Device and method for precise pressure point of thin-walled tube

A thin-walled tube and precise technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of reducing production efficiency, increasing labor intensity, not popularizing and adopting, etc., to achieve rapid positioning of tooling, improve pressure point efficiency, The effect of high pressure point accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

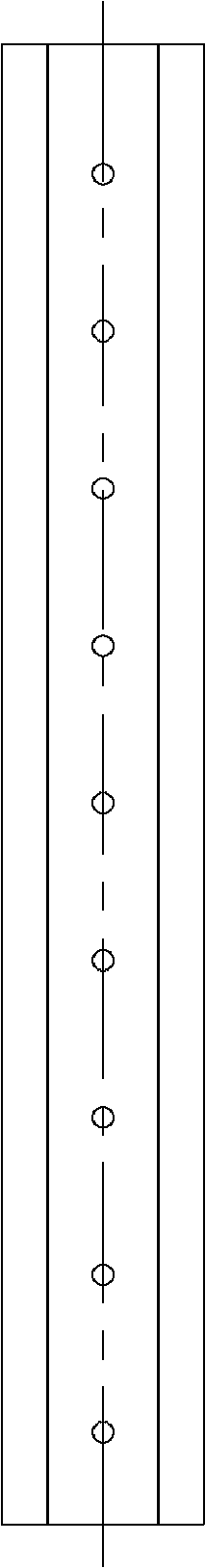

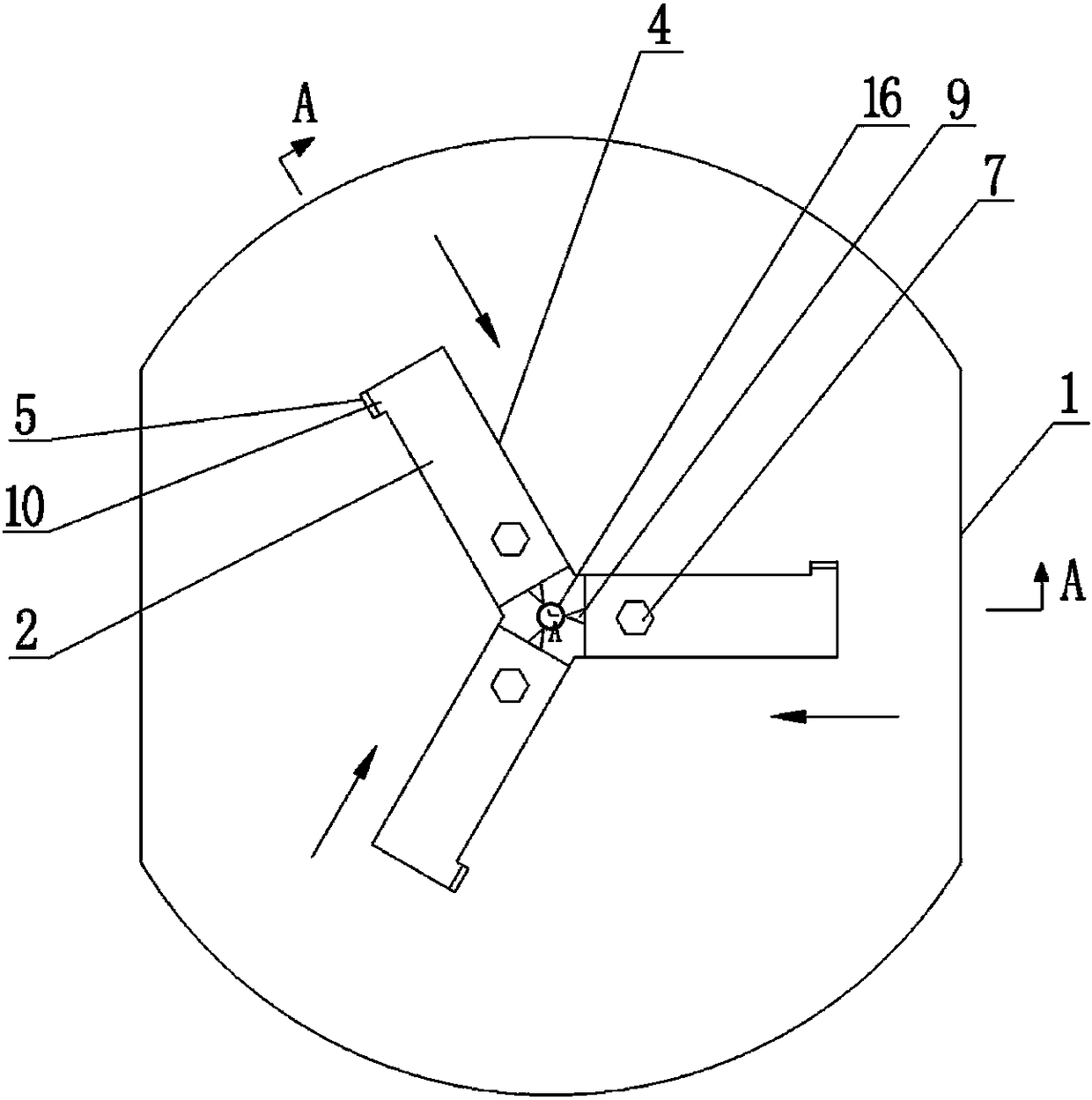

[0022] Such as Figure 3~6 As shown, a thin-walled tube precision pressure point device, which includes a clamp body 1, pressure point bar 2 and hydraulic cylinder 3, the top of the clamp body 1 is evenly distributed with three interconnected chute 4, the The three inclined grooves 4 are arranged in a triangle, and the slopes of the inclined grooves 4 have an inclination angle of 10 to 16°. The side walls of each inclined groove 4 are provided with grooves 5 connecting the inclined grooves 4, and the grooves 5 are arranged along the inclined surfaces.

[0023] Such as Figure 3~6 As shown, the pressure point bar 2 is composed of a pressure point main body 6, an adjusting screw 7, a lifting plate 8 and a conical head 9. One side of the pressure point main body 6 is a slope, and an inclined block 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com