Corrosion method for depletion layer on surface of high-temperature alloy blade

A technology for superalloys and blades, applied in the field of metallographic microstructure detection, can solve problems such as poor reliability, and achieve the effect of optimizing manufacturing parameters and improving the level of microstructure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

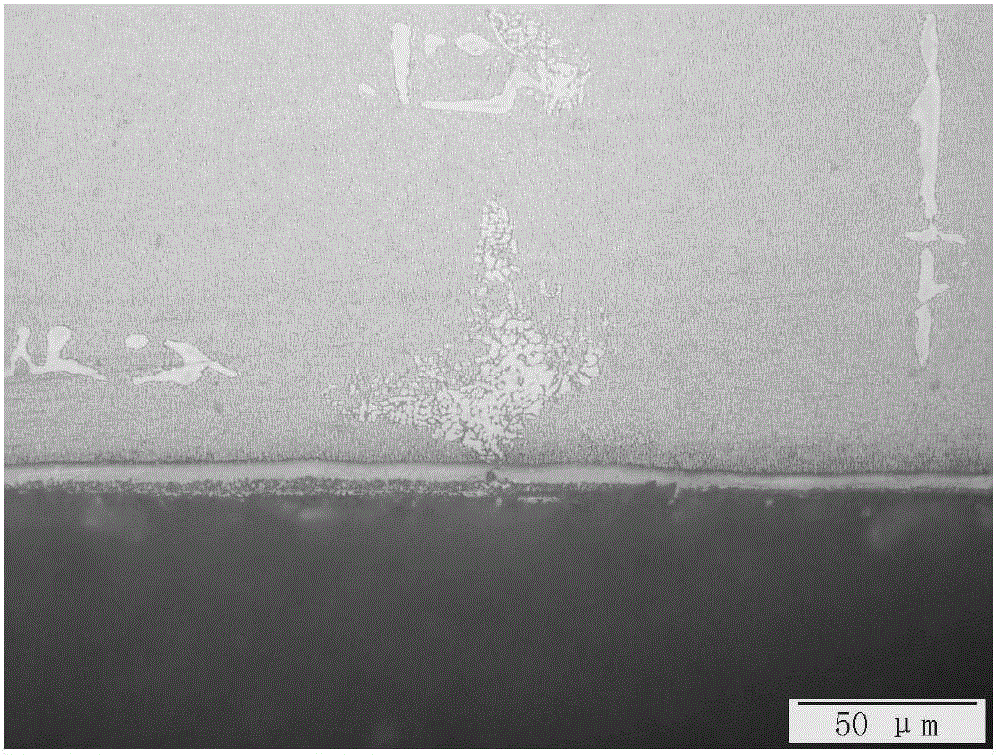

[0036] After the DZ125 high-temperature alloy blade is heat-treated, the middle part of the blade is selected to detect the surface depletion layer. After the surface to be tested is mechanically ground and polished, it is placed in a solution containing a corrosive agent. The volume ratio of oxalic acid and pure water in the corrosive agent = At 10:90, electrolytic corrosion is carried out, and the corrosion parameters are: the voltage is 1.5V, the current is 0.5A, and the time is 10s. Observed under a metallographic optical microscope, the corrosion effect can be seen figure 1 , it was found that the depleted layer on the surface of the DZ125 superalloy blade was clearly visible, and the corrosion effect was obvious.

Embodiment 2

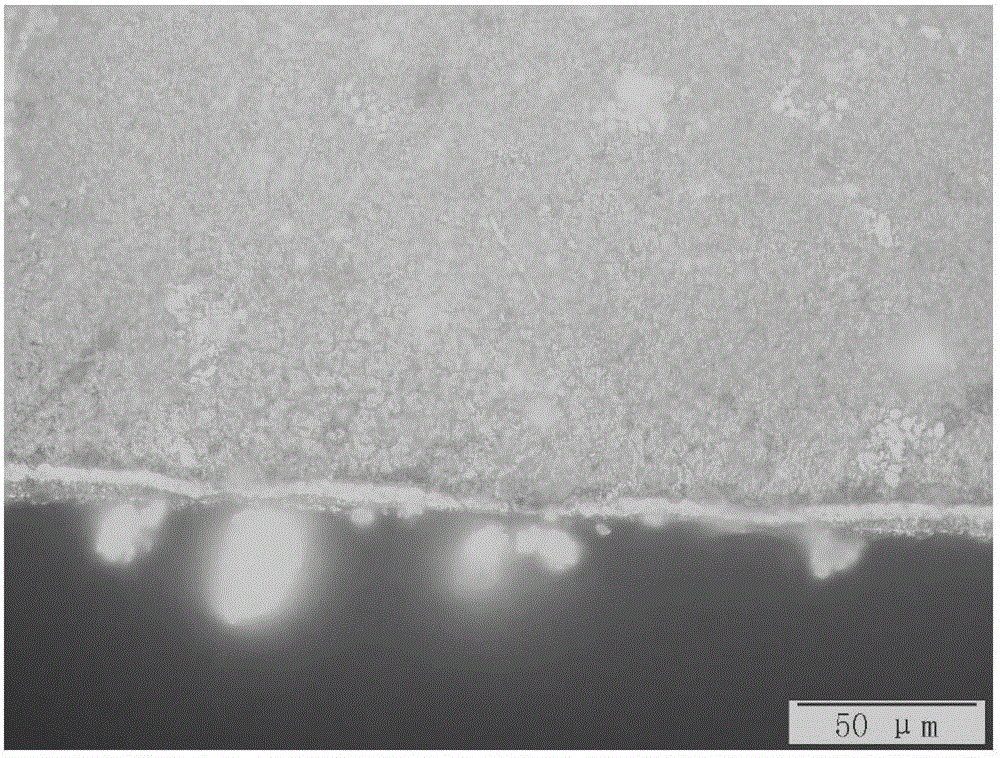

[0038]After the DZ125 high-temperature alloy blade is heat-treated, the middle part of the blade is selected to detect the surface depletion layer. After the surface to be tested is mechanically ground and polished, it is placed in a solution containing a corrosive agent. The volume ratio of oxalic acid and pure water in the corrosive agent = At 20:80, electrolytic corrosion was carried out, and the corrosion parameters were: voltage 1.5V, current 0.5A, and time 10s. Observed under a metallographic optical microscope, the corrosion effect can be seen figure 2 , found that the depletion layer on the surface of the DZ125 superalloy blade is clearly visible, and the corrosion effect is obvious.

Embodiment 3

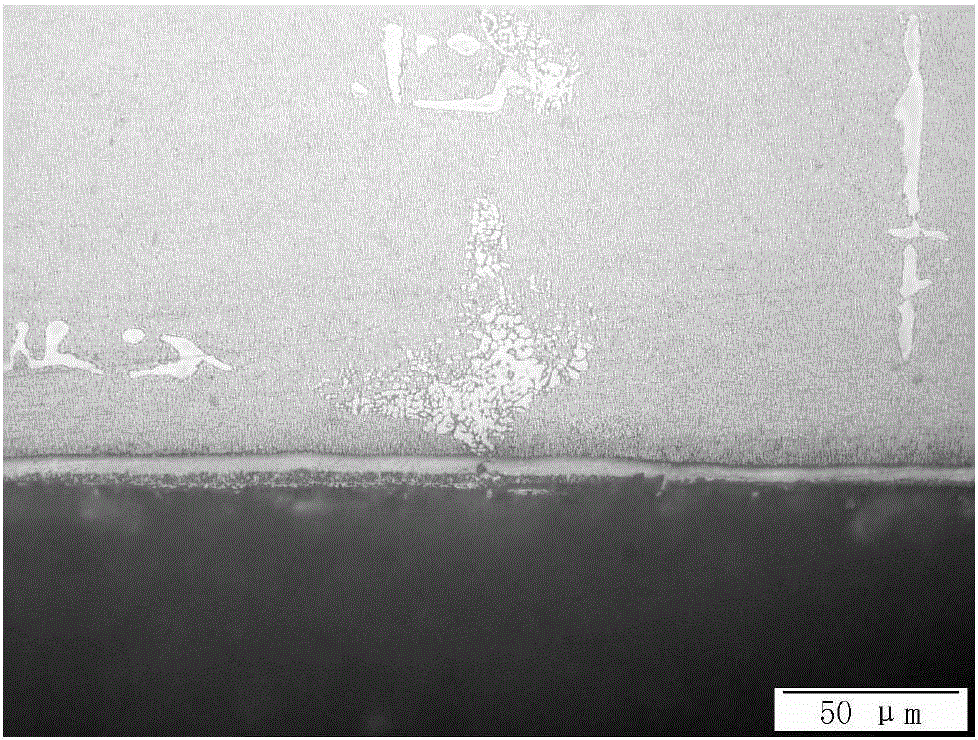

[0040] After the DZ125 high-temperature alloy blade is heat-treated, the middle part of the blade is selected for the detection of the surface depletion layer. After the surface to be tested is mechanically ground and polished, it is placed in a solution containing a corrosive agent. The oxalic acid in the corrosive agent: H 2 O volume ratio = 10:90, electrolytic corrosion, corrosion parameters: voltage 1.5V, current 0.5A, time 5s. Observed under a metallographic optical microscope, the corrosion effect can be seen image 3 , found that the depletion layer on the surface of the DZ125 superalloy blade is clearly visible, and the corrosion effect is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com