A material processing device with good crushing function

The technology of a crushing device and a processing device is applied in the directions of grain processing, packaging, transportation and packaging to achieve the effect of being conducive to popularization and simple and practical in structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in conjunction with the following examples.

[0017] Application Scenario 1:

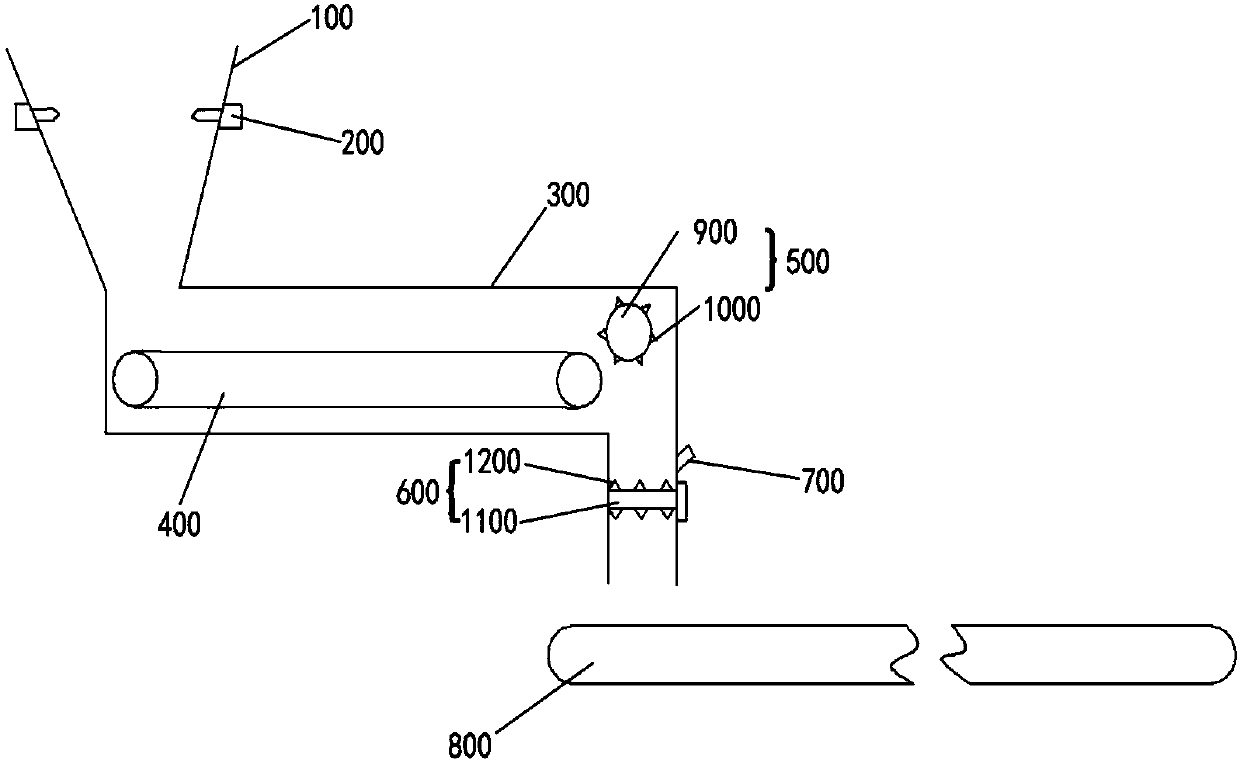

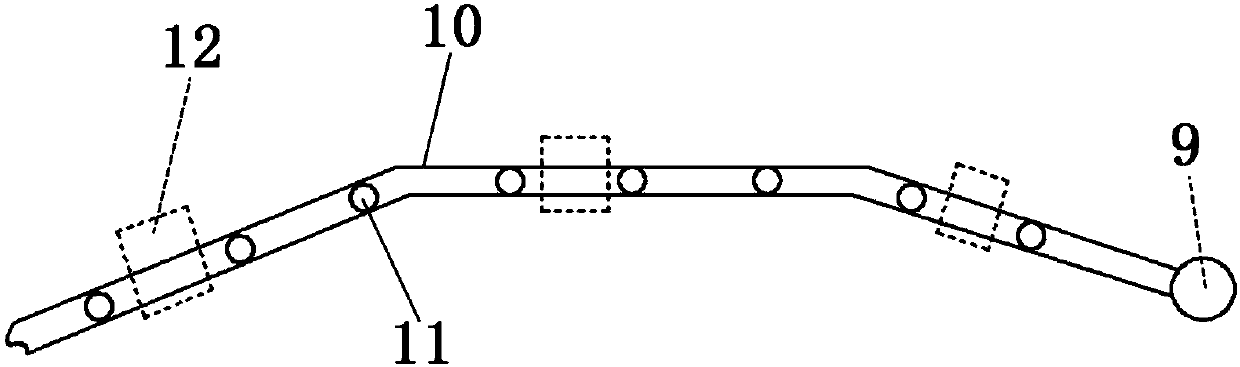

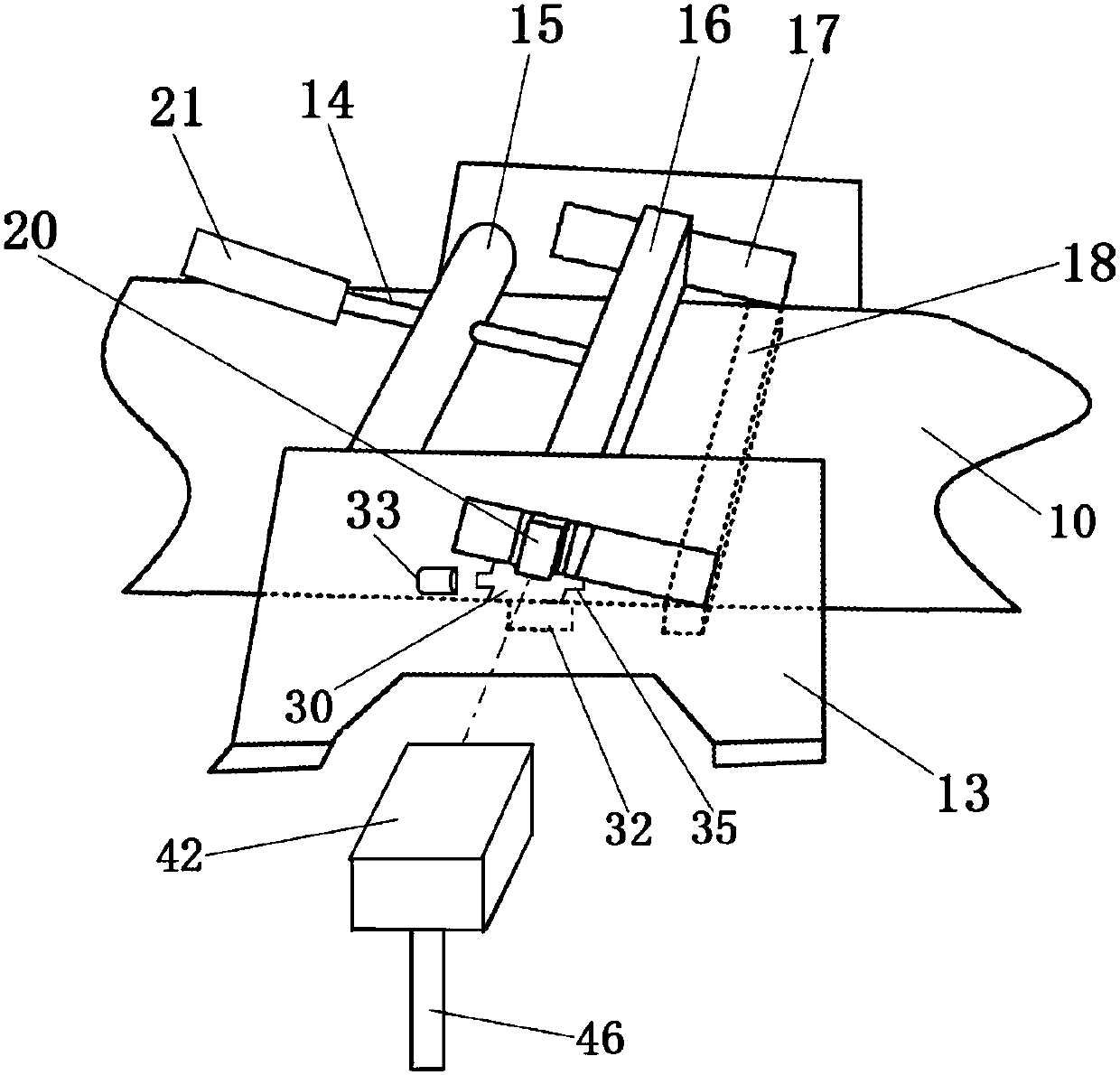

[0018] Such as figure 1 A material processing device with a good crushing function is shown, including a hopper 100, a hydraulic puncture needle 200, a housing 300, a transfer belt 400, a first crushing device 500, a second crushing device 600, an air nozzle 700 and a conveyor belt 800 The two hydraulic puncture needles 200 are symmetrically arranged on the side wall of the hopper 100, and are driven by hydraulic pressure to perform a reciprocating puncture movement, which is used to break the bags contained in the material; the transfer belt 400 is arranged on the casing In 300, the first crushing device 500 is set on the upper right of the end of the transfer belt to perform preliminary crushing on the materials that will fall into the outlet of the casing 300. The first crushing device 500 includes a drum 900 and a drum 900 a plurality of edge k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com