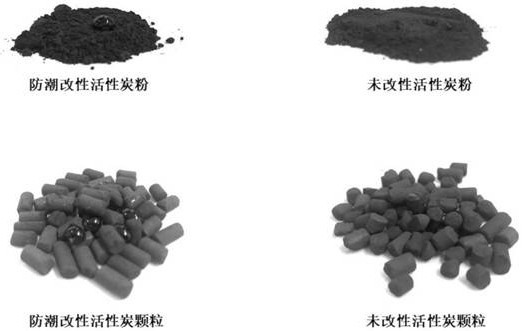

Hydrophobic activated carbon and preparation method thereof

A technology of activated carbon and hydrophobicity, which is applied in the field of preparation of the above-mentioned hydrophobic activated carbon, which can solve the problems of short service life and inability to maintain adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of hydrophobic activated carbon of the present invention specifically comprises the steps:

[0028] (1) heat treatment of powdered or granular activated carbon at 120°C for 10 hours, and set aside;

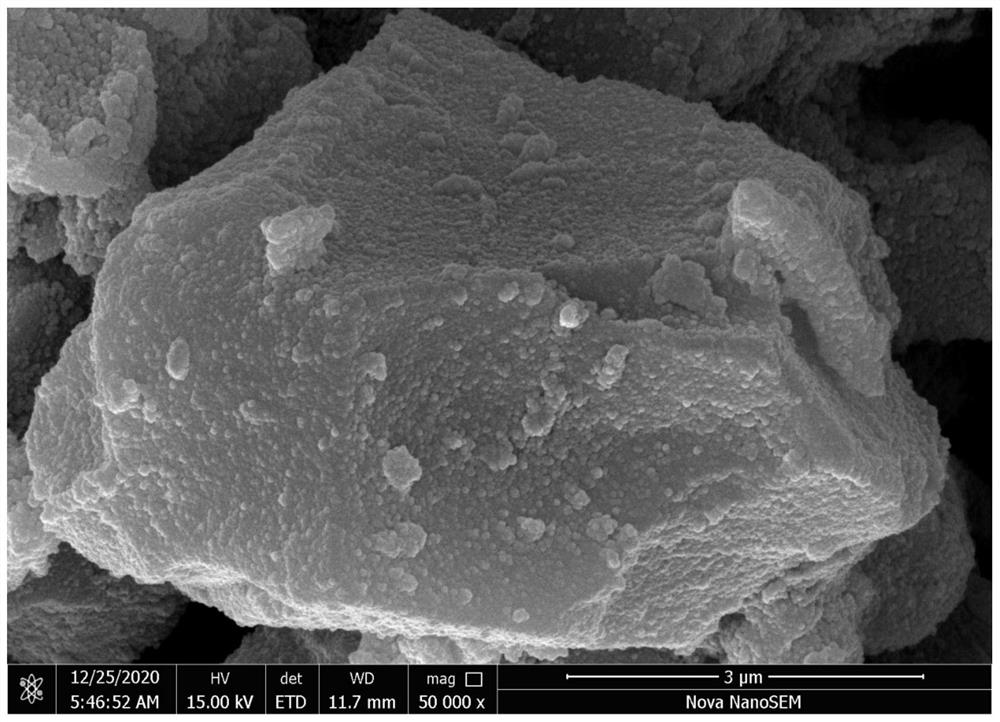

[0029] (2) Use hydrochloric acid to adjust the pH to 8.5 with 500mL tris aqueous solution (in the tris aqueous solution, the concentration of tris is 0.05mol / L), and then add tris to tris Add 500mg of dopamine hydrochloride to the methane aqueous solution, stir magnetically at 30°C for 0.5h, then add 500mg of activated carbon from step (1) to the above solution, obtain a mixed solution after ultrasonic dispersion, continue stirring for 24h, and take out after stirring Activated carbon, after washing, dry at 120°C for 24 hours to obtain activated activated carbon;

[0030] (3) Dissolve 1.2g of 2-methylimidazole in 40mL of alcohol, add 0.06g of activated carbon to it at room temperature, then add an alcoholic solution containing 0.6g of zinc nitrate he...

Embodiment 2

[0034] The preparation method of hydrophobic activated carbon of the present invention specifically comprises the steps:

[0035] (1) heat treatment of powdered or granular activated carbon at 120°C for 8 hours, and set aside;

[0036](2) Use hydrochloric acid to adjust the pH to 7.5 with 500mL tris aqueous solution (in the tris aqueous solution, the concentration of tris is 0.05mol / L), and then add tris to tris Add 100mg of dopamine hydrochloride to the methane aqueous solution, stir magnetically at 30°C for 0.5h, then add 500mg of activated carbon from step (1) to the above solution, obtain a mixed solution after ultrasonic dispersion, continue stirring for 24h, and take out after stirring Activated carbon, after washing, dry at 120°C for 24 hours to obtain activated activated carbon;

[0037] (3) Dissolve 1.2g of 2-methylimidazole in 40mL of alcohol, add 0.06g of activated charcoal to it at room temperature, then add an alcohol solution containing 0.32g of zinc chloride to...

Embodiment 3

[0041] The preparation method of hydrophobic activated carbon of the present invention specifically comprises the steps:

[0042] (1) heat treatment of powdered or granular activated carbon at 120°C for 4 hours, and set aside;

[0043] (2) Use hydrochloric acid to adjust the pH to 11 with 500mL tris aqueous solution (in the tris aqueous solution, the concentration of tris is 0.05mol / L), and then add tris to tris Add 100mg of dopamine hydrochloride to methane aqueous solution, stir magnetically at 30°C for 0.5h, then add 2000mg of activated carbon from step (1) to the above solution, obtain a mixed solution after ultrasonic dispersion, continue stirring for 24h, and take out after stirring Activated carbon, after washing, dry at 120°C for 24 hours to obtain activated activated carbon;

[0044] (3) Dissolve 0.38g 2-ethylimidazole in 40mL alcohol, add 0.12g activated carbon therein at room temperature, then add alcohol solution containing 0.2g zinc hydroxide to obtain a reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

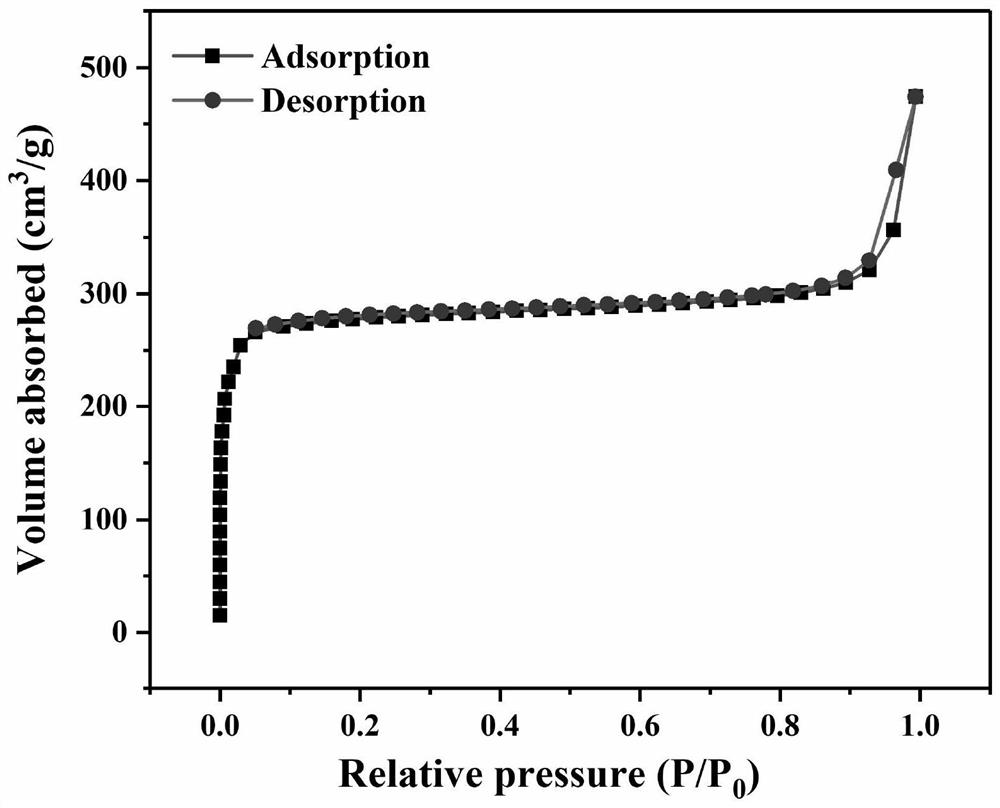

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com