Wire outlet structure applied to corrugated lamp

A technology of corrugated lamps and wires, which is applied to the parts of lighting devices, lighting devices, outdoor lighting, etc. It can solve the problems of decreased waterproof effect, poor waterproof performance, loose waterproof wire fixers, etc., and achieves beautiful appearance and good waterproof effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

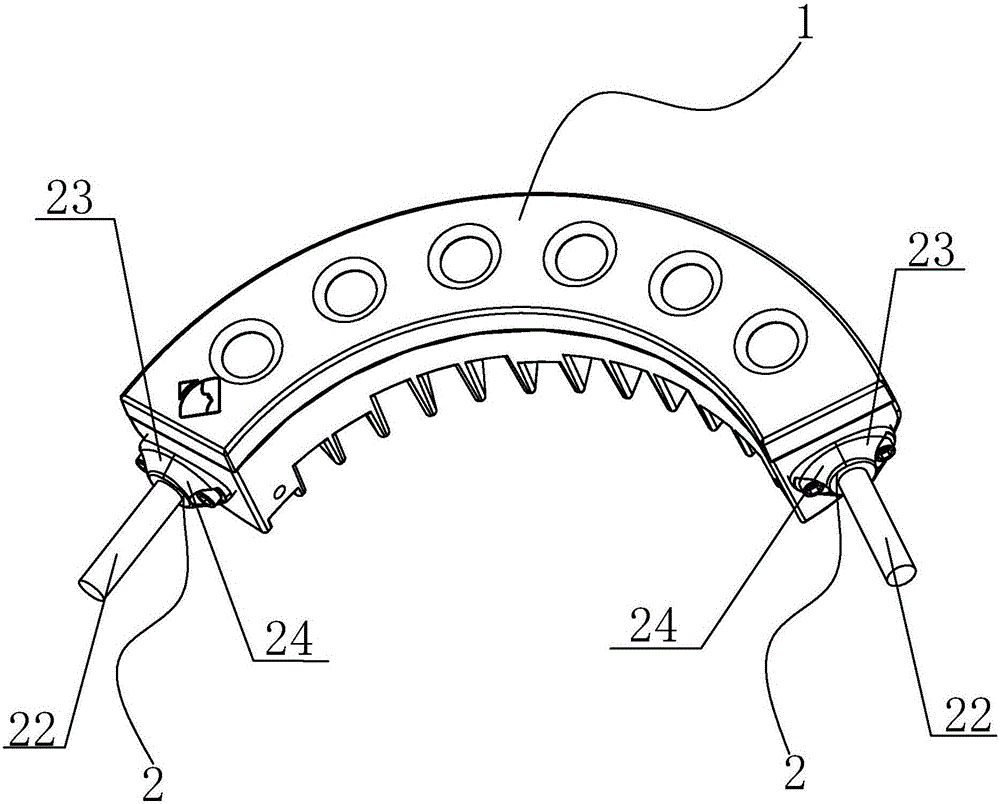

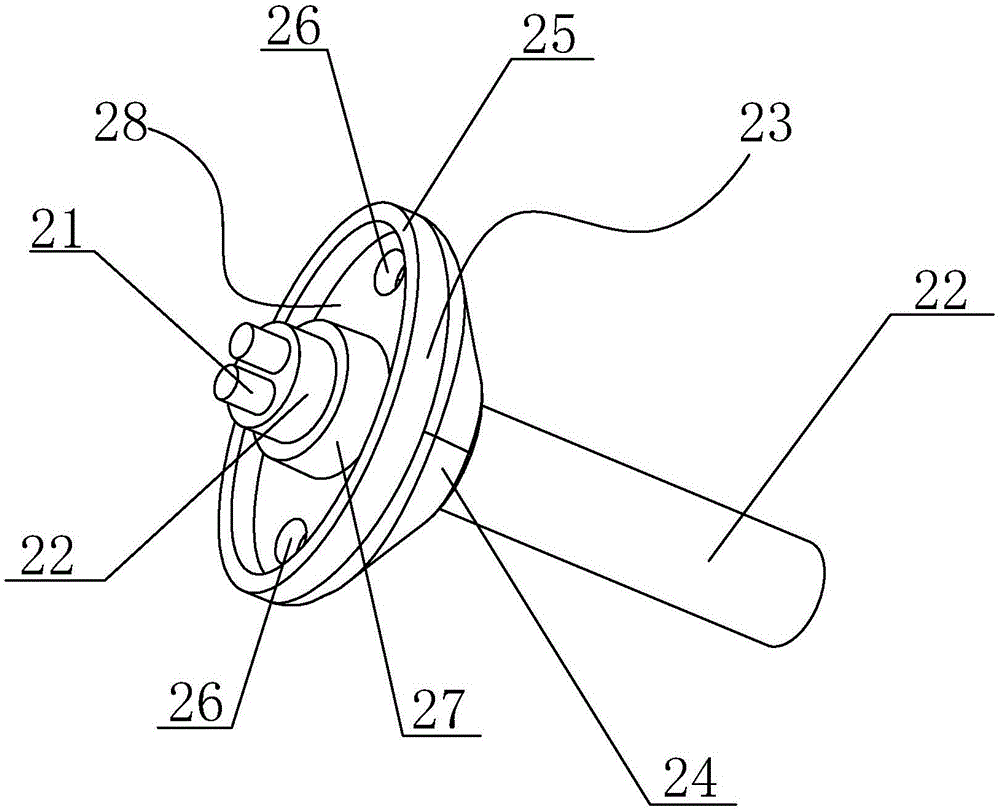

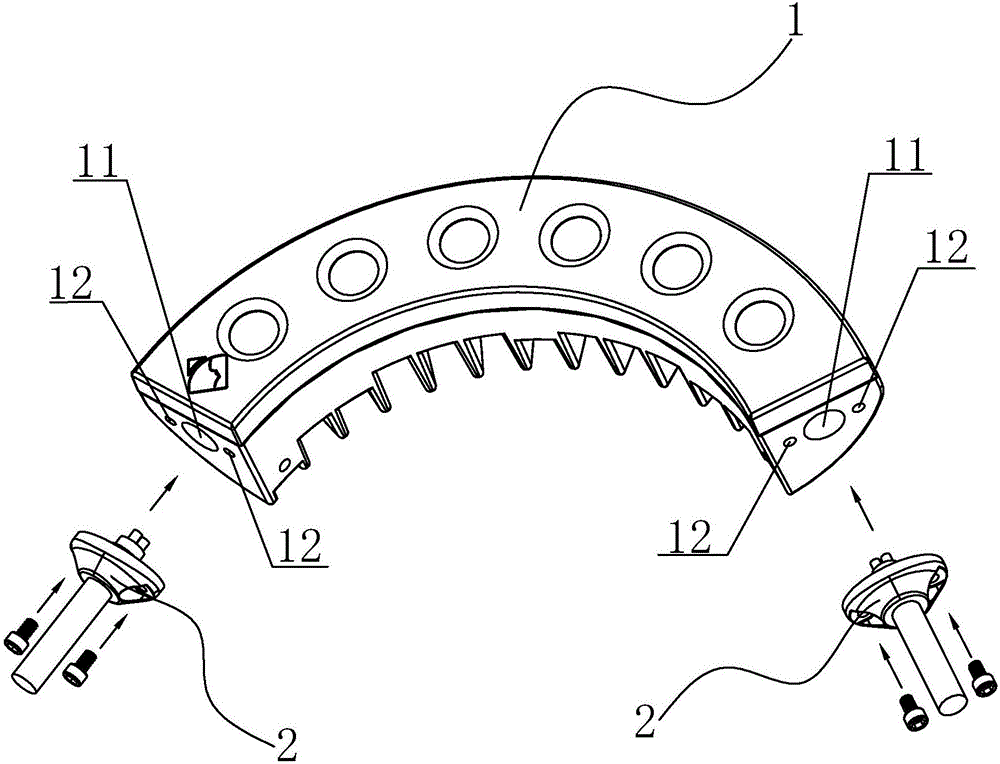

[0015] refer to Figure 1-Figure 3 , an outlet structure applied to a corrugated lamp according to the present invention, comprising a corrugated lamp main body 1 and a waterproof power cord 2, there is a wiring hole 11 on the left and right sides of the corrugated lamp main body 1, and the waterproof power cord 2 passes through the wiring hole 11 Connected to the interior of the main body 1 of the corrugated light, the waterproof power cord 2 includes an electric wire 21, a protective layer 22 for wrapping the electric wire 21 and a plug 23 arranged on the protective layer 22 for blocking the wiring hole 11, and the waterproof power cord 2 is integrated Forming, wherein, the plug 23 includes a slope 24, a bottom surface 25 for covering the wiring hole 11 and a plugging layer 27 for plugging the wiring hole 11. The plugging layer 27 protrudes from the bottom surface 25, and the plugging layer 27 and the wiring hole 11 are matched with each other, the edge of the wiring hole 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com