Blow-by Gas Passage Structure

一种窜气、通路的技术,应用在曲轴箱通风、发动机元件、机器/发动机等方向,能够解决油成分分离效率下降、阻挡效果下降等问题,达到防止窜气通过间隙、提高阻挡效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

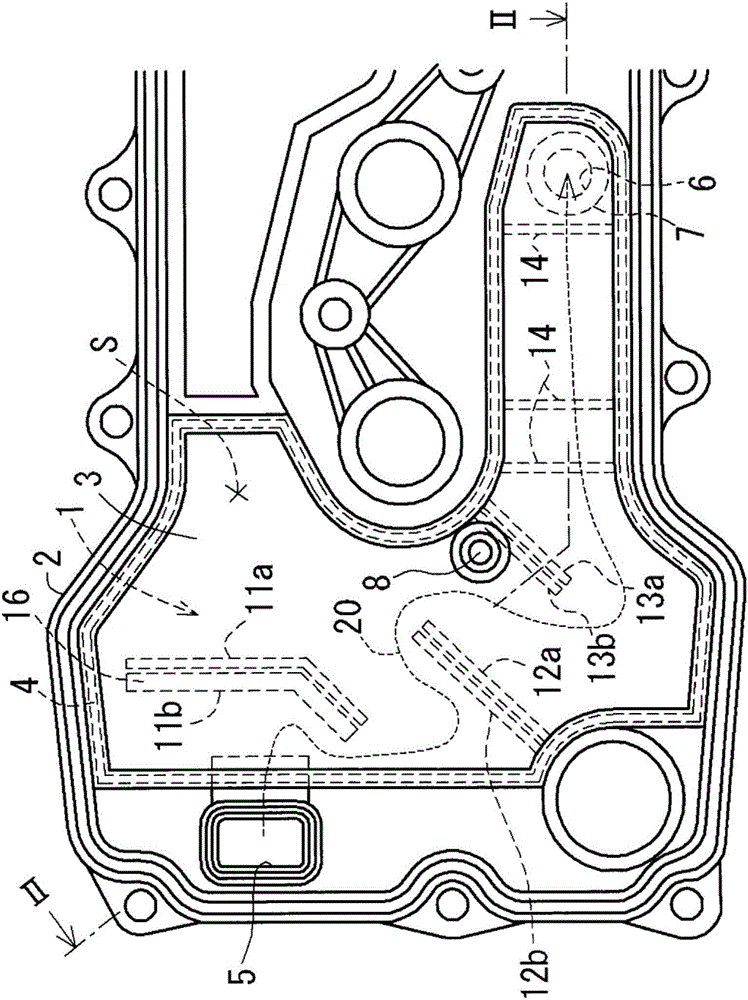

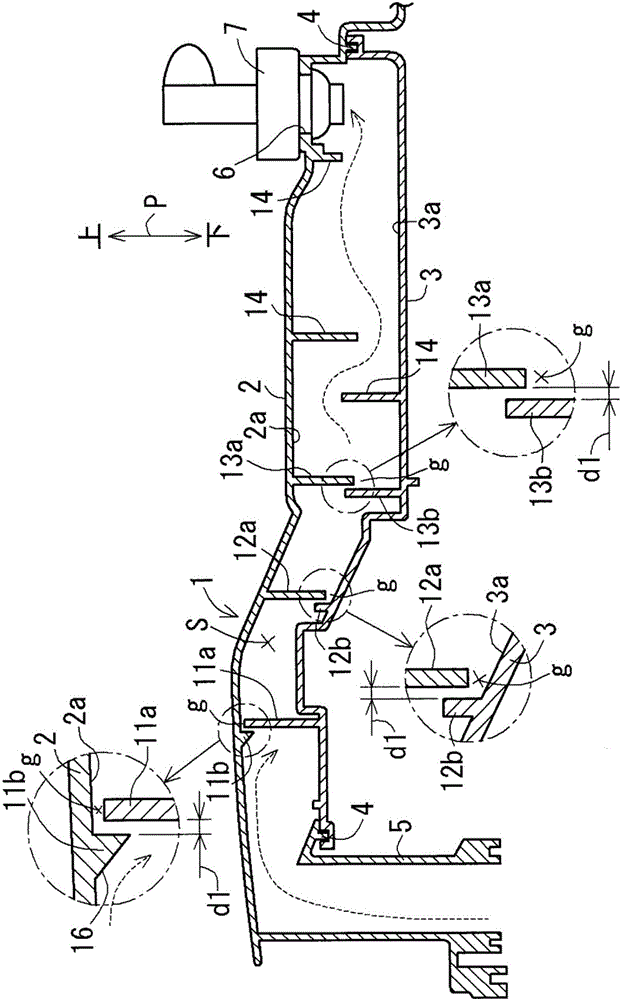

[0042] (1) The structure of the channel structure of the blow-by gas

[0043] Such as figure 1 and figure 2 As shown, the blow-by gas passage structure 1 of this embodiment is provided in the separation chamber S formed between the cylinder head cover 2 and the baffle plate 3 . The passage structure 1 for blow-by gas constitutes a passage for the blow-by gas introduced into the separation chamber S. As shown in FIG.

[0044] The cylinder head cover 2 is formed of a resin material, and is formed in a box shape with an open bottom. In addition, the baffle plate 3 is formed of a resin material, and is joined to the head cover 2 at a welded portion 4 so as to close the bottom side of the head cover 2 by vibration welding. In addition, the head cover 2 and the baffle plate 3 respectively include facing surfaces 2 a , 3 a that face each other in the vertical direction P of the head cover 2 . In addition, a planar direction substantially perpendicular to the vertical direction ...

Embodiment 2

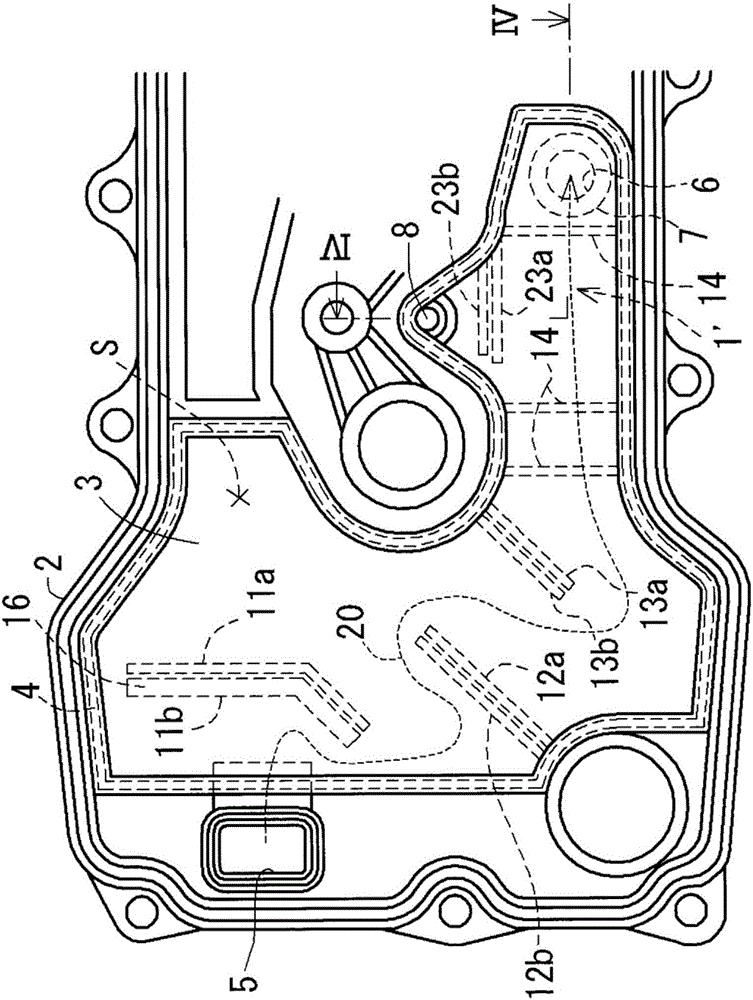

[0062] Next, the channel structure of the blow-by gas in the second embodiment will be described. In addition, in the blow-by gas passage structure of the present embodiment 2, structural parts substantially the same as those of the blow-by gas passage structure 1 of the above-mentioned embodiment 1 are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0063] (1) The structure of the channel structure of the blow-by gas

[0064] Such as image 3 and Figure 4 As shown, the blow-by gas passage structure 1' of this embodiment is provided in the separation chamber S formed between the cylinder head cover 2 and the baffle plate 3. An oil leak hole 8 is formed in the baffle plate 3 in the vicinity of the discharge port 6 (that is, the PCV valve 7 ) of the head cover 2 .

[0065] The blow-by gas passage structure 1' includes first ribs 11a, 12a, 13a and second ribs 11b, 12b, 13b for detour, rib 14 for detour, and first rib 23a and second ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com