A self-circulating multi-stage axial flow compressor

A technology for axial flow compressors and gas pipelines, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems that noise cannot be considered, and the difficulty of pipeline design and layout can be solved, so as to reduce unsteady loads and expand Effect of stability margin and reduction of static/rotational interference noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

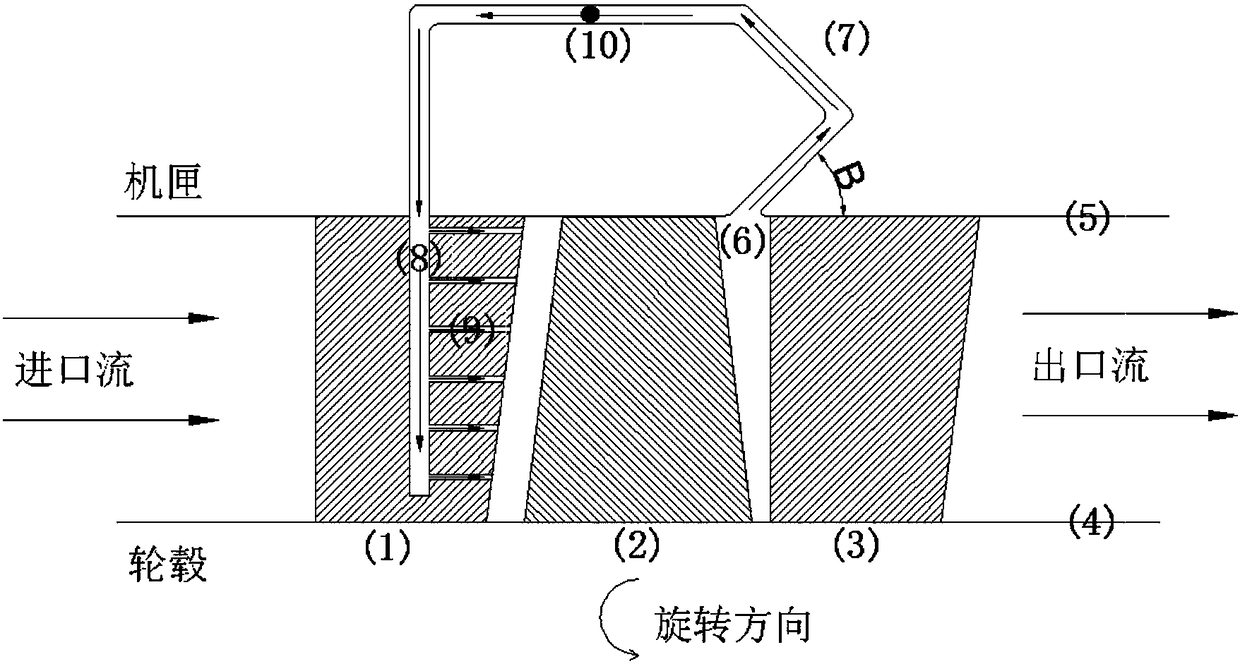

[0026] Such as figure 1 As shown, a self-circulating multi-stage axial flow compressor includes: a casing 5, a stator 1, a rotor 2, and an air-introduction pipe 7 for air-induction, and the air-induction hole 6 at one end of the air-induction pipe is located at the rotor blade Inside the casing wall at the sharp trailing edge, it is used to lead out the tip leakage vortex of the rotor 2, and improve the flow field of the main flow path, especially at the surge working point, so as to achieve the purpose of expanding and stabilizing the compressor. The air outlet at the other end of the bleed air pipe communicates with the main air blow pipe 8 on the stator 1, so that the gas in the air bleed pipe 7 is blown out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com