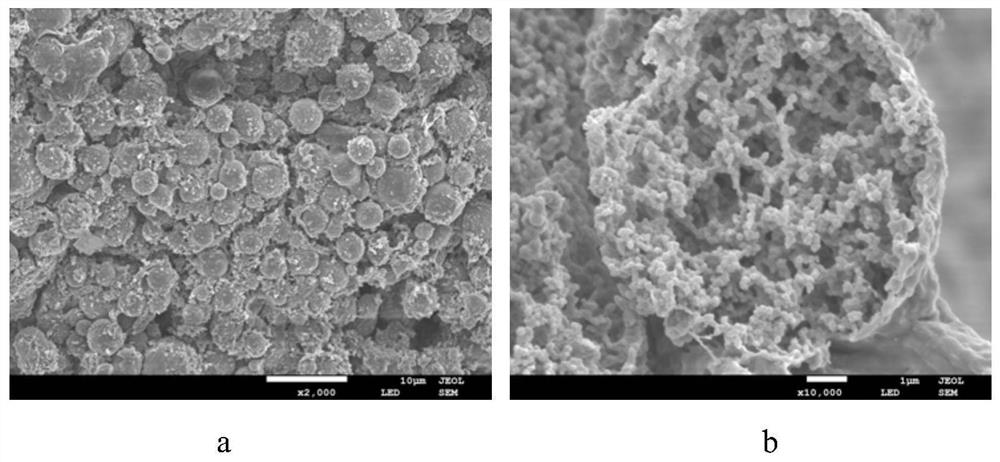

A double-network phase-change airgel and its preparation method

An airgel and double-network technology, applied in the field of materials, can solve the problems of closed pores, limited adsorption capacity, and uneven distribution of phase change materials, etc., to achieve high porosity, simple preparation process, and good immobilization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

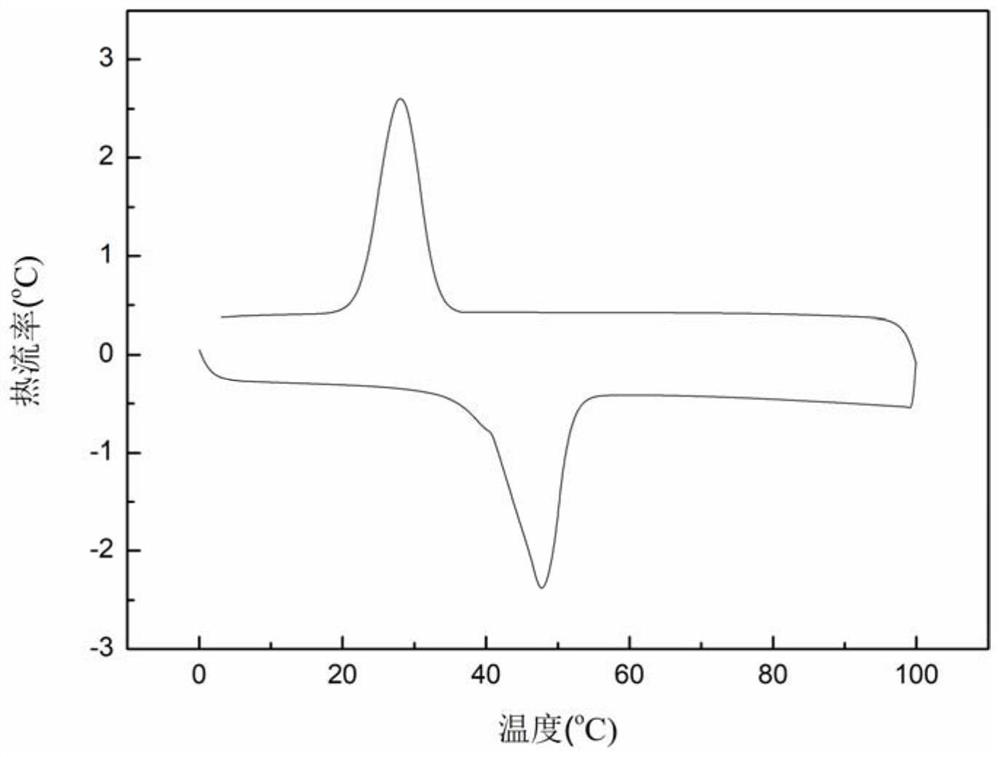

Examples

Embodiment 1

[0040] (1) Preparation of aqueous phase DN solution

[0041] Put 30g of PEG1500 into a 250ml beaker, melt it in a water bath at 60°C, put 90g of water, 1.38g of MBA, 6.58g of AM, 1.38g of SA, and 0.13g of KPS into the melted PEG1500 to form an aqueous phase solution;

[0042] (2) Preparation of oil phase solution

[0043] Weigh 19.5g of emulsifier Span 60, measure 5.6ml of Tween 60, and 332ml of cyclohexane as the dispersed phase, add them into a three-necked flask, dissolve in a water bath at 60°C, and make an emulsion.

[0044] (3) Emulsion polymerization

[0045] Fix the three-necked flask containing the oil phase solution in a water bath at 30°C, extract the water phase solution with a 20ml syringe, adjust the speed of the high-speed disperser to 5400r / min, and feed the water phase solution drop by drop at a speed of 10mm / min. Add it dropwise to a three-necked flask, and continue emulsifying for 30 minutes after the addition. Then set the temperature of the water bath t...

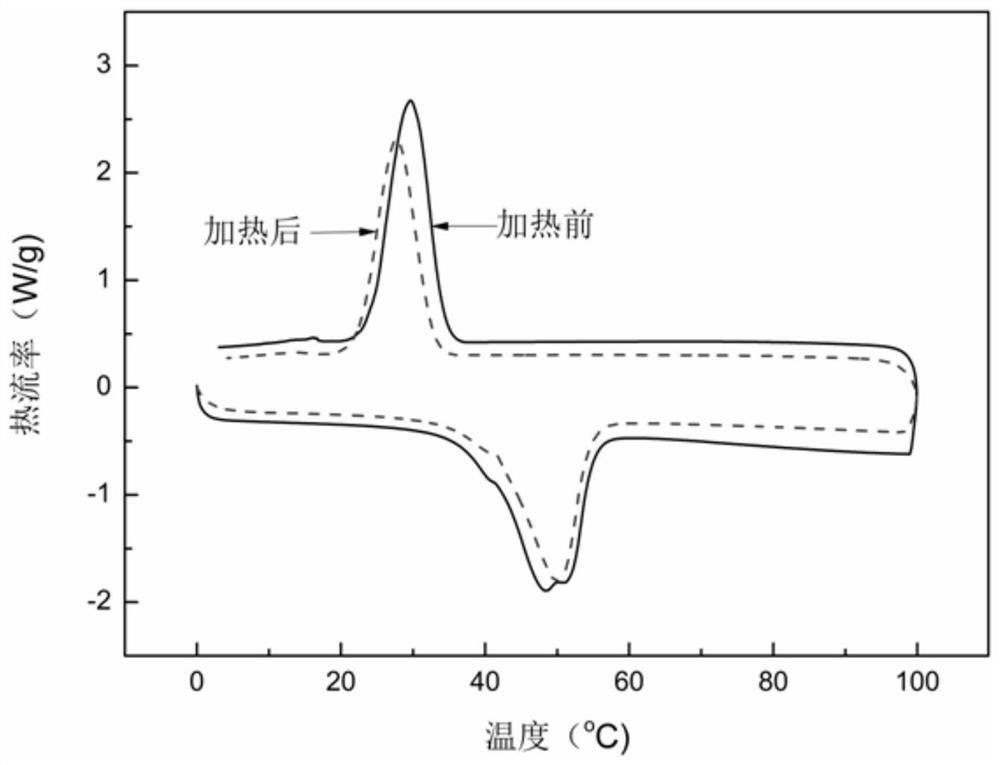

Embodiment 2

[0049] (1) Preparation of aqueous phase DN solution

[0050] Put 30g of PEG1500 into a 250ml beaker, melt it in a water bath at 60°C, put 90g of water, 1.38g of MBA, 6.58g of AM, 1.38g of SA, and 0.13g of KPS into the melted PEG1500 to form an aqueous phase solution;

[0051] (2) Preparation of oil phase solution

[0052] Weigh 19.5g of emulsifier Span 60, measure 5.6ml of Tween 60, and 332ml of dispersed phase cyclohexane, add them into a three-necked flask, dissolve in a water bath at 60°C, and make an emulsion.

[0053] (3) Emulsion polymerization

[0054] Fix the three-necked flask containing the oil phase solution in a water bath at 30°C, extract the water phase solution with a 20ml syringe, adjust the speed of the high-speed disperser to 5400r / min, and feed the water phase solution drop by drop at a speed of 10mm / min. Add it dropwise to a three-necked flask, and continue emulsifying for 30 minutes after the addition. Then set the temperature of the water bath to 75°C,...

Embodiment 3

[0058] (1) Preparation of aqueous phase DN solution

[0059] Put 30g of PEG1500 into a 250ml beaker, melt it in a water bath at 60°C, put 90g of water, 1.38g of MBA, 6.58g of AM, 1.38g of SA, and 0.13g of KPS into the melted PEG1500 to form an aqueous phase solution;

[0060] (2) Preparation of oil phase solution

[0061] Weigh 19.5g of emulsifier Span 60, measure 5.6ml of Tween 60, and 332ml of dispersed phase cyclohexane, add them into a three-necked flask, dissolve in a water bath at 60°C, and make an emulsion.

[0062] (3) Emulsion polymerization

[0063] Fix the three-necked flask containing the oil phase solution in a water bath at 30°C, extract the water phase solution with a 20ml syringe, adjust the speed of the high-speed disperser to 5400r / min, and feed the water phase solution drop by drop at a speed of 10mm / min. Add it dropwise to a three-necked flask, and continue emulsifying for 30 minutes after the addition. Then set the temperature of the water bath to 75°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com