A kind of alkali residue water-retaining agent and its spray drying preparation method and application

A water-retaining agent and alkali slag technology, applied in the field of building materials, can solve the problems of destroying the internal pore structure of chlor-alkali slag and reducing water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

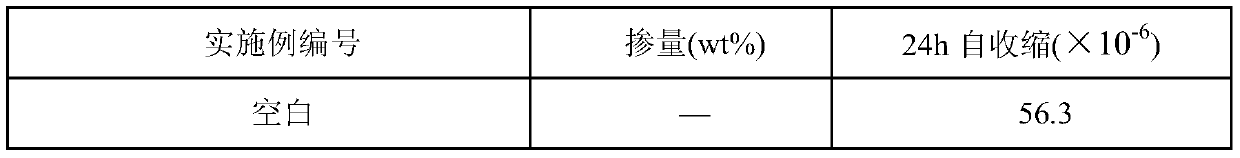

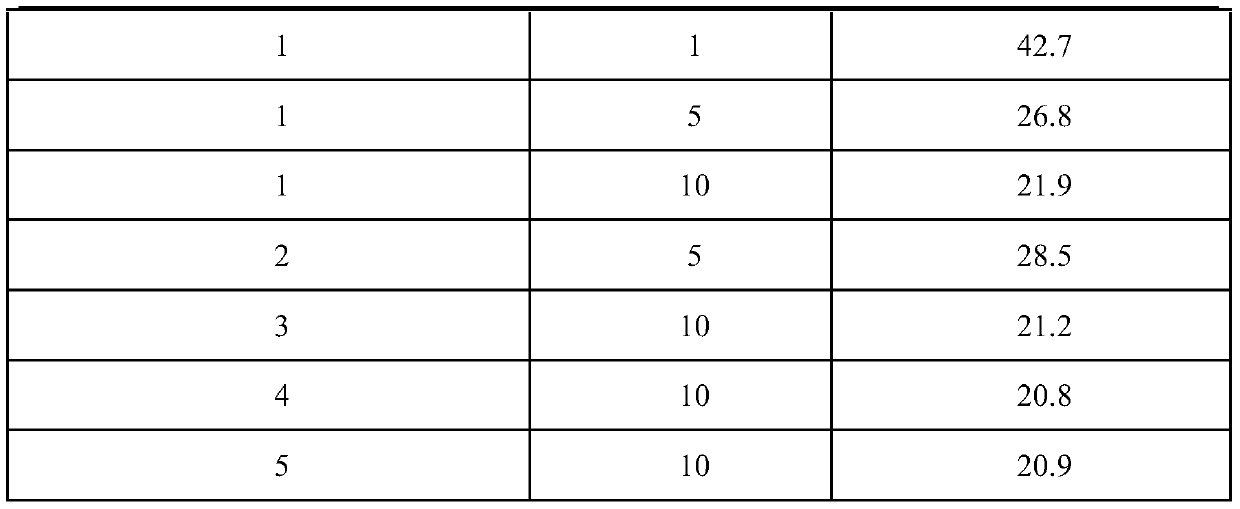

Examples

Embodiment 1

[0026] Preparation of alkali slag water retaining agent by spray drying method and chlor-alkali slag removal:

[0027] 1) Mix the alkali slag and water evenly to obtain a mixture of alkali slag and water, dehydrate the mixture of alkali slag and water, the moisture content after dehydration is 95%, and the obtained chloride ion content is 1.2wt% of the total solid mass in the mixture Chlor-alkali slag;

[0028] 2) adding water to the chlorine-alkali removal slag with the chlorine ion content being 1.2wt% of the total solid mass in the mixture, and fully stirring evenly to make a chlor-alkali removal slag slurry with a solid mass percentage of 20wt%;

[0029] 3) Introduce the chlor-alkali slag slurry into the atomizer, which is a centrifugal atomizer spray drying equipment. The temperature in the drying chamber is controlled at 80° C. to obtain an alkali slag water-retaining agent with a 0.30 mm sieve residue of 4 wt%.

Embodiment 2

[0031] Preparation of alkali slag water retaining agent by spray drying method and chlor-alkali slag removal:

[0032] 1) Mix the alkali slag and water evenly to obtain a mixture of alkali slag and water, dehydrate the mixture of alkali slag and water, the moisture content after dehydration is 96%, and the obtained chloride ion content is 0.9wt% of the total solid mass in the mixture Chlor-alkali slag removal.

[0033] 2) adding water to the chlor-alkali removal slag with the chlorine ion content being 0.9wt% of the total solid mass in the mixture, fully stirring evenly, and making a chlor-alkali removal slag slurry with a solid mass percentage of 30wt%;

[0034] 3) Introduce the chlor-alkali slag slurry into the atomizer, which is a spray drying equipment of air-flow atomizer. The temperature in the drying chamber is controlled at 100° C. to obtain an alkali slag water-retaining agent with a 0.30 mm sieve residue of 8 wt%.

Embodiment 3

[0036] Preparation of alkali slag water retaining agent by spray drying method and chlor-alkali slag removal:

[0037] 1) Mix the alkali slag and water evenly to obtain a mixture of alkali slag and water, dehydrate the mixture of alkali slag and water, the water content after dehydration is 93%, and the content of chloride ions is 0.5wt% of the total solid mass in the mixture Chlor-alkali slag;

[0038] 2) Adding water to the chlor-alkali slag with a chlorine ion content of 0.5wt% of the total solid mass in the mixture, fully stirring evenly, and making a chlor-alkali slag slurry with a solid mass percentage of 40wt%;

[0039] 3) Introduce the chlor-alkali slag slurry into the atomizer, which is a centrifugal atomizer spray drying equipment. The temperature in the drying chamber is controlled at 120° C. to obtain an alkali slag water-retaining agent with a 0.30 mm sieve residue of 7 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com