Wind turbine generator system yaw system control performance optimization method and system

A technology of wind turbines and yaw systems, applied in the control of wind turbines, wind turbines, engine control, etc., can solve the problems of low power generation, lack of pertinence, and low service life of related equipment, so as to increase power generation , Improve the optimization accuracy and optimize the effect of yaw error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical features and effects of the present invention more obvious, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings. The present invention can also be described or implemented in other different specific examples. The equivalent transformations done within all belong to the protection category of the present invention.

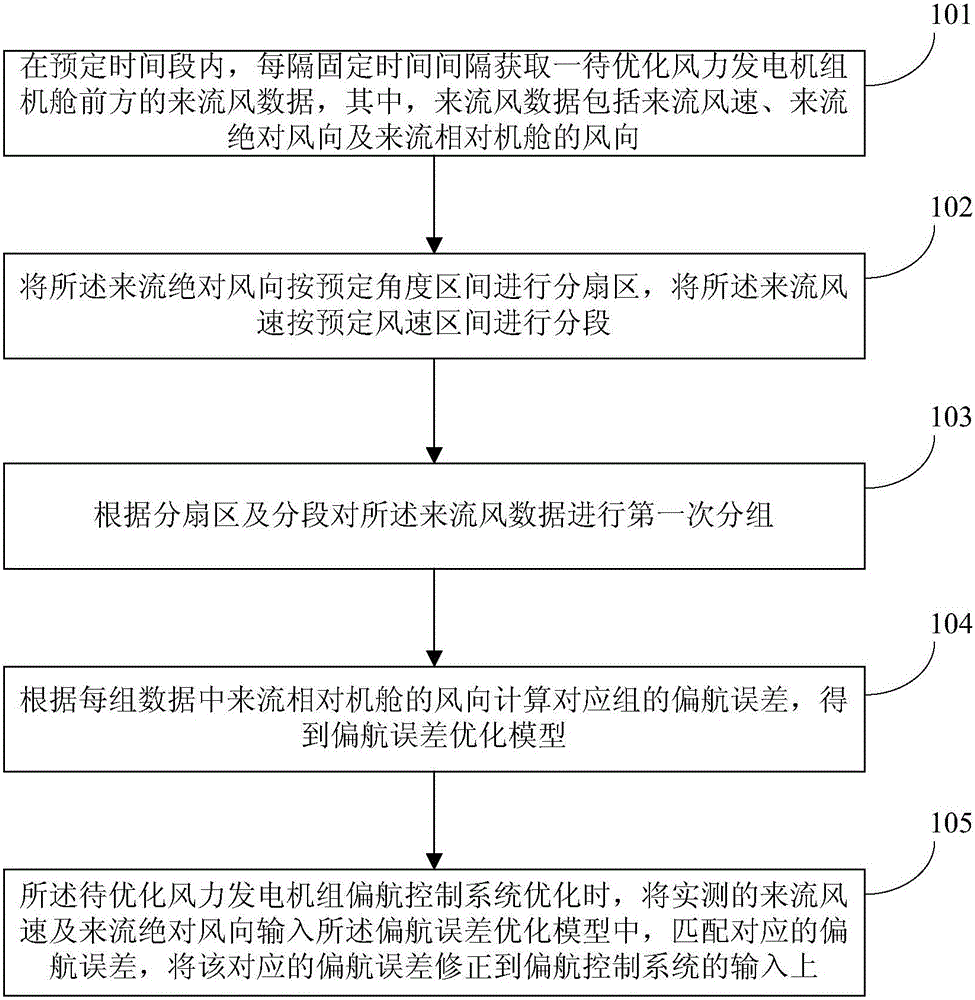

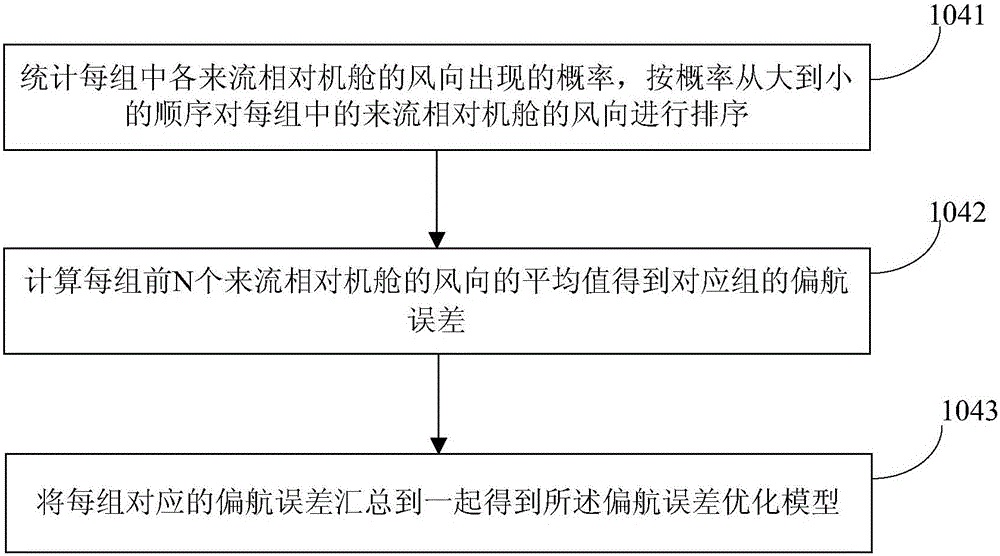

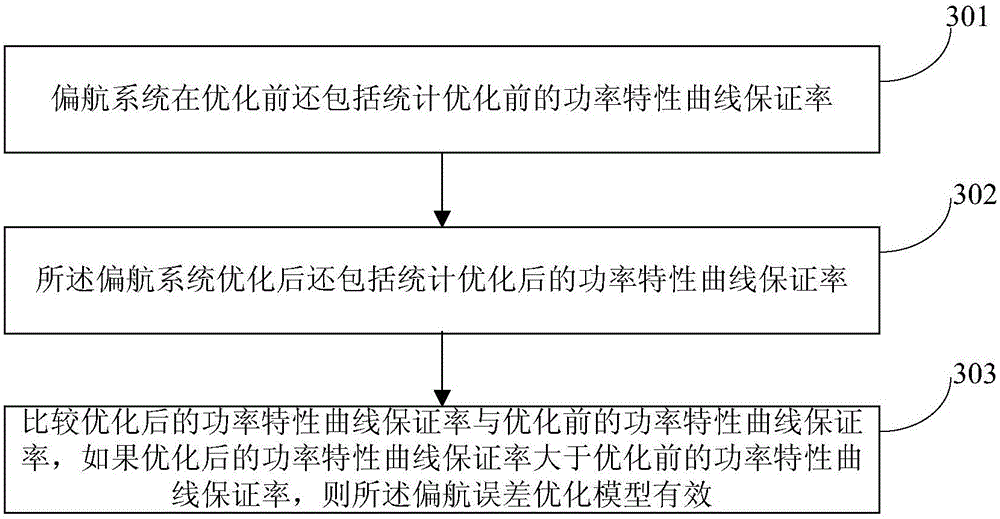

[0028] like figure 1 as shown, figure 1 It is a flow chart of a method for optimizing the control performance of a yaw system of a wind power generating set according to an embodiment of the present invention. In this embodiment, different optimization strategies can be adopted for different types of wind turbines at different incoming wind speeds, and the yaw error of the yaw system can be optimized in a targeted manner, improving the optimization accuracy of the yaw error.

[0029] Specifically, the method for optimizing the control performance of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com