A kind of super-hydrophobic metal-organic framework composite material and its preparation method and application

A metal-organic framework and super-hydrophobic technology, which is applied in the direction of alkali metal compounds, separation methods, chemical instruments and methods, etc., can solve the problems of fluorine-containing materials such as expensive, toxic, and adverse effects on the environment and human body, and achieve excellent hydrophobicity And the effect of chemical stability, great application prospect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

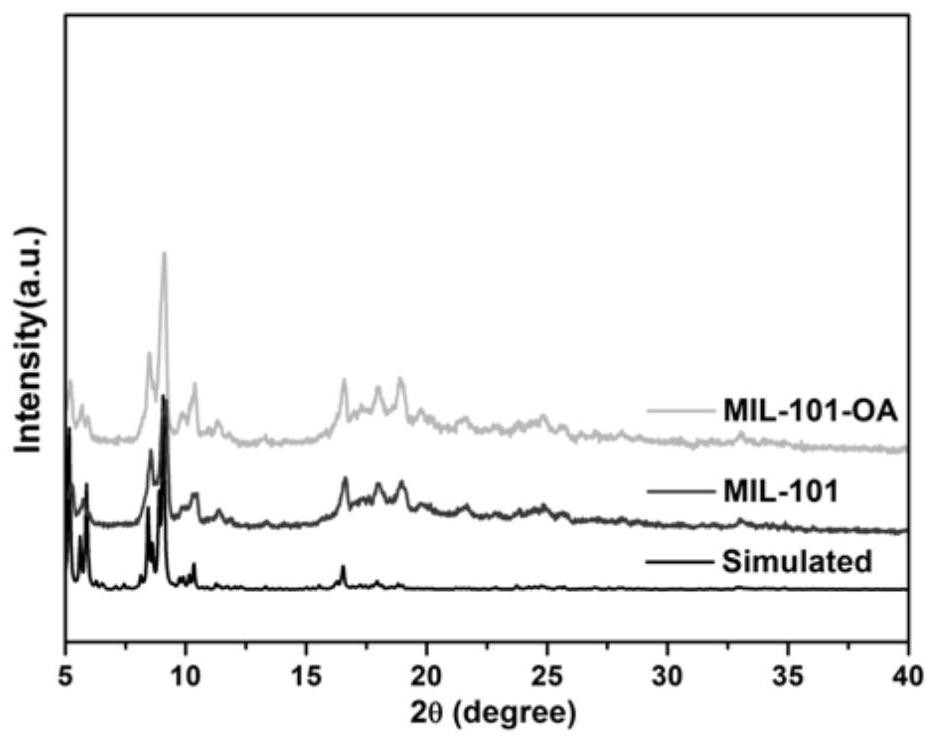

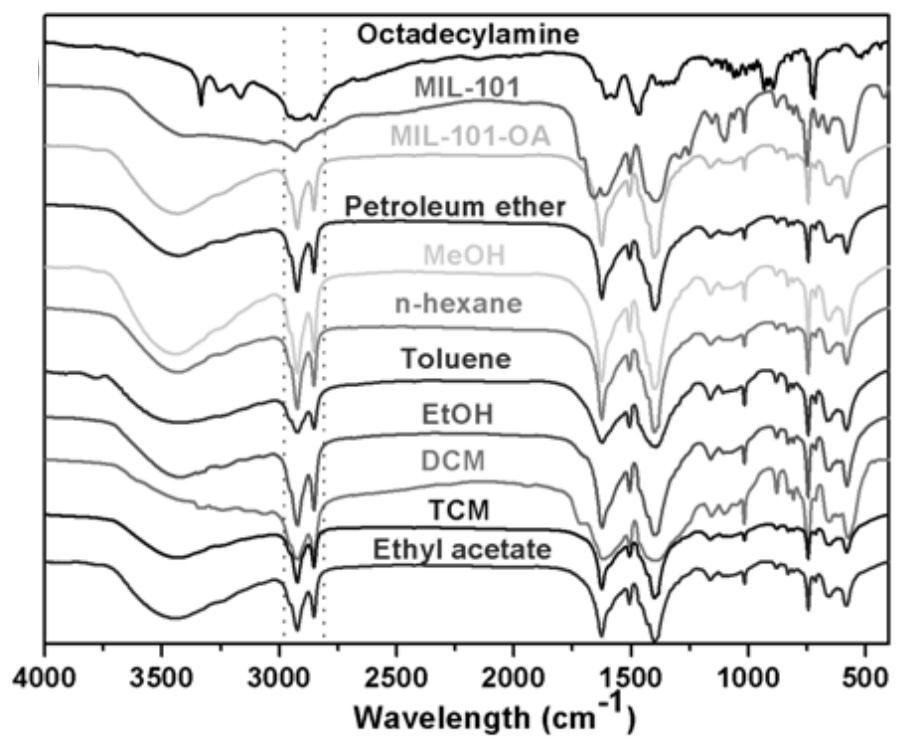

[0032] Example 1 Superhydrophobic metal-organic framework composite material

[0033] (1) The preparation method is as follows

[0034] 1. Preparation of metal-organic framework materials:

[0035] 1) 800mg Cr(NO 3 ) 3 , 328mg of terephthalic acid, 10mL of deionized water and 1.5mL of 36% acetic acid solution were added into a 25mL autoclave, and stirred for 30min at room temperature;

[0036] 2) Seal the autoclave and put it into an oven, heat it to make the temperature of the oven rise from room temperature to 473K, and keep it at this temperature for 24 hours; the heating rate is 5°C·min -1 .

[0037] 3) at 5°C·min -1 The cooling rate was slowly cooled to room temperature and left to stand for 24 hours to obtain a dark green powder, which was centrifuged, and the collected solid was washed with water, N,N-dimethylformamide (DMF), ethanol and methanol in sequence, centrifuged, and dried.

[0038] The obtained metal-organic framework material, which is denoted as MIL-10...

Embodiment 2

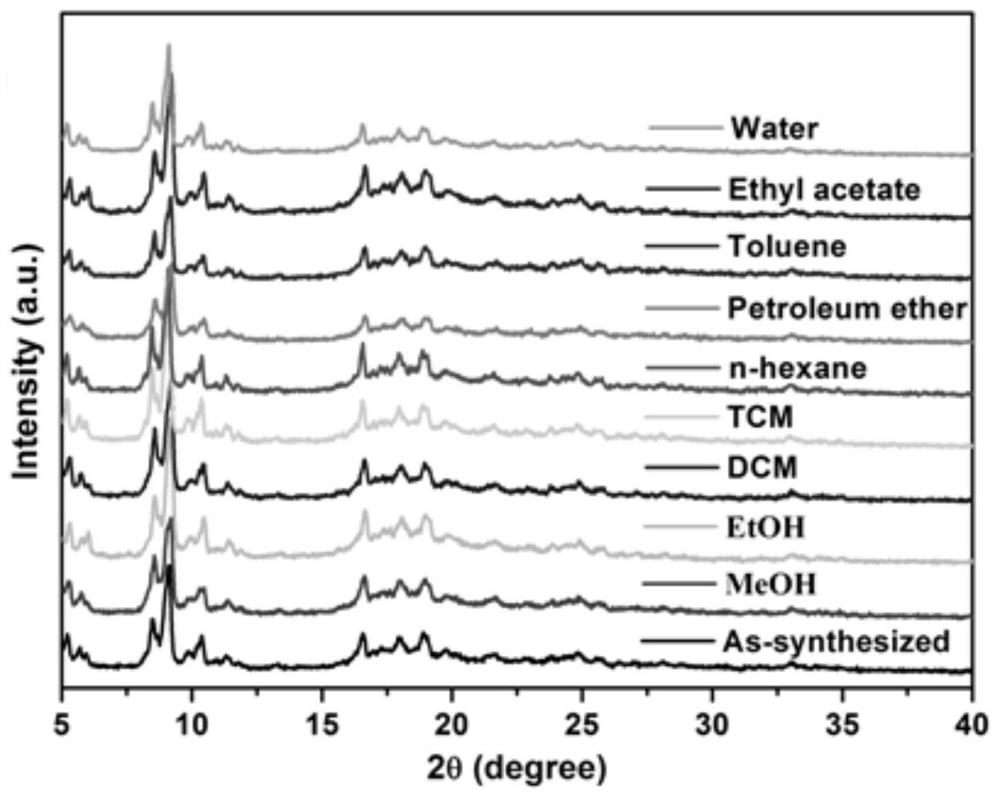

[0050] Example 2 Application of superhydrophobic metal-organic framework composites in oil-water separation

[0051] (1) Oil absorption performance

[0052] Oil-water separation experimental device such as Figure 5 As shown, the oil-water separation experimental device consists of an upper pipeline 1, a lower pipeline 2, a collection device 3, a fixed separation device 4, a superhydrophobic filter paper 5 and an oil-water mixture container 6. The super-hydrophobic filter paper 5 is placed between the upper pipe 1 and the lower pipe 2, and the MIL-101-OA composite material prepared in Example 1 is placed on the super-hydrophobic filter paper 5.

[0053] Preparation of oil-containing dye wastewater: Add 100 mL of chloroform (TCM), n-hexane (n-hexane; Hex), petroleum fans (Petroleum ether; PE) and toluene ( Toluene), respectively configured as oil-water mixed solution.

[0054] Method: Take 200mL of the above-mentioned oil-water mixture solution in the oil-water mixture conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com