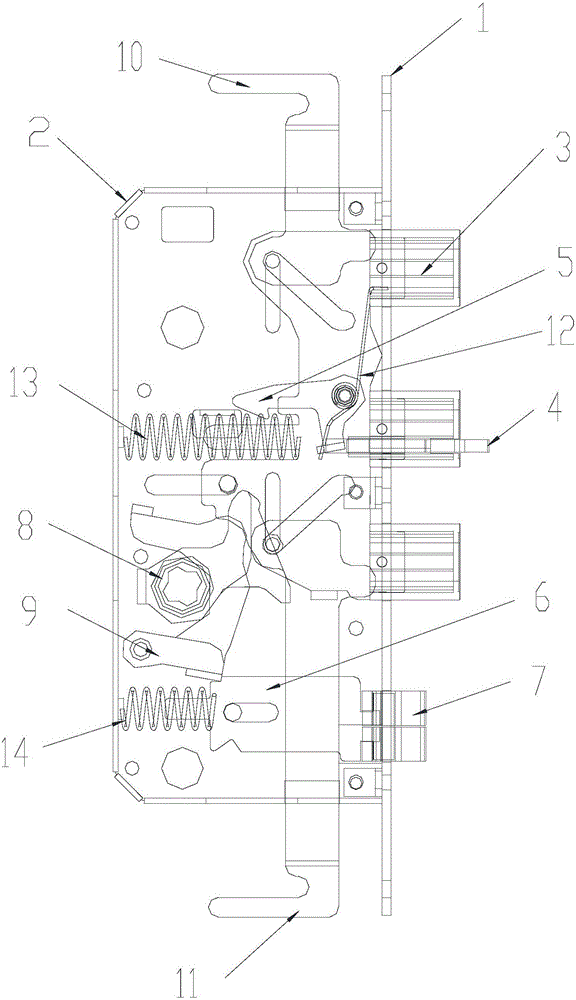

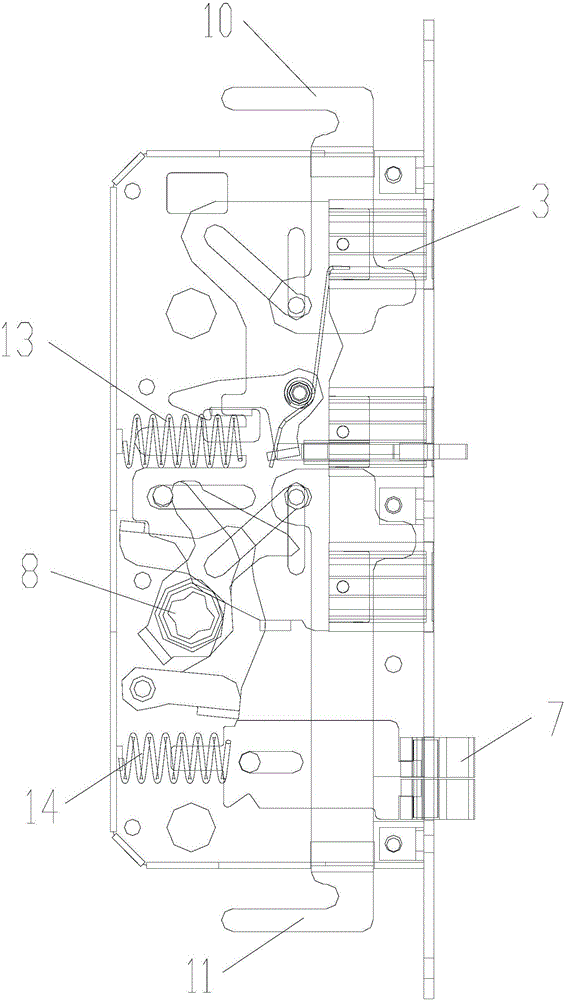

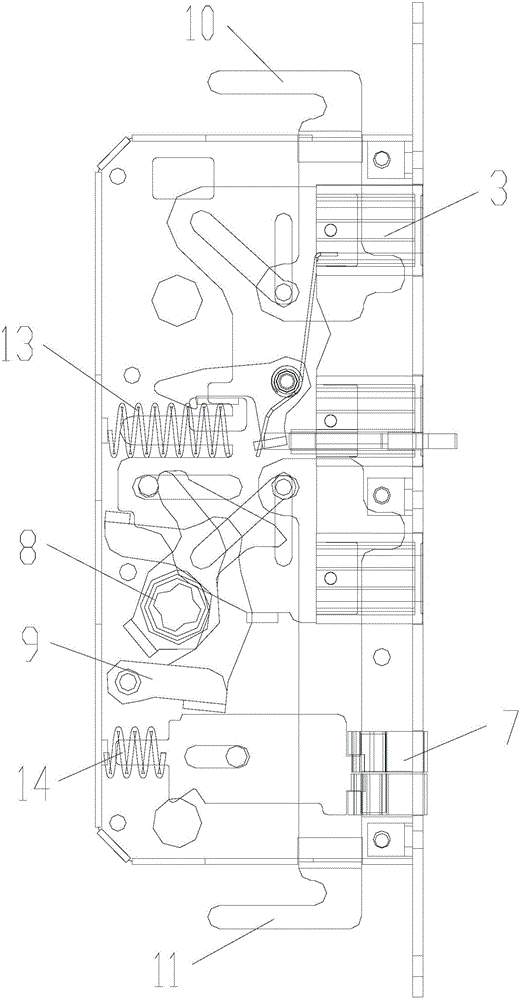

[0022] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 11 As shown, the present invention includes a lock body panel 1, a lock body shell 2, a main tongue plate 3, an auxiliary tongue plate 6, and a shift fork 8. The lock body panel 1 is fixed on one side of the lock body shell 2, and in the lock The main tongue plate 3 and the auxiliary tongue plate 6 are installed in the body shell 2, and the main tongue plate 3 is located above the auxiliary tongue plate 6; a first return spring 13 is installed between one end of the main tongue plate 3 and the lock body shell 2, The other end of the main tongue plate 3 protrudes from the lock body panel 1, and is provided with a top tongue 4, and the main tongue plate 3 is connected with an upper lock key 5 and a reset button 12; the shift fork 8 is located in the lock body shell 2 , and is in contact with the main tongue plate 3; a second return spring 14 is installed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com