Forging method for ultra-large titanium alloy whole frame forged piece

A titanium alloy and ultra-large technology, applied in the field of forging, can solve the problems that the uniformity of mechanical properties of forgings cannot meet the design requirements, the quality of metallurgy cannot be guaranteed, and the difficulty of smelting raw materials, etc., to achieve good uniformity of mechanical properties , processing deformation is small, the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

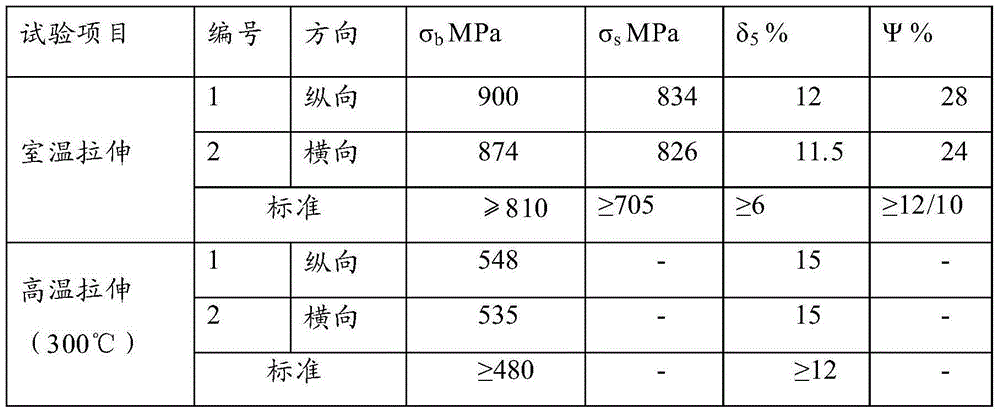

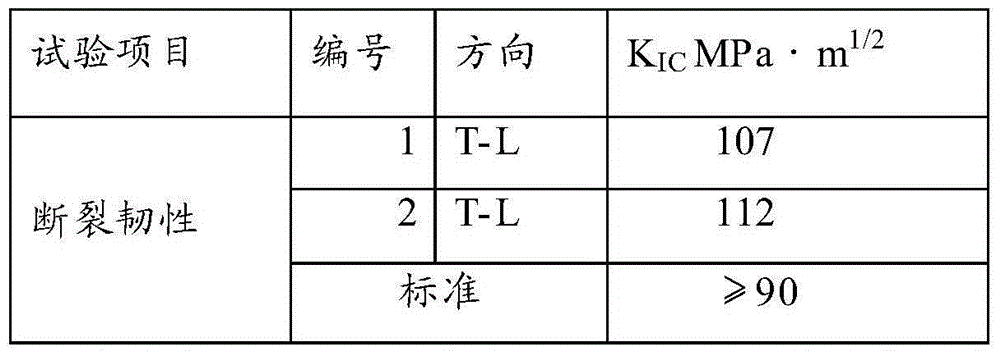

Embodiment 1

[0043] Example 1: forging material: TC4-DT; phase transition point: 985°C; forging outline size: 3700×1830×207mm; forging projected area 5.4m2; forging weight: 1100Kg; The corners corresponding to the blanks are useless materials.

[0044] 1. Blank making

[0045] Step 1, according to the shape and size requirements of the forging, the initial blank is prepared by a local upsetting method.

[0046] The size of the blank for this forging is 2400×1200×160mm. One side of the forging in the width direction is missing a corner, and the corner of the corresponding blank is useless. Therefore, it is necessary to locally upset the corner of the corresponding blank to obtain the initial blank. The specific method is: place the billet in the effective area of a Class III electric furnace for heating, the heating temperature is 950±10°C, and the holding time is 130min; the preheating temperature of the tooling and upper and lower anvils is 100-350°C; the billet is placed on the free f...

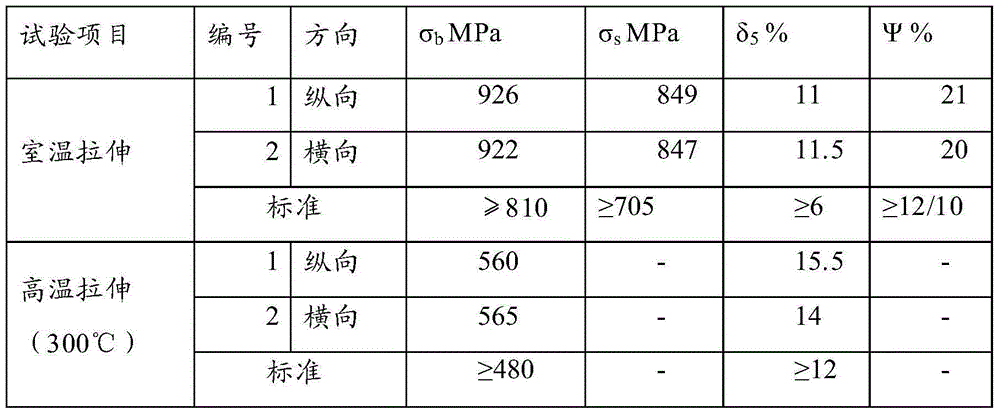

Embodiment 2

[0060] Example 2: forging material: TC4-DT; phase transition point: 982°C; forging outline size: 3705×1784×150mm; forging projected area 5.2m 2 ;Forging weight: 980Kg; One side of the forging in the width direction is missing corners, and the corners corresponding to the blanks are useless materials.

[0061] 1. Blank making

[0062] Step 1, according to the shape and size requirements of the forging, the initial blank is prepared by machining.

[0063] The size of the blank for this forging is 2600×1350×130mm. Due to the thin thickness of the slab, it is more appropriate to remove the excess corner material directly by machining. The length of the two right-angled sides of the removed triangular blank is 300mm.

[0064] Step 2: Place the initial billet in the effective area of a Class III electric furnace for heating, the heating temperature is 947±10°C, and the holding time is 80 minutes; the preheating temperature of the tooling and upper and lower anvils is 100-350°C; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com