A general-purpose online measurement device for laser gyro mirrors

A laser gyroscope and measuring device technology, applied in the direction of testing optical performance, etc., can solve the problems of poor processing surface type and surface defect grade, lack of versatility, inability to perform precise optical polishing, etc., to meet the air tightness, reduce Residual reflectivity requirements, the effect of good glossy glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0029] The invention relates to an online measurement device for the performance of a laser gyro reflector, which is used to measure the performance change of the reflector under the operating environment of the laser gyro. The performance of the reflector usually includes reflectivity (total loss), scattering, absorption, optical constants, etc. This embodiment implements online measurement of the reflectivity (total loss) of the laser gyro mirror.

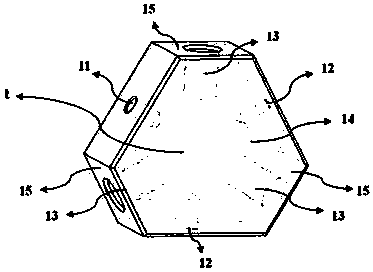

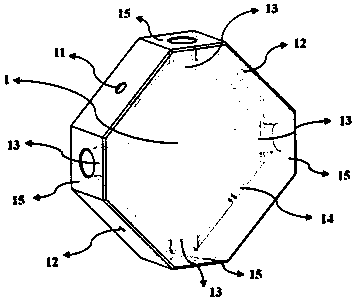

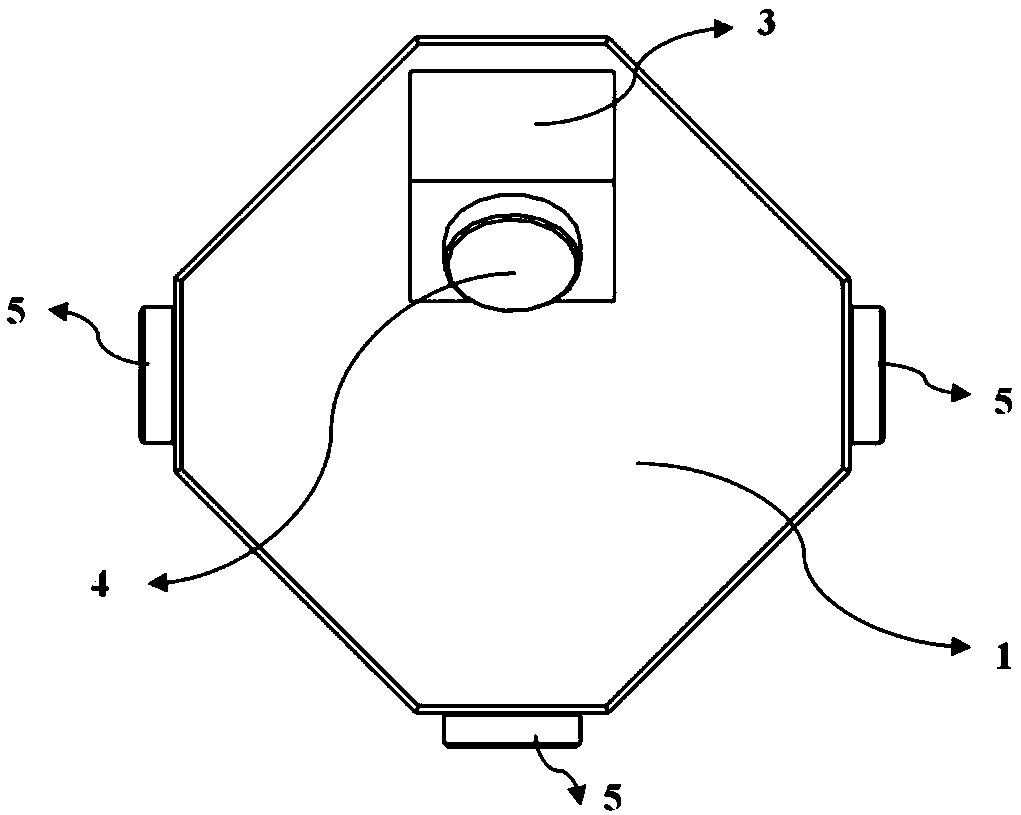

[0030] see figure 1 , image 3 , Figure 4 , the reflector to be tested in this embodiment corresponds to the quadrilateral laser gyroscope cavity 1, the cavity material is glass ceramics, the cavity outer size is 900mm*900mm, and the thickness is 30mm. The cavity is a decahedron, including four gas storage holes and corresponding Photoresist area, annular capillary hole, two anodes, one cathode, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com