Low-power-consumption maintaining and failure safety turnoff mechanism of underwater gate valve executor

A technology for underwater gate valves and holding mechanisms, applied to valve details, valve devices, mechanical equipment, etc., can solve the problems of large energy consumption, inability to realize the safe automatic shutdown function of underwater gate valves, energy waste, etc., and achieve the goal of reducing energy The effect of low consumption, short reaction time to failure and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

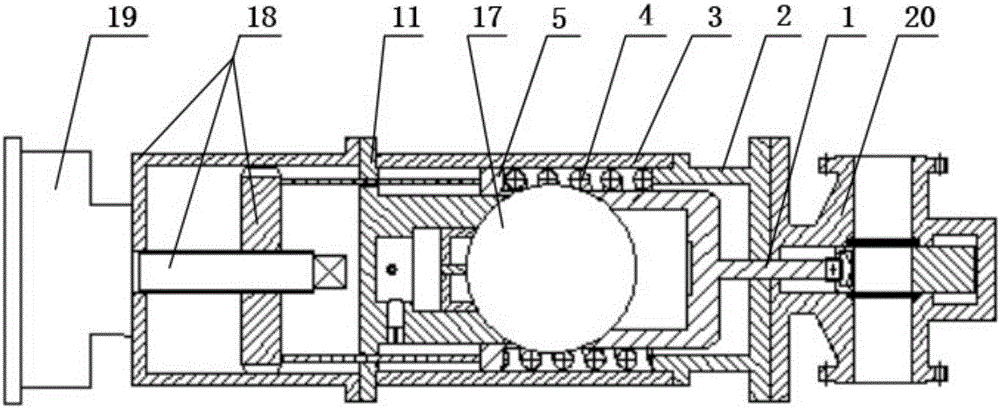

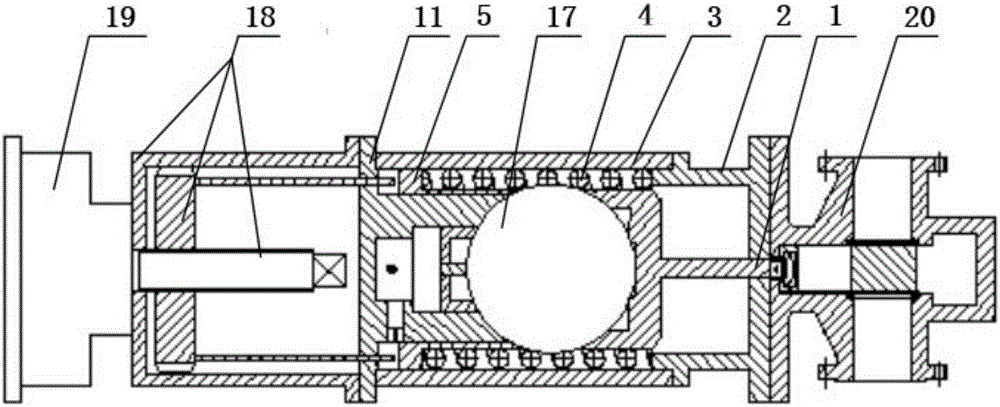

[0021] figure 1 and figure 2 They are schematic diagrams of the structural layout of the underwater gate valve actuator in the low power consumption maintenance and fail-safe shutdown states, the valve stem 1 is connected to the underwater gate valve 20, and the transmission device (screw) 18 and motor 19 are very common. , so it does not belong to the scope of the present invention, the part between the transmission device (leading screw) 18 and the gate valve 20 is the core part of the main body of the present invention, mainly composed of valve stem 1, front cover 2, housing 3, rear cover 11, return spring 4. It is composed of spring bracket 5, mechanical locking mechanism 17 and other parts.

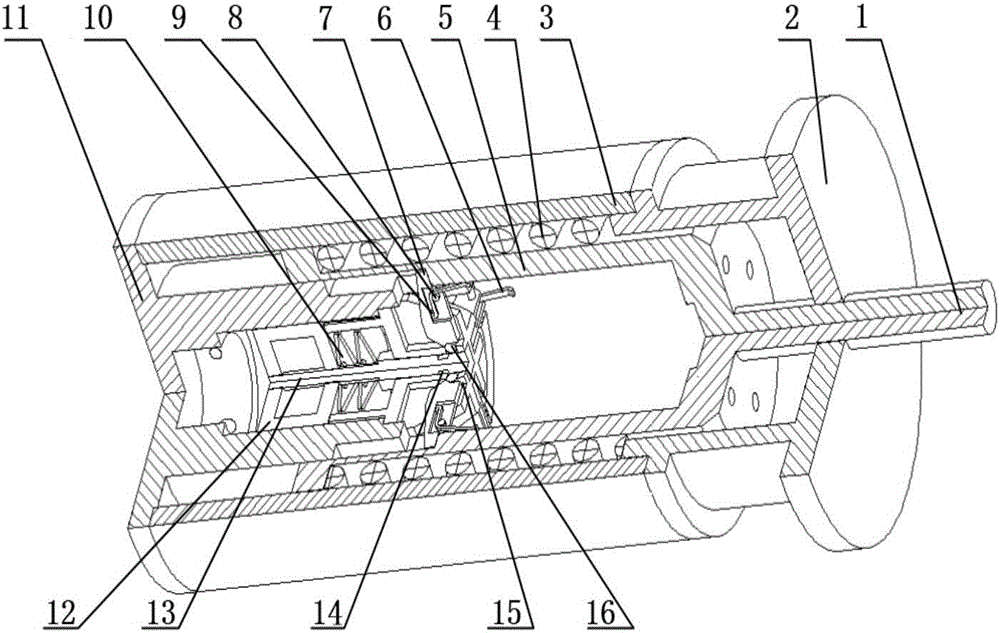

[0022] combine Figure 2-7 , the front cover 2, the housing 3, and the rear cover 11 in the present invention are formed as a whole by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com