Method for digitally simulating pre-bending of fracture steel plate

A pre-bending, steel plate technology, applied in the medical field, can solve the problems of prolonging operation time, injury, blood loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

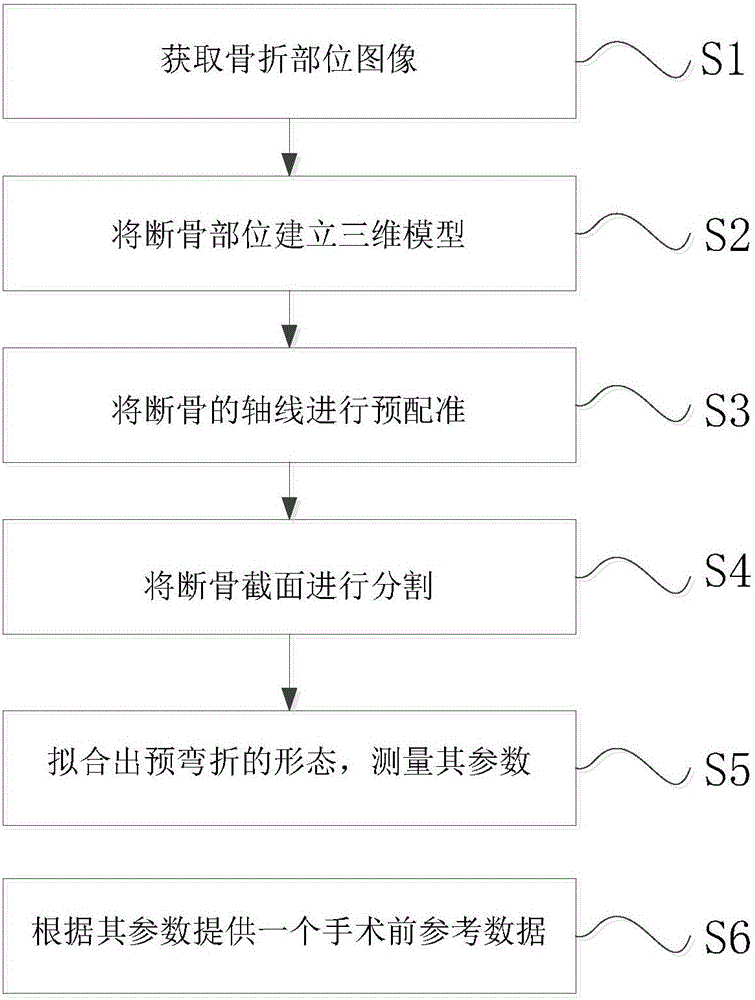

[0041] like figure 1 As shown, the present invention provides a method for digitally simulating the pre-bending of a fracture steel plate, comprising the following steps:

[0042] S1. Obtain an image of the fracture site;

[0043] S2, building a three-dimensional model of the broken bone;

[0044] S3. Pre-register the axis of the broken bone;

[0045] S4. Segment and register the cross-section of the broken bone;

[0046] S5, fitting the shape of the pre-bending, and measuring its parameters;

[0047] S6. Provide a pre-operation reference data according to its parameters.

[0048] This method constructs a three-dimensional image by acquiring images of the fracture site, and then pre-registers the fracture site according to the three-dimensional image, and then accurately registers the cross-section of the broken bone, and drives the registration of the two broken bones, and finally according to the bone model The pre-bending state of the steel plate is fitted by the contr...

Embodiment 2

[0062] In this embodiment, the step S3 includes:

[0063] S31. Extract the axes of the two broken bones for spatial registration;

[0064] S32. Drive the three-dimensional models of the two broken bones to perform pre-registration according to the axes.

[0065] Include the following steps in described S31:

[0066] S311. Extract the axes of the two broken bones;

[0067] S312. Perform a registration operation on the two axes, and simultaneously drive the two broken bones to change their spatial positions, so as to realize pre-registration.

[0068] Because the most basic thing in human organ surgery is accuracy. For fracture surgery, it is required that the broken bones can be spliced together accurately. Because the direct registration method requires a lot of iterative calculations and consumes a lot of time, it is necessary to use coarse The method of combining registration and precise registration realizes the registration of broken bones, and the method of pre-regis...

Embodiment 3

[0071] In this embodiment, the step S4 includes:

[0072] S41. Obtain cross-sections of two broken bones for registration;

[0073] S42. Driving two broken bones to perform model registration.

[0074] Wherein, the step S41 includes:

[0075] S411. Extract feature points of the characteristic fractured bone section;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com