Pedal device for drum

A pedal and beater technology, which is applied to instruments, percussion instruments, musical instruments, etc., can solve problems such as the inability to drive the pedal smoothly and the decline of pedal operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

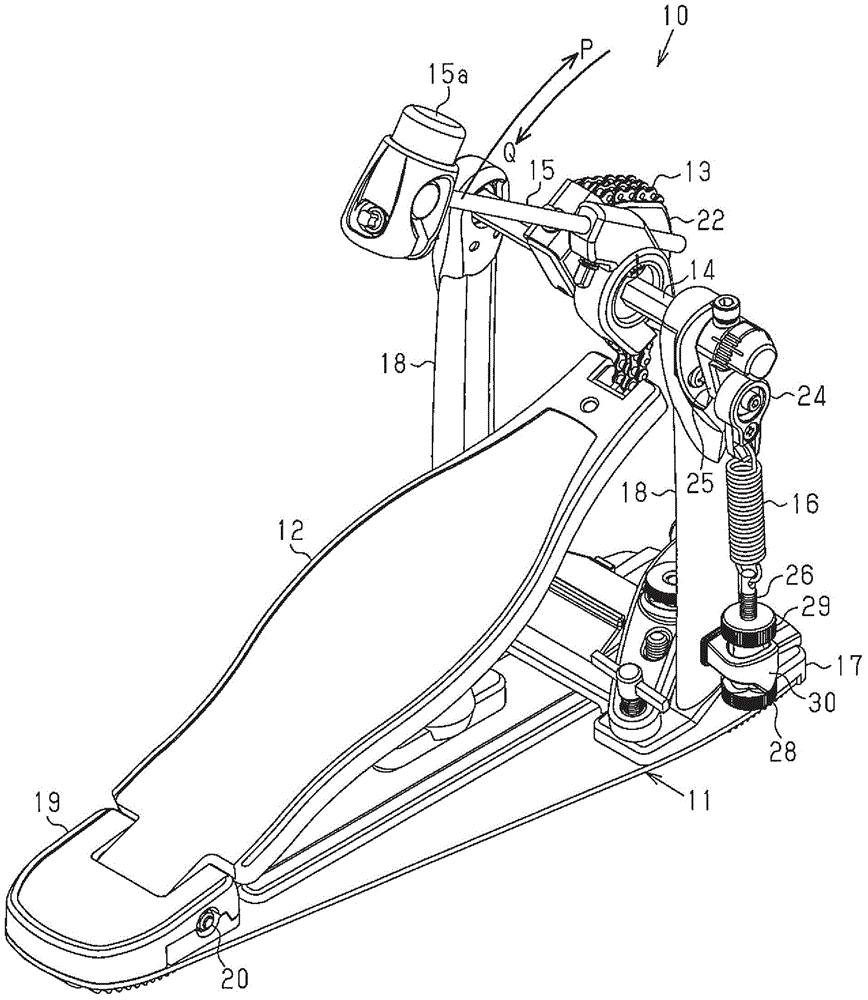

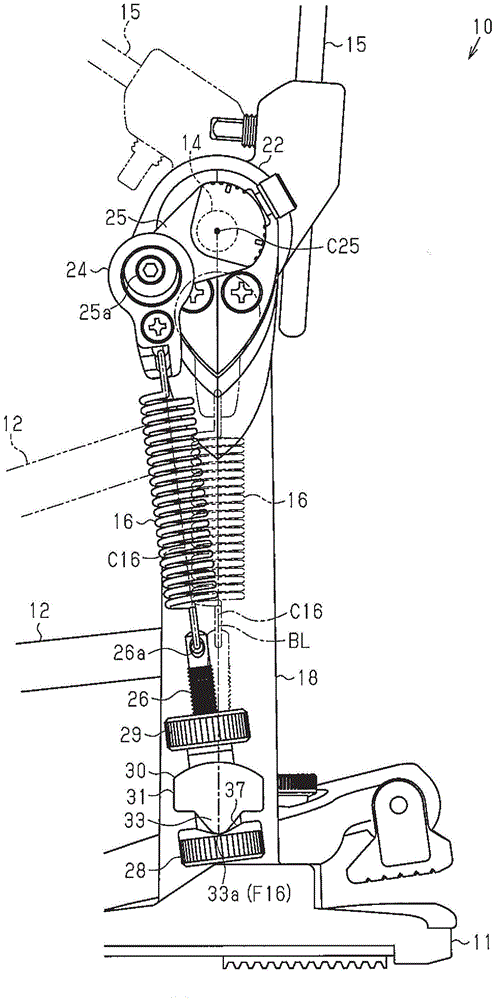

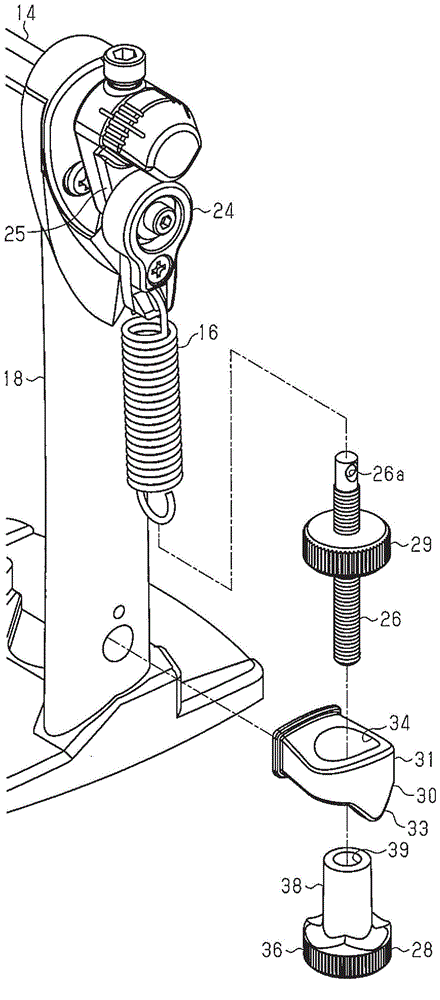

[0020] Refer below Figure 1 ~ Figure 7B An embodiment in which the drum pedal device of the present invention is embodied will be described.

[0021] Such as figure 1 As shown, the drum pedal 10 includes an apparatus main body 11 , a pedal 12 , a chain belt 13 as a transmission member, a shaft 14 , a beater 15 , and a tension coil spring 16 . The device main body 11 is composed of a base 17 and a pair of pillars 18 extending upward from the front end of the base 17 . The pair of struts 18 is arranged with a space between the two struts 18 . A heel portion 19 is attached to the rear end of the base 17 . The rear end of the pedal 12 is rotatably mounted to the heel portion 19 via a support shaft 20 . The front end of the pedal 12 is arranged between a pair of struts 18 .

[0022] The shaft 14 is rotatably supported to the upper ends of a pair of struts 18 . A beater 15 and a roller 22 are attached substantially at the center of the shaft 14 . One end of the chain belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com