Machining method of pitched roof via hole hanging table

A processing method, the technology of inclined top, applied in the field of injection mold manufacturing, can solve problems such as rework, affecting product quality and production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

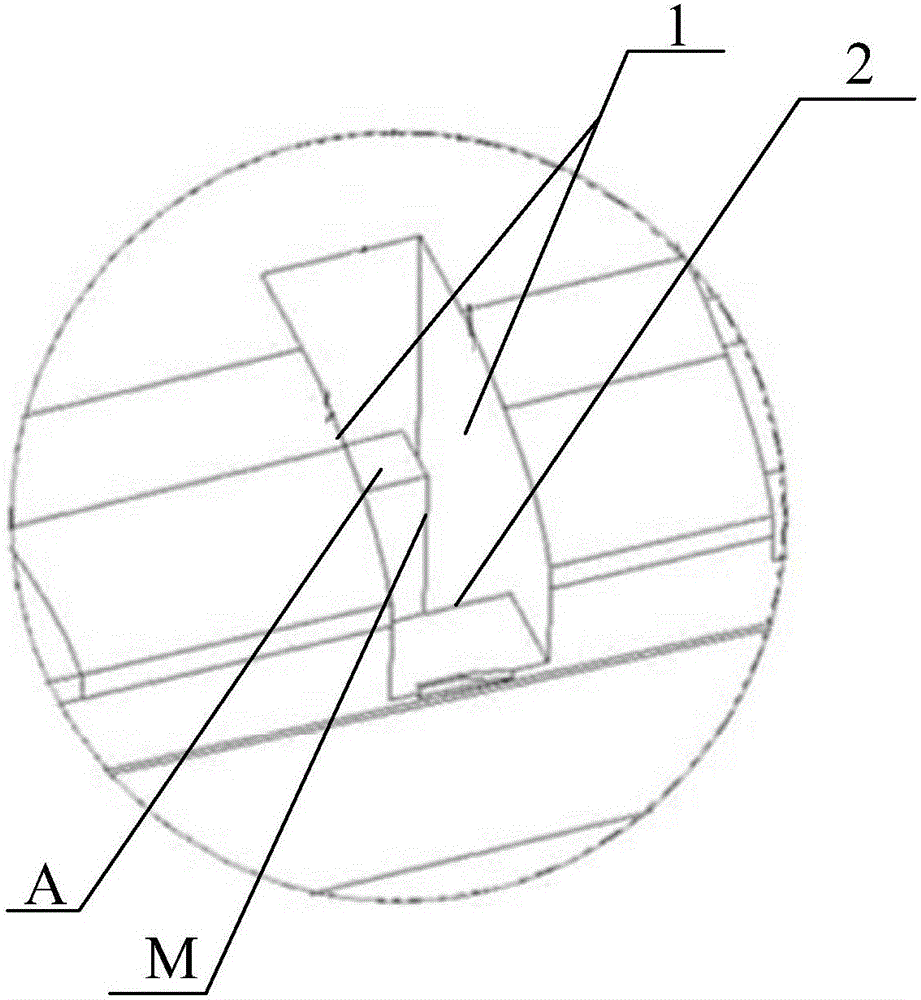

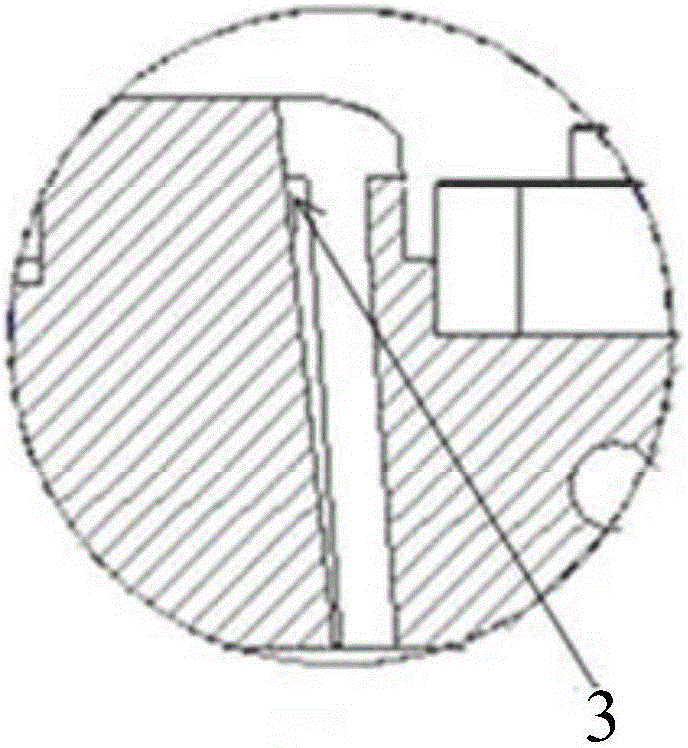

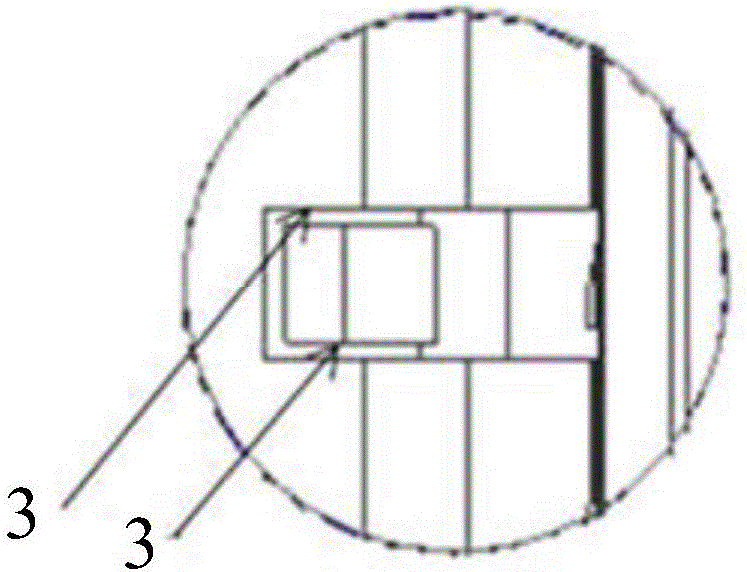

[0016] The core of the present invention is to provide a processing method for a slanted top through-hole hanging platform, so that the combination of the hanging platform and the corner position of the through-hole can be smoothly combined by this processing method, and rework can be avoided.

[0017] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Compared with the traditional processing method, the core improvement point of the processing method of the slanted top via hole hanging table disclosed in the present invention is that a process groove is preset at the two sides of the combination of the hanging table and the via hole, and then the process After the wire is threaded in the slot, the left and right sides of the hanging table are processed by wire-cutting slow-moving te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com