Rotating joint

A technology of rotating joints and spindles, which is applied to rotating joints. field, it can solve problems such as institutional swelling, complexity, and lack of data links, and achieve the effect of high safety performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained in conjunction with the accompanying drawings as follows.

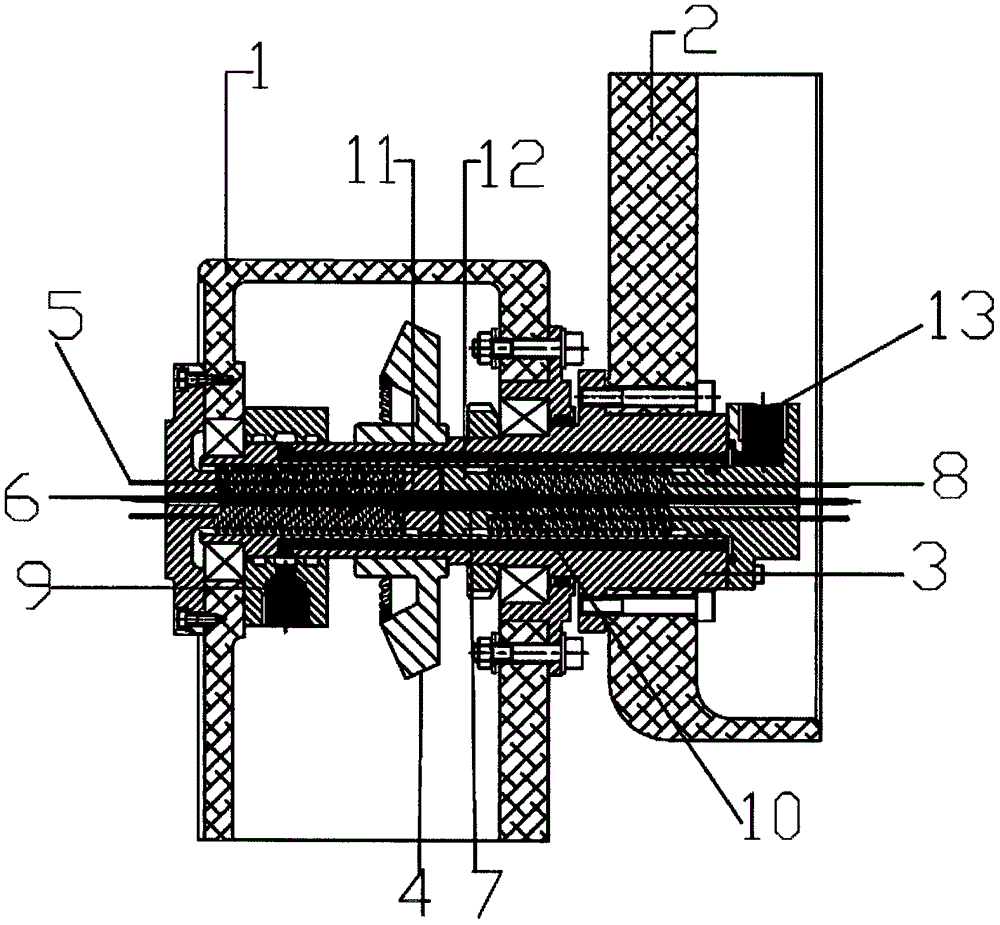

[0024] see figure 1 , the present invention discloses a rotary joint, comprising a relatively stationary first mechanical arm 1 and a circularly moving mechanical arm 2 relative to the first mechanical arm 1, a main shaft 3 with a hollow structure and a power input device 4, the main shaft 3 contains a first conductor 11 and a second conductor 12 wound with a coil, and the first conductor 11 and the second conductor 12 are separated from each other, the first conductor 11 rotates concentrically with respect to the main shaft 3, the second The two conductors 12 are stationary relative to the main shaft 3, the first conductor 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com