A penetrating tank inner wall flexible polishing device

A polishing device and wall flexible technology, which is applied in the direction of grinding/polishing safety device, grinding drive device, grinding/polishing equipment, etc., can solve the problems of high polishing cost and difficult processing of tank parts, etc., and improve the polishing quality , Easy to manufacture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

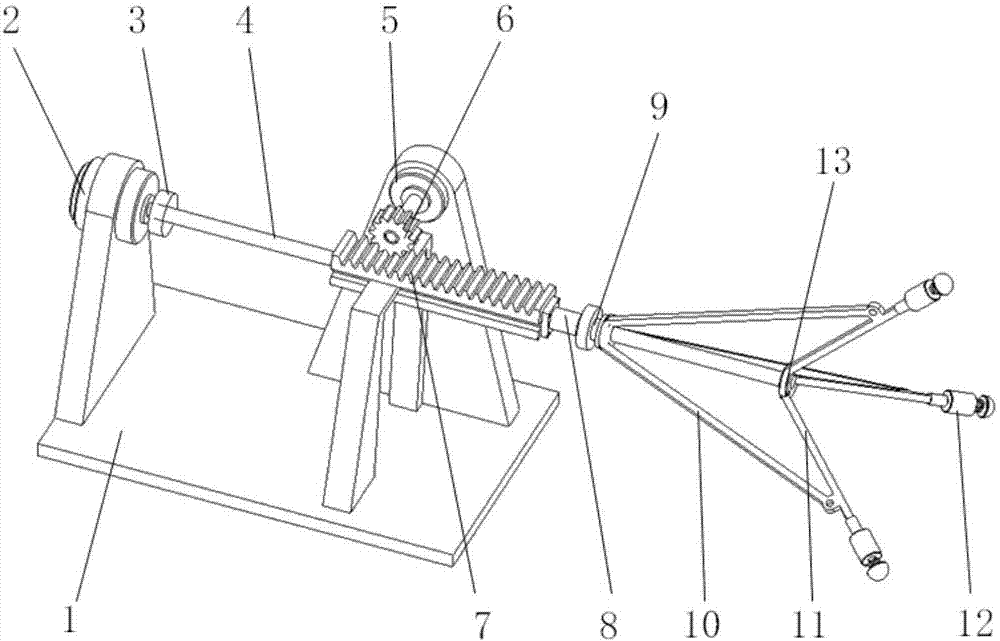

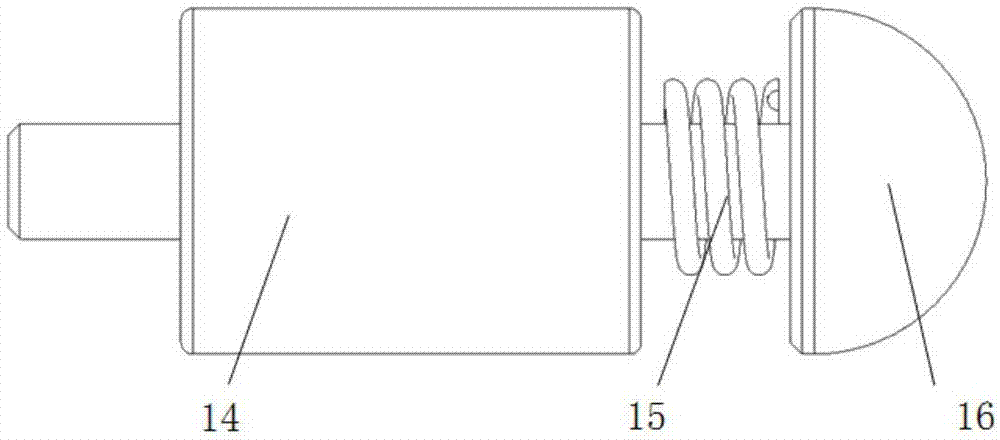

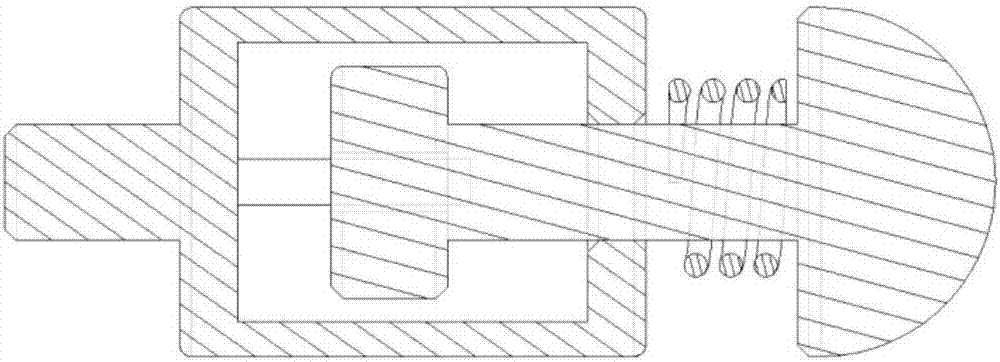

[0025] The penetrating type cylinder inner wall flexible polishing device disclosed by the present invention comprises a support base and a first motor arranged on the support base. The first motor drives the main rotating shaft to rotate, and a movable A slider that slides back and forth along its axial direction; along the axial direction of the main shaft, at least two first connecting rods are arranged at the end of the slider in the circumferential direction, and at the end of the main shaft in the circumferential direction. There are second connecting rods equal in number to the first connecting rods, and a flexible polishing head is connected to the end of each of the second connecting rods; the first connecting rod adjusts the expansion angle of the second connecting rods, while the second connecting rods The two connecting rods rotate under the drive of the main shaft to realize the polishing of the inner wall of the tank with different diameters.

[0026] The polishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com