Preparation method and application of a lactobacillus fermentum suitable for vinegar brewing and its bacterial powder

A technology for Lactobacillus fermentum and bacteria powder, applied in the field of preparation of Lactobacillus fermentum and bacteria powder, can solve the problems of difficult storage, high transportation cost of liquid lactic acid bacteria, easy to contaminate bacteria, etc. The effect of transportation and content enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Isolation and identification of lactic acid bacteria.

[0051] 1. Isolation and purification of lactic acid bacteria

[0052]Take a 25g sample of Zhenjiang balsamic vinegar fermented grains, add it to 225ml sterile saline and shake it evenly. Take 1ml of the sample and add it to 9ml of sterile normal saline, mix evenly on a vortex mixer, then take 1ml of the diluted solution and add it to 9ml of normal saline, and so on. Select 3 suitable concentrations and apply them sequentially on the MRS solid plate added with calcium carbonate (15-20g / L), and culture in an anaerobic incubator at 37°C for 48h.

[0053] Pick the suspected lactic acid bacteria colony with a large calcium dissolution zone, streak and purify it twice on the MRS plate by streaking method, and store it in a refrigerator at 4°C.

[0054] 2. Primary screening of strains

[0055] Inoculate the preserved strain into a test tube containing liquid MRS medium, seal it with gauze and culture it i...

Embodiment 2

[0075] Example 2: Preparation of Lactobacillus fermentum HS3-7 direct injection bacterial powder.

[0076] 1. Expansion of strains

[0077] Preparation of primary seed liquid: Inoculate purified Lactobacillus fermentum HS3-7 into liquid MRS medium according to 5% inoculum amount, and culture at 37° C. for 20 h.

[0078] Preparation of the secondary seed liquid: select a 50L liquid fermenter, add 35L of processed rice milk, the content of rice flour in the rice milk is 15% to 25%, the processing process of the rice milk is as follows: gelatinize at 100°C for 30 minutes, add 6 ~8u / ml of amylase is kept at 85~90°C for liquefaction for 30 minutes, then 100~300u / ml of glucoamylase is added and kept at 55~60°C for saccharification for 30 minutes. After adding 2‰ skimmed milk powder, sterilize at 115°C for 20min. According to the inoculum amount of 5%, add the primary seed solution. The temperature is controlled at 37°C, the pressure in the tank is 0.05MPa, the pH value of the cul...

Embodiment 3

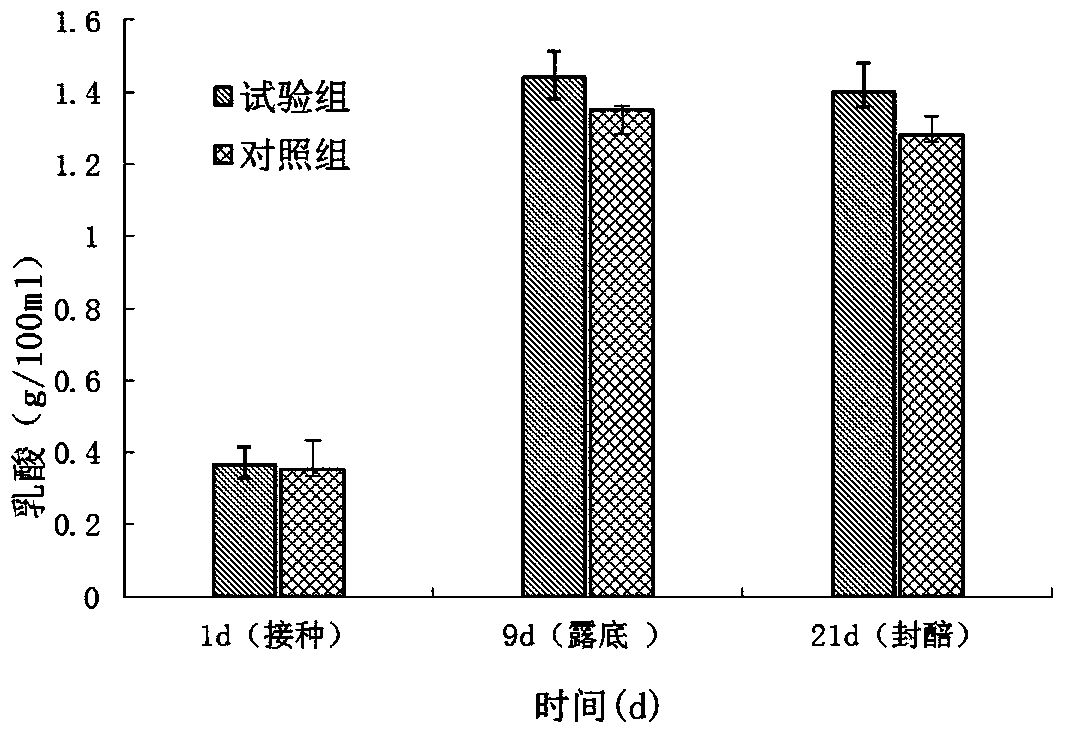

[0085] Example 3: Application of Lactobacillus fermentum HS3-7 direct injection bacterial powder in Zhenjiang vinegar.

[0086] 1. Inoculation and fermentation of direct injection bacterial powder

[0087] Select six 400kg vats, add 250kg of wine mash, 90kg of bran, and 50kg of bran into each vat. Select 3 cylinders as the test group, insert 100g of bacterial powder into each cylinder, and the remaining 3 cylinders as the control group. According to the brewing process of Zhenjiang balsamic vinegar, the seeds are carried out, and the fermented grains are turned over for fermentation.

[0088] 2. Detection of lactic acid content

[0089] During the fermentation process, the bittern after inoculation, when the bottom was exposed and when the fermented grains were sealed were taken for detection.

[0090] Lactic acid adopts high-performance liquid chromatography, referring to the method in Appendix B of "GB / T 18623-2011 Geographical Indication Products Zhenjiang Fragrant Vineg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com