A sheet supply device and an image forming device

A technology of a supply device and a feeding device, which is applied in the direction of electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, and electrography, and can solve problems such as inability to supply sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0049] 1. Overview of image forming apparatus

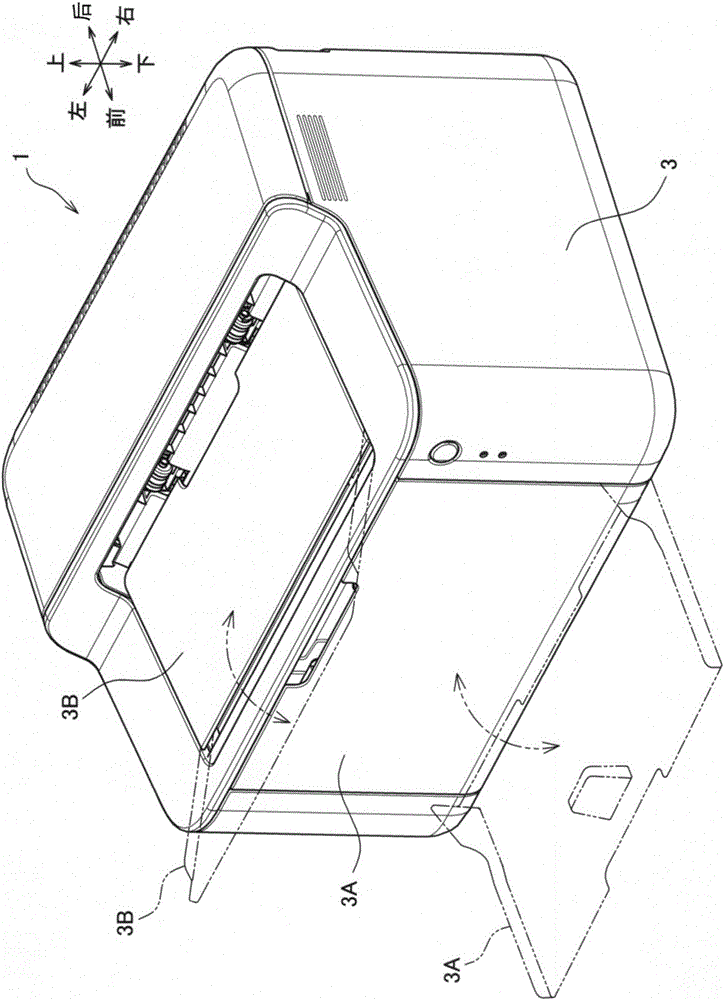

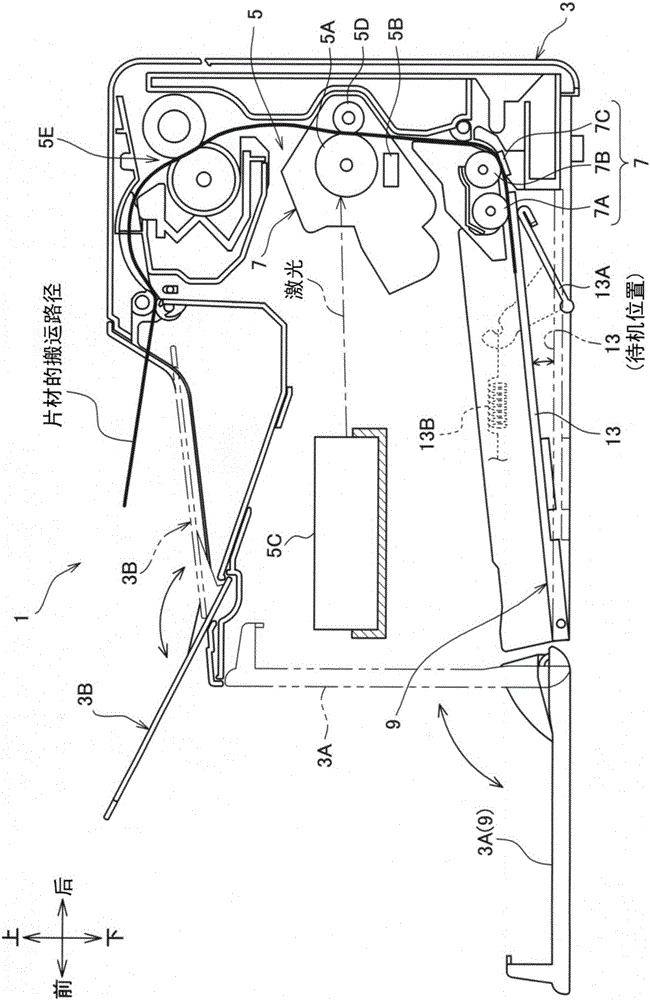

[0050] exist figure 1 An image forming mechanism 5 is accommodated in a housing 3 of the illustrated image forming apparatus 1 (see figure 2 ). A paper feed cover 3A is swingably assembled on the front side of the housing 3 . A discharge cover 3B is assembled to the upper surface of the housing 3 so as to be able to swing.

[0051] Such as figure 1 As shown, when the image forming operation is not performed, the user rotates the paper feed cover 3A and the paper discharge cover 3B forward as indicated by the two-dot chain line to open the paper feed cover 3A and the paper discharge cover 3B.

[0052] and, if figure 2 As shown by the solid line in , in the image forming apparatus 1 with the sheet feeding cover 3A and the sheet output cover 3B opened, the user inserts a sheet from the opening opened by opening the sheet feeding cover 3A, and places the sheet on the press. plate 13.

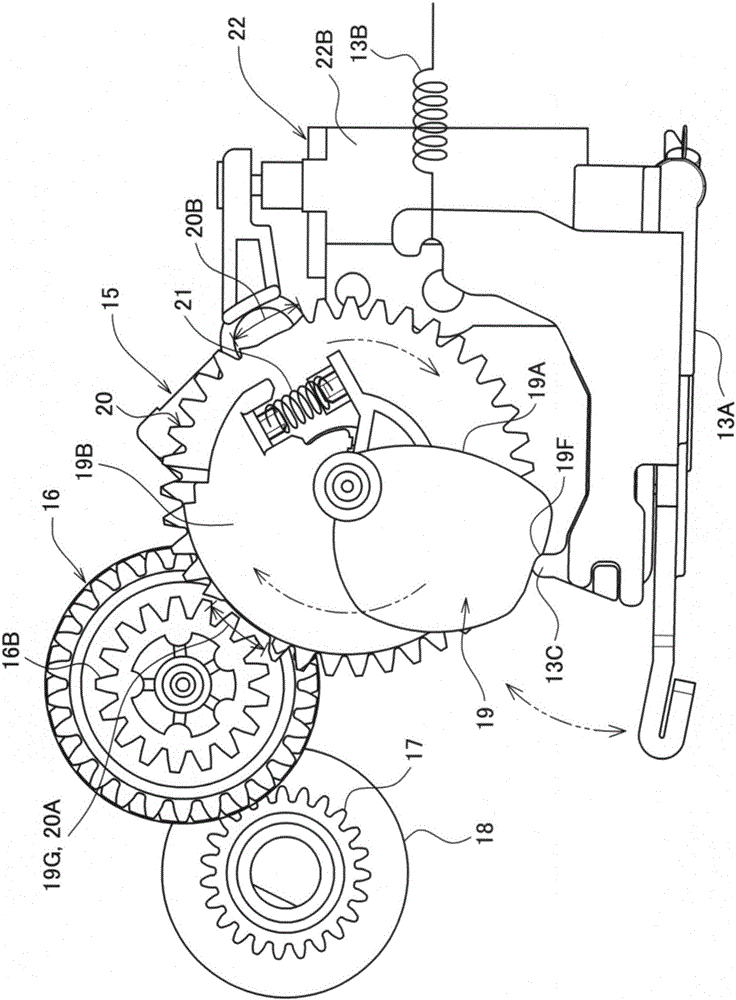

[0053] In addition, when the user place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com