Sectional Scanning and Reconstruction Method of Green Tire

A technology of tire blank and scanning track, which is applied in the field of tire manufacturing, can solve the problems of inaccurate rubber strip arrangement simulation and troublesome operation of editing recipes, and achieve the effects of convenient editing of recipes, improving winding production efficiency, and reducing the number of inputs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

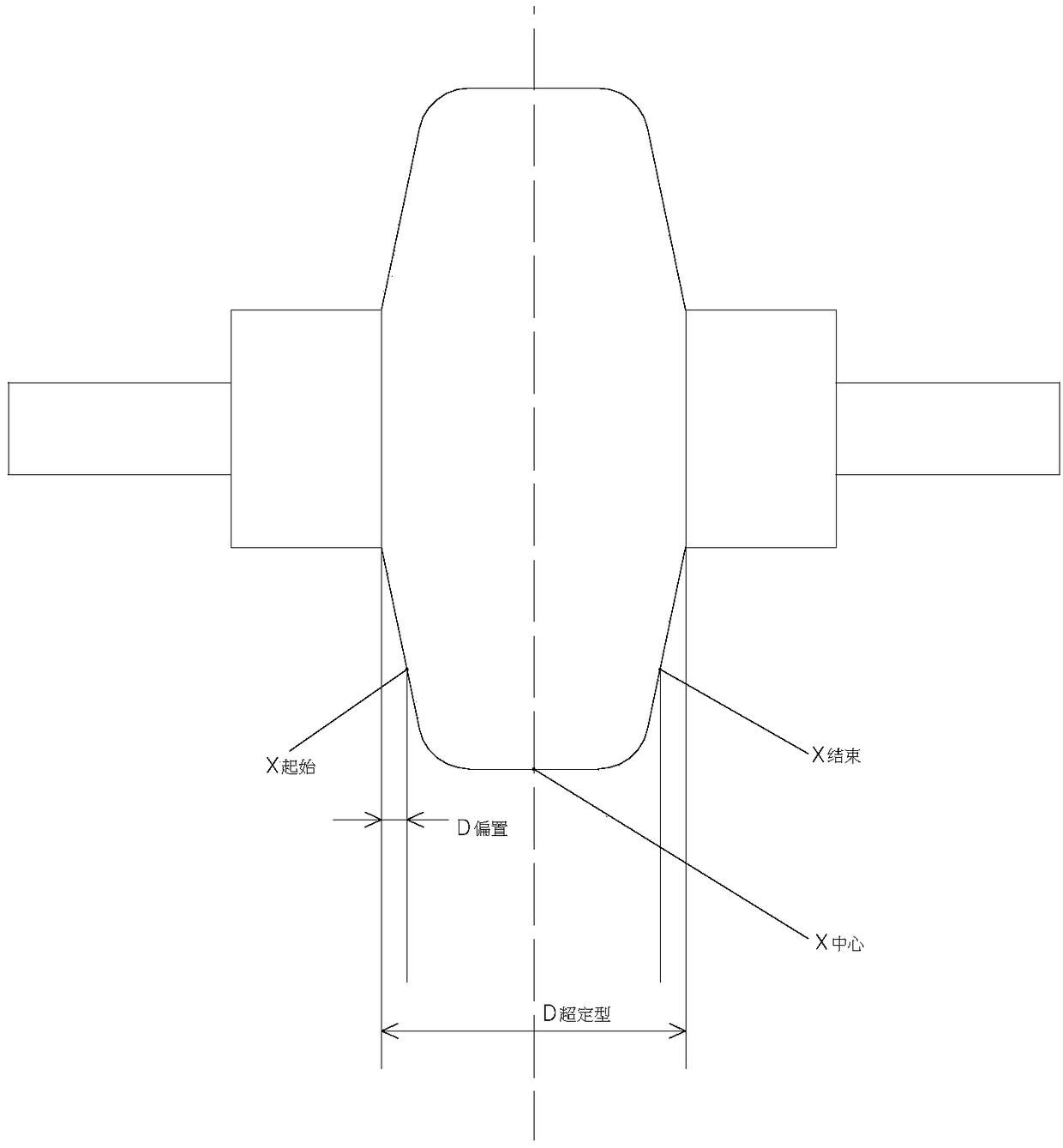

[0022] The present invention mainly uses the laser ranging sensor to measure the tire blank radius data, and then performs data processing on the measured data to generate the actual tire blank profile, and finally the winding simulation software uses the calculated tire blank profile to perform strip arrangement simulation to obtain more accurate simulation data. The specific plan has the following aspects:

[0023] 1. Write a PLC program based on Logix5000 software to collect 500 point radius values of the green tire section where the laser distance measuring sensor measures, and collect 4 tire blank section data in total.

[0024] 2. Use FactoryTalk View SE software and VBA to process the tire blank profile data to obtain the actual tire blank profile.

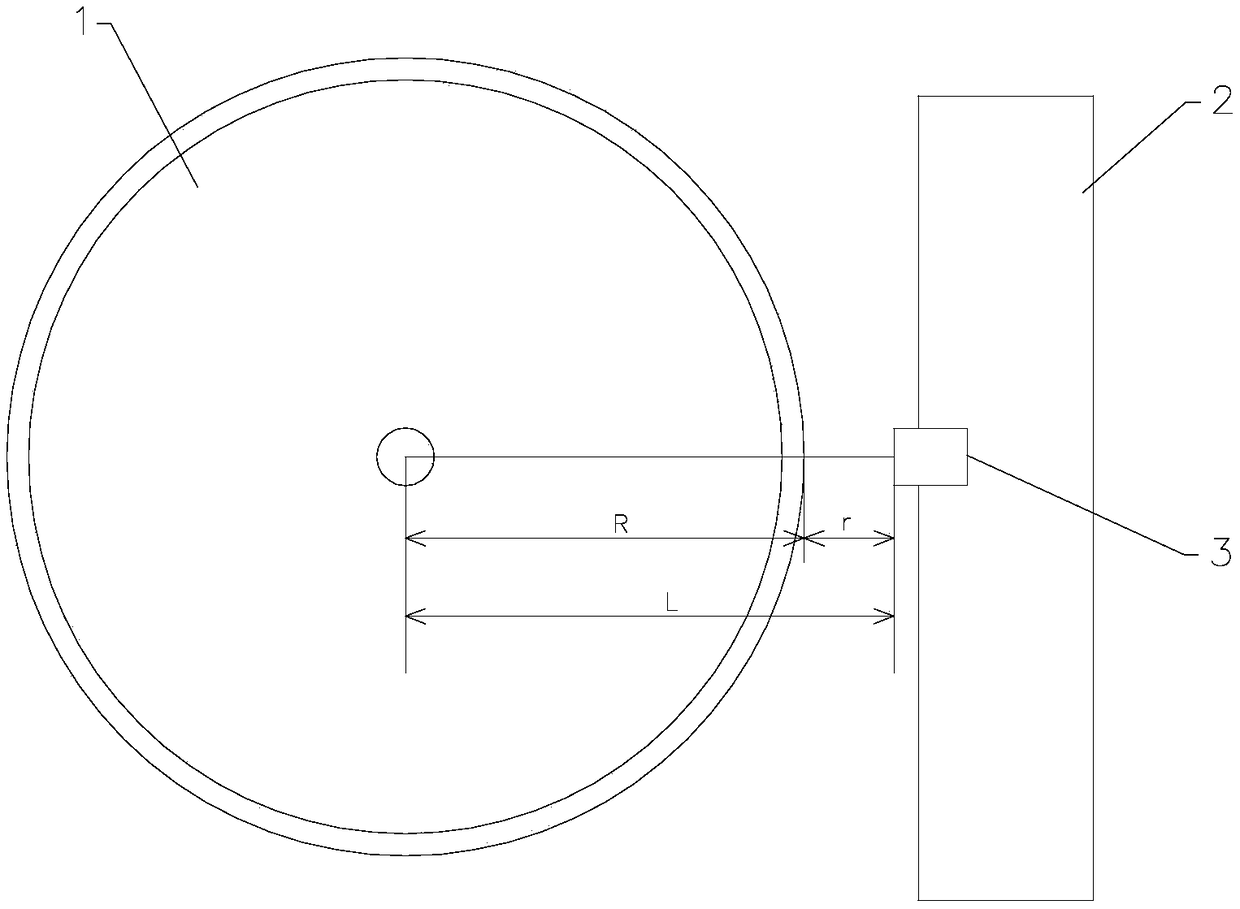

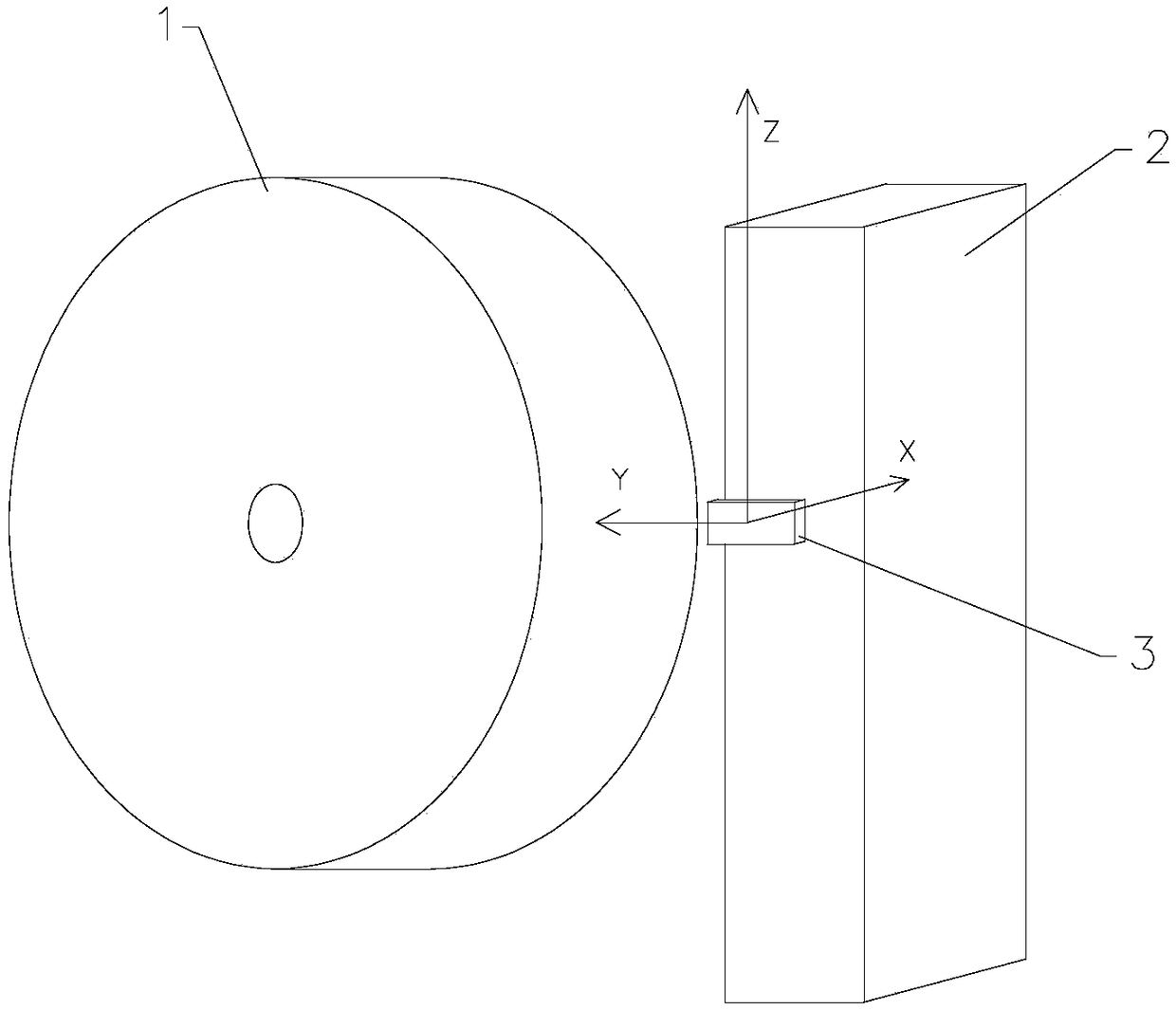

[0025] figure 1 It shows a schematic view of the relative position of the laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com