Lubricant for use in press working of a metal material and a press working method of a metal material using the same

A technology of metal materials and lubricants, applied in the direction of additives, lubricating compositions, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

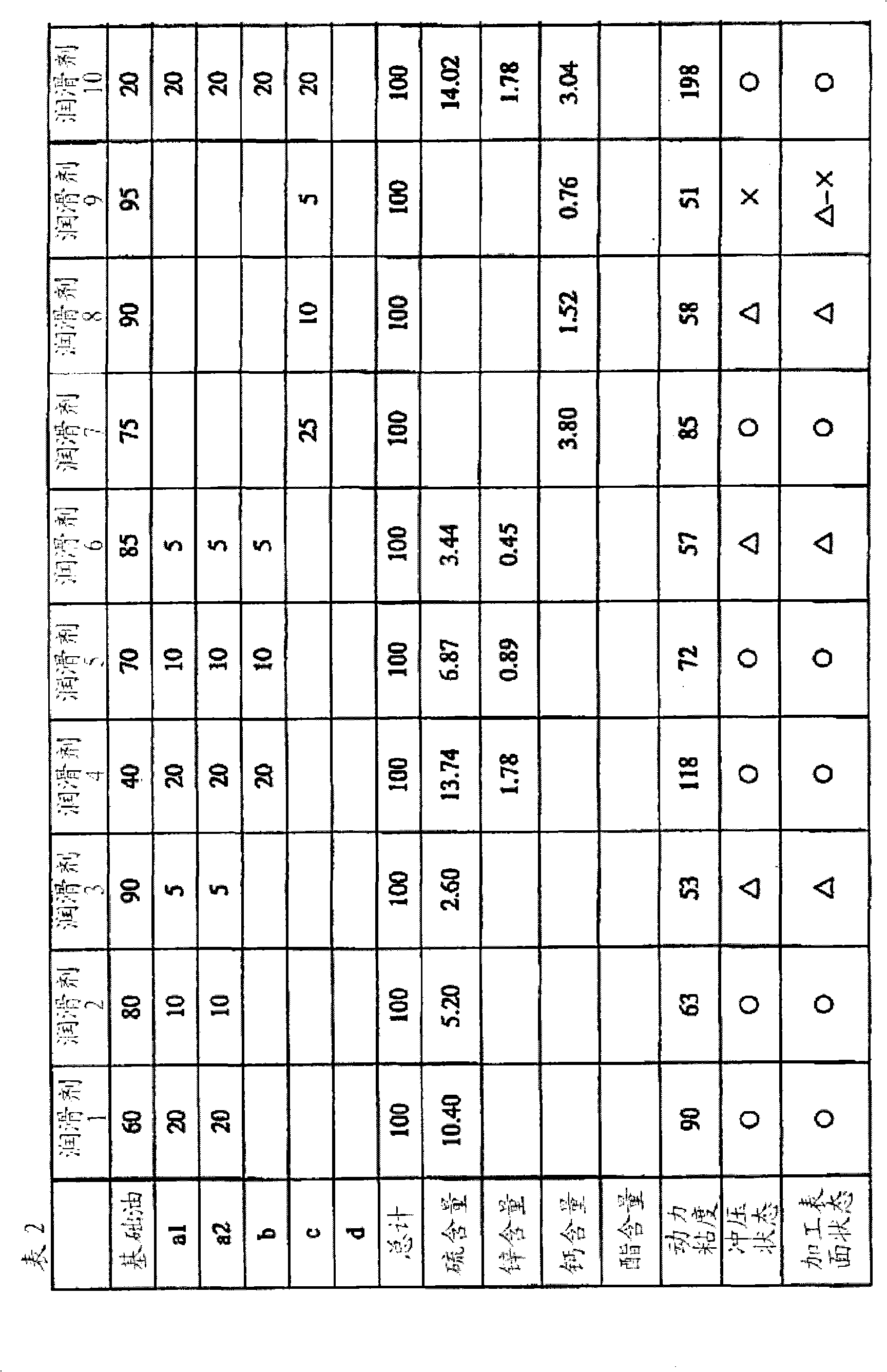

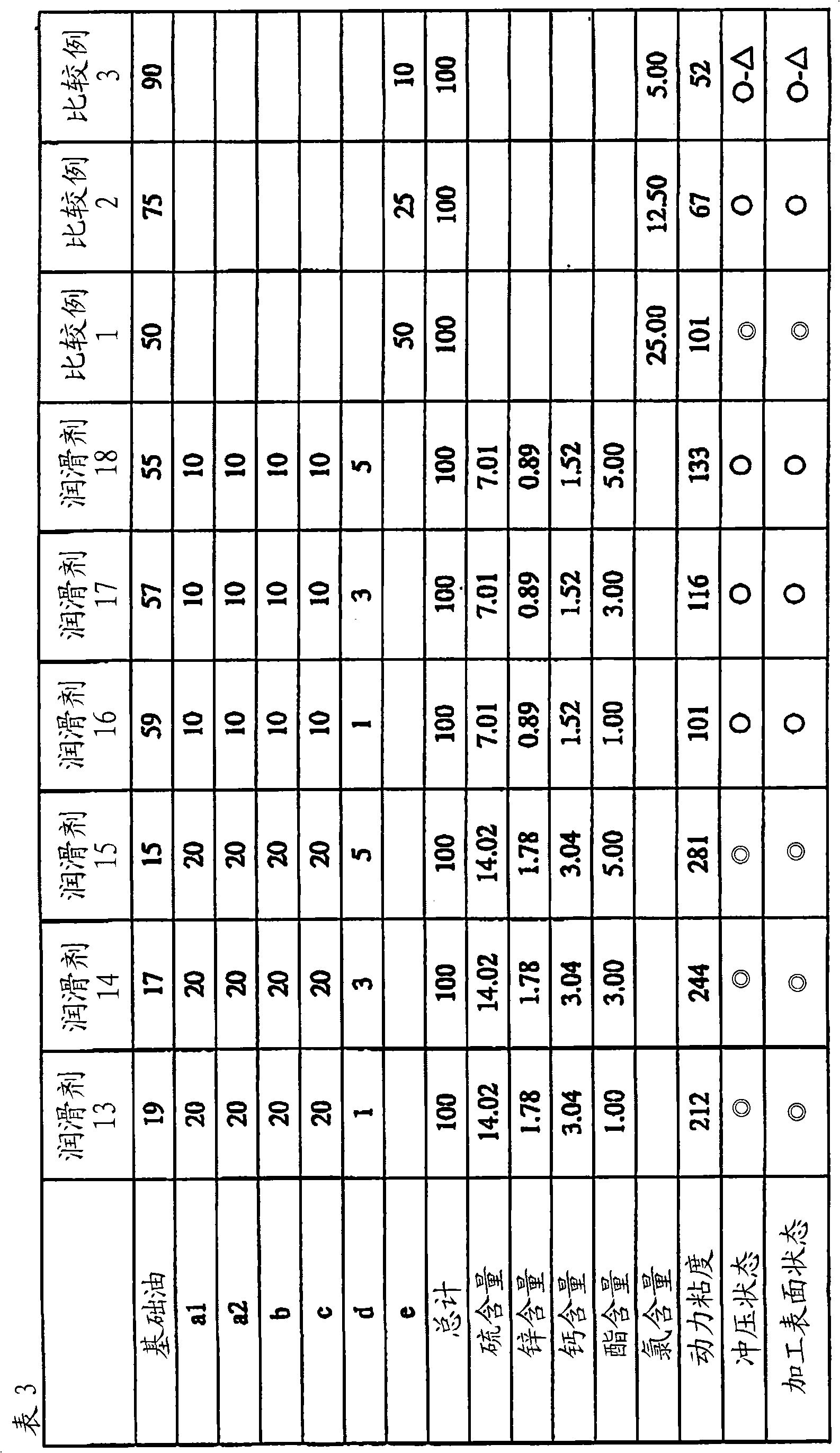

Examples

Embodiment Construction

[0009] The base oil used for the lubricant is not particularly limited, as long as it is generally used as a base oil for metal working oil, and one or more components selected from mineral oil, synthetic oil, and grease may be used. As the mineral oil, those purified by using a conventional method in the lubricant production process of the petroleum purification industry can be used. Specifically, it includes the purification of crude oil by applying one or more processes such as solvent deasphaltization, solvent extraction, hydrogenolysis, solvent dewaxing, catalytic dewaxing, hydrogenation purification, sulfuric acid cleaning, and clay treatment. Those formed from the lubricant fraction obtained by atmospheric distillation or vacuum distillation.

[0010] Synthetic oils include, for example, poly-α-olefins, α-olefin copolymers, polybutenes, alkylbenzenes, polyoxyalkylene glycols, polyoxyalkylene glycol ethers, and Silicone oil. Specific examples of fats and oils include, for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com