Curable resin composition, article, and method for fabricating the same

A technology for hardening resins and shaped products, which is applied in the field of hardened shaped products and hardenable resin compositions, and can solve the problems of low pyrolysis temperature, high curing temperature, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0022] 100 parts by weight of IC 231 (a silicone resin with an alkoxy content of 0-20%, manufactured and sold by Wacker Chemie AG), 100 parts by weight of IC 836 (organic silicon resin, manufactured and sold by Wacker Chemie AG), and 33 parts by weight of KBM-13 (silane, manufactured and sold by Shin-Etsu Chemical Industry) were added to a reaction bottle and mixed uniformly to obtain siloxane resin LCY 2.

Embodiment 1

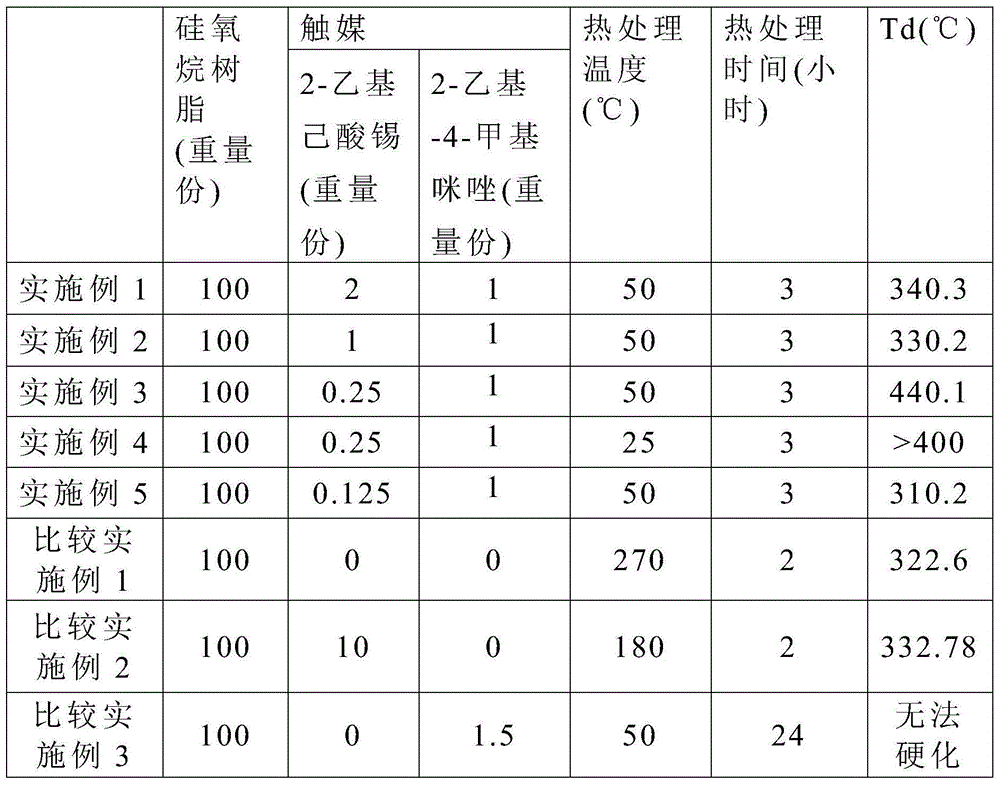

[0024] 2 parts by weight of tin (tin(II) 2-ethylhexanoate) (manufactured and sold by Alfa Aesar) and 1 part by weight of 2-ethyl-4-methylimidazole (2-ethyl-4 -methylimidazole) (the product number is EMI-24, manufactured and sold by T.C.I.) was added to a reaction bottle, and tetrahydrofuran (tetrahydrofuran, THF) was added as a solvent. Next, after fully stirring, 100 parts by weight of silicone resin LCY 2 was added into the reaction flask. After sufficient stirring, resin composition (I) was obtained. Forming the resin composition (I) into a coating and performing a heat treatment on the coating, wherein the process temperature of the heat treatment is 50°C. The coating formed from the resin composition (I) was completely cured within 3 hours to obtain a cured product. Next, the thermal decomposition temperature (thermal decomposition temperature, Td) of the hardened product was measured, and the results are shown in Table 1.

Embodiment 2

[0026] 1 part by weight of 2-ethylhexanoate tin (tin(II) 2-ethylhexanoate) (manufactured and sold by Alfa Aesar) and 1 part by weight of 2-ethyl-4-methylimidazole (2-ethyl-4 -methylimidazole) (product number is EMI-24, manufactured and sold by T.C.I) was added to a reaction bottle, and tetrahydrofuran (tetrahydrofuran, THF) was added as a solvent. Next, after fully stirring, 100 parts by weight of silicone resin LCY 2 was added into the reaction flask. After fully stirring, the resin composition (II) is obtained, the resin composition (II) is formed into a coating, and the coating is subjected to a heat treatment, wherein the heat treatment process temperature is 50°C. The coating layer formed from the resin composition (II) was completely cured within 3 hours to obtain a cured product. Next, the thermal decomposition temperature (thermal decomposition temperature, Td) of the hardened product was measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cracking temperature | aaaaa | aaaaa |

| cracking temperature | aaaaa | aaaaa |

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com